Agricultural liquid ground cover film, preparation and use method thereof

A ground covering and liquid technology, which is applied in the field of agrochemicals, can solve the problems of poor heat preservation and moisture conservation, high cost of mulching film manufacturing, and difficulty in popularization and use, and achieve the effects of improving physical properties, avoiding secondary pollution, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

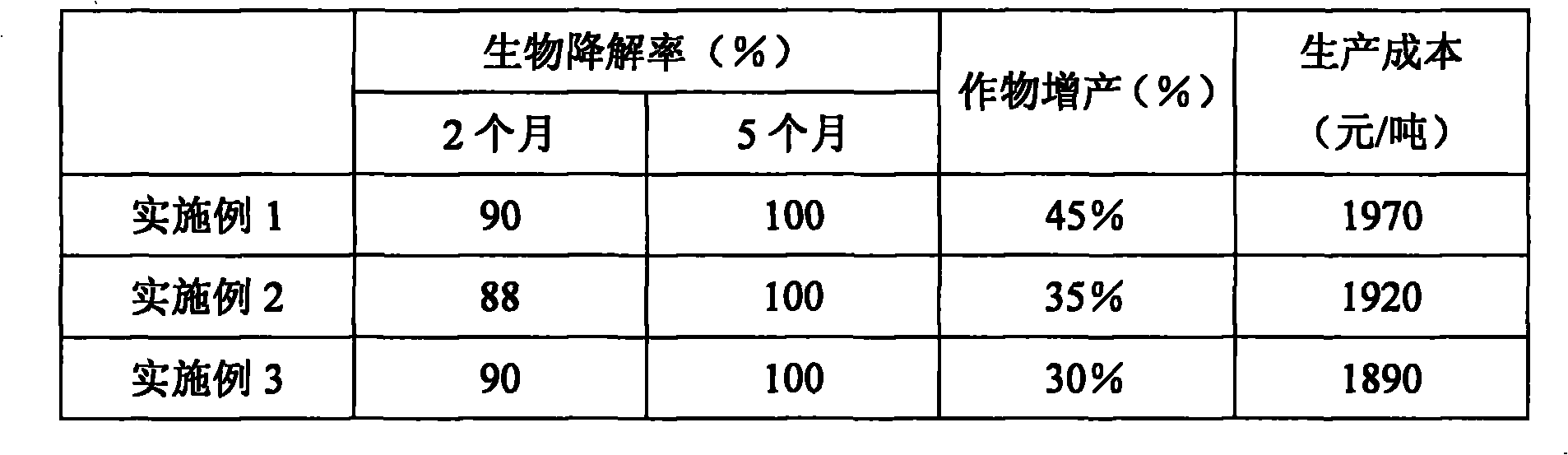

Embodiment 1

[0026] Example 1: Add 6 grams of chitin and 10 grams of gelatin to 50 grams of water to prepare a mixed solution; disperse 40 grams of sodium lignosulfonate in 70 grams of water, stir well, and then add 20 grams of modified starch in the solution , at 90°C, gelatinize for 45 minutes to form a transparent and viscous starch paste, then add the pre-prepared mixture of chitin and gelatin, and finally, add 4 grams of sodium dodecylbenzenesulfonate to the mixed in aqueous solution. Adjust the pH to 4, add 0.1 g of N,N-methylenebisacrylamide, and pass N at 50°C 2 Stir and polymerize for 2 hours to obtain an agricultural degradable liquid mulch film.

Embodiment 2

[0027] Example 2: Add 4 grams of chitin and 6 grams of gelatin to 40 grams of water to prepare a mixed solution; disperse 50 grams of sodium lignosulfonate in 88 grams of water, stir well, then add 10 grams of modified starch in the solution , at 78°C, gelatinize for 40 minutes to form a transparent and viscous starch paste, then add the pre-prepared mixture of chitin and gelatin, and finally, add 2 grams of sodium dodecylbenzenesulfonate to the mixed in aqueous solution. Adjust the pH value to 2, add 0.2 g of N, N-methylenebisacrylamide, and pass N at 45°C 2 Stir and polymerize for 1.5 hours to obtain an agricultural degradable liquid mulch film.

Embodiment 3

[0028] Example 3: Add 6 grams of chitin and 8 grams of gelatin to 45 grams of water to prepare a mixed solution; disperse 50 grams of sodium lignosulfonate in 73 grams of water, stir well, then add 15 grams of modified starch in the solution , at 80°C, gelatinize for 40 minutes to form a transparent and viscous starch paste, then add the pre-prepared mixture of chitin and gelatin, and finally, add 3 grams of sodium dodecylbenzenesulfonate to the mixed in aqueous solution. Adjust the pH value to 3, add 0.4 g of N, N-methylenebisacrylamide, and pass N at 40°C 2 Stir and polymerize for 1 hour to obtain an agricultural degradable liquid mulch film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com