Fenofibrate nanometer suspension and preparation method thereof

A nanosuspension and fenofibrate technology, which is applied in the field of fenofibrate nanosuspension and its freeze-dried powder, can solve the problems of difficult to solve the influence of medication, bioavailability cannot reach 100%, and the like, Achieve the effect of low cost, easy to scale up industrial production, and avoid toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

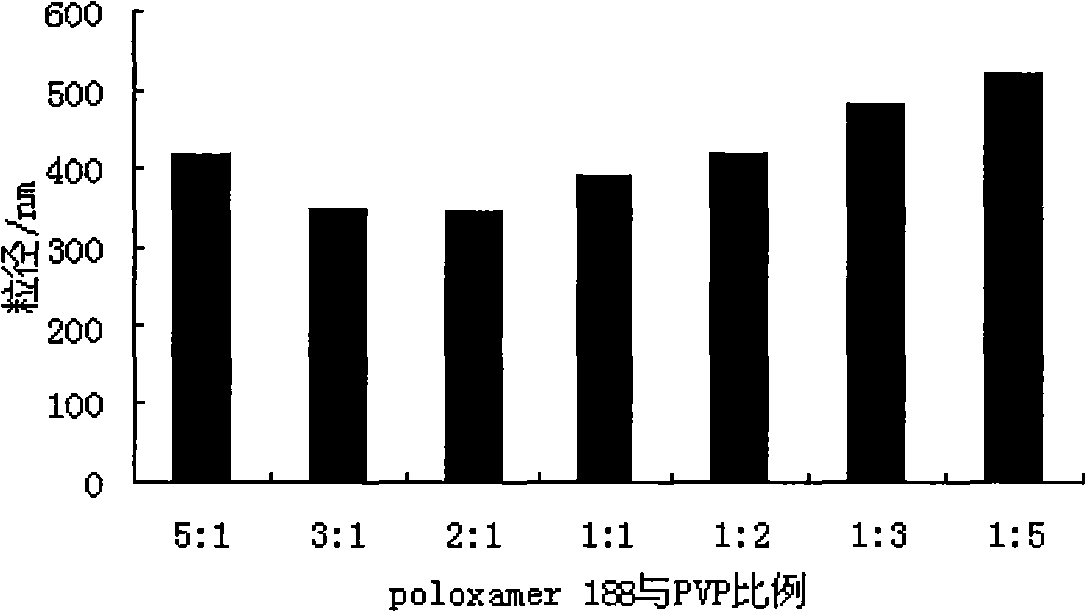

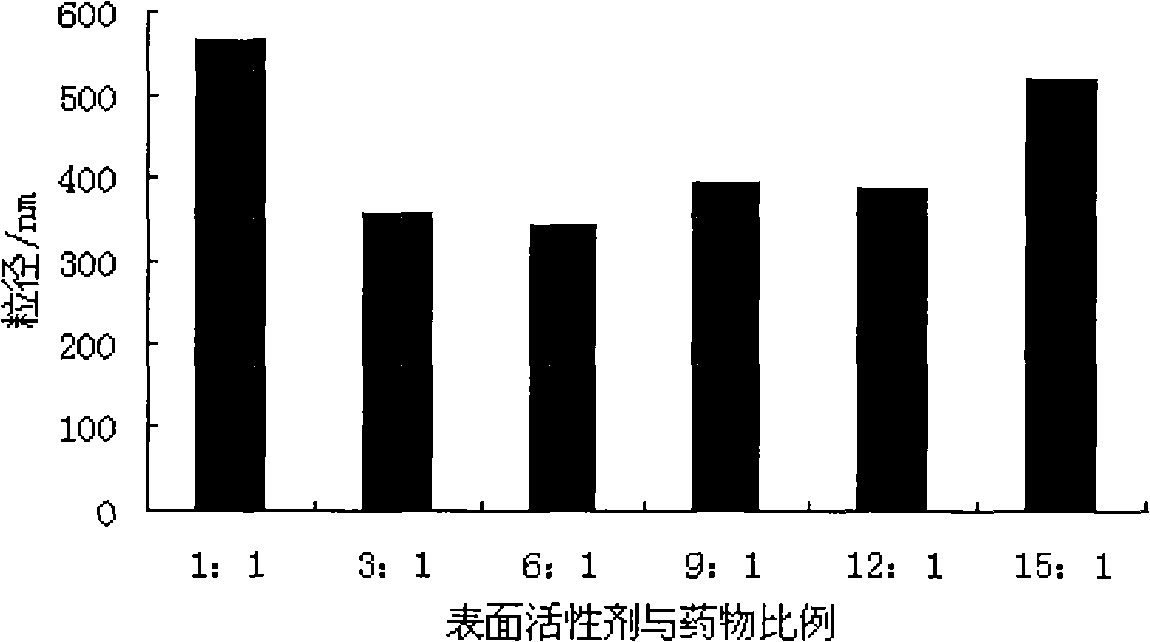

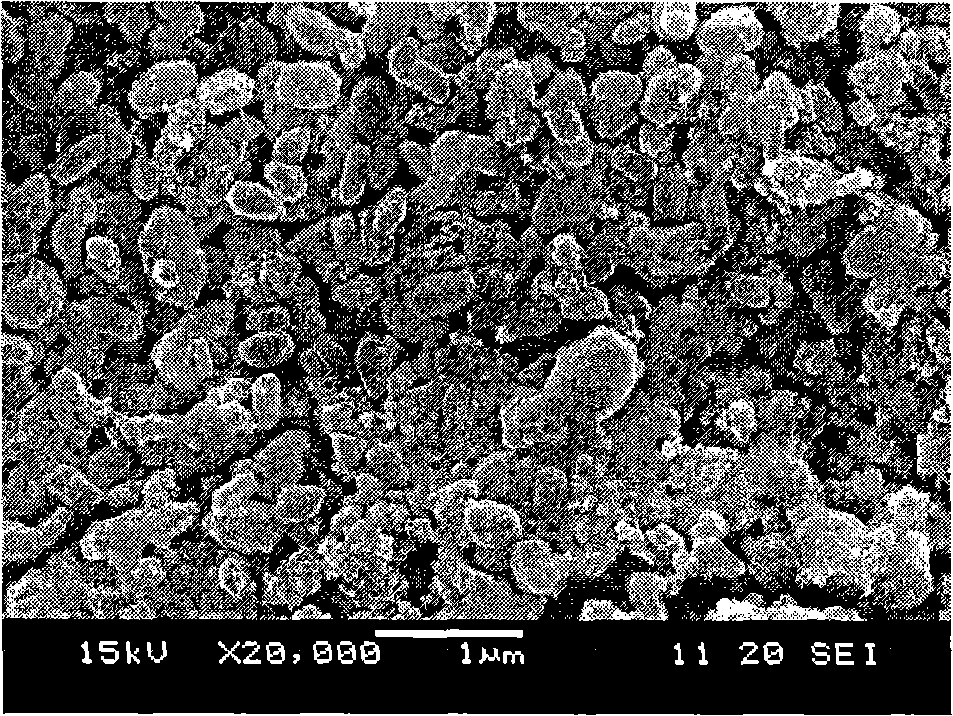

Embodiment 1

[0036] Weigh 500 mg of poloxamer 188, add 250 mg of polyvinylpyrrolidone into 50 ml of three-distilled water, heat at a slight temperature to dissolve completely, add 250 mg of fenofibrate raw material, and then heat in a water bath at 85-90 ° C until the drug becomes molten; 10000 rpm Shear pre-emulsification for 3 minutes; high-pressure homogenization of the primary suspension under the conditions of 3 cycles at 300 bar, 3 cycles at 500 bar, and 12 cycles at 800 bar. During the homogenization process, keep the temperature above the melting point of fenofibrate, and then quickly freeze After cooling in the bath, a milky white nanosuspension was obtained, the measured particle diameter was 365nm, and the zeta potential was -38.54mv.

Embodiment 2

[0038] Weigh 1000mg of Poloxamer 188, add 500mg of polyvinylpyrrolidone into 50ml of three-distilled water, heat at a slight temperature to dissolve completely, add 250mg of fenofibrate raw material, and then heat in a water bath at 85-90℃ until the drug becomes molten; 10000rpm high Shear pre-emulsification for 3 minutes; high-pressure homogenization of the primary suspension under the conditions of 3 cycles at 300 bar, 3 cycles at 500 bar, and 12 cycles at 1500 bar. During the homogenization process, the temperature was maintained above the melting point of fenofibrate, and then quickly iced. After cooling in the bath, a milky white nanosuspension was obtained, with a measured particle diameter of 190 nm and a zeta potential of -34.61 mv.

Embodiment 3

[0040] Weigh 1000mg of poloxamer 188, add 1000mg of polyvinylpyrrolidone into 50ml of three-distilled water, heat at a slight temperature to dissolve completely, add 500mg of fenofibrate raw material, and then heat in a water bath at 85-90℃ until the drug becomes molten; 10000rpm high Shear pre-emulsification for 3 minutes; high-pressure homogenization of the primary suspension under the conditions of 3 cycles at 300 bar, 3 cycles at 500 bar, and 12 cycles at 1200 bar. During the homogenization process, the temperature was maintained above the melting point of fenofibrate, and then quickly iced. After cooling in a bath, a milky white nanosuspension was obtained, the measured particle diameter was 287nm, and the zeta potential was -34.57mv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com