System for dry cleaning and separating-recovering waste plastics

A technology of dry purification, separation and recovery, which is applied in plastic recycling, recycling technology, drying, etc. It can solve the problems that different types of plastics cannot be sorted, and the humidity of the feed material should not be too high, so as to avoid winding and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

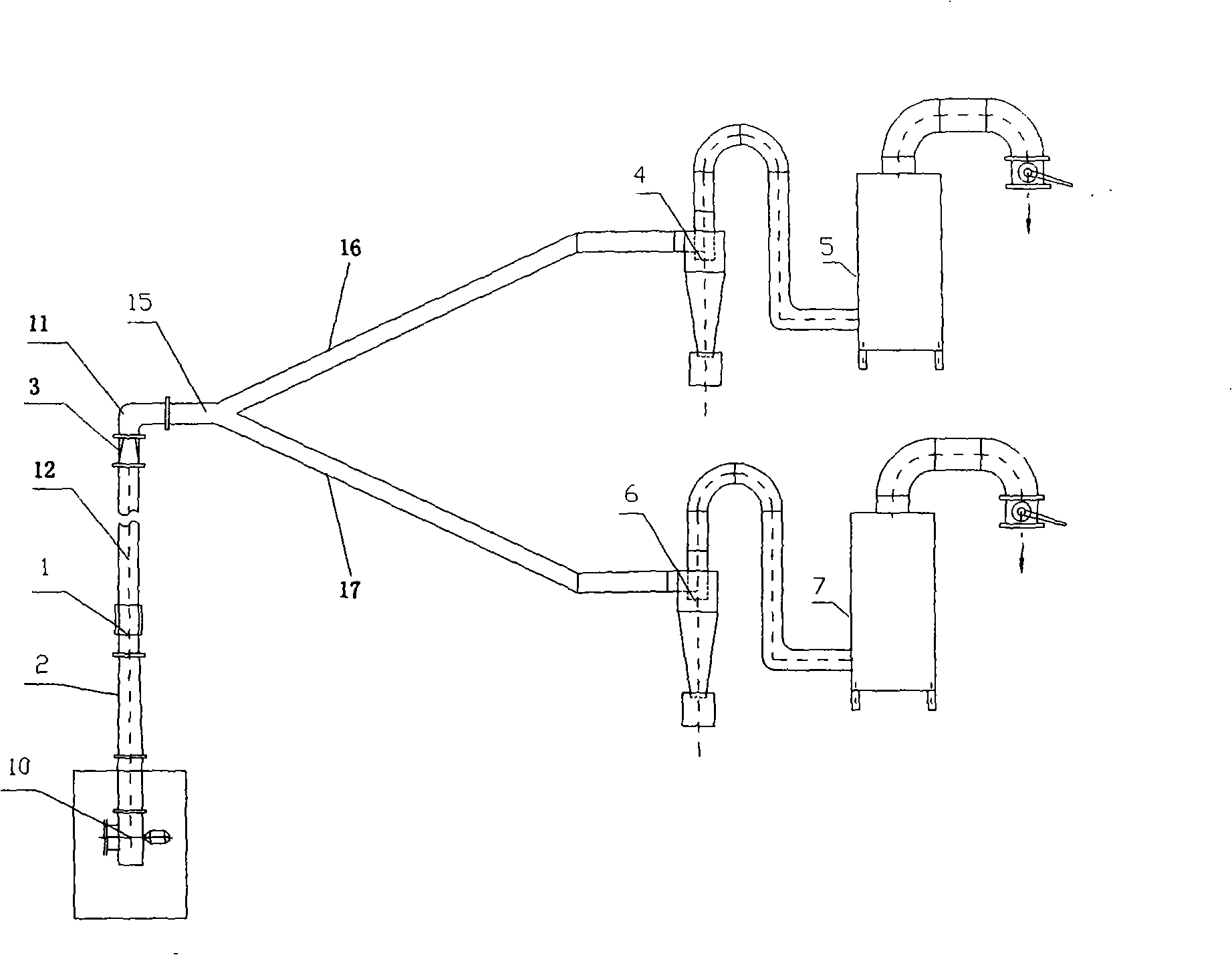

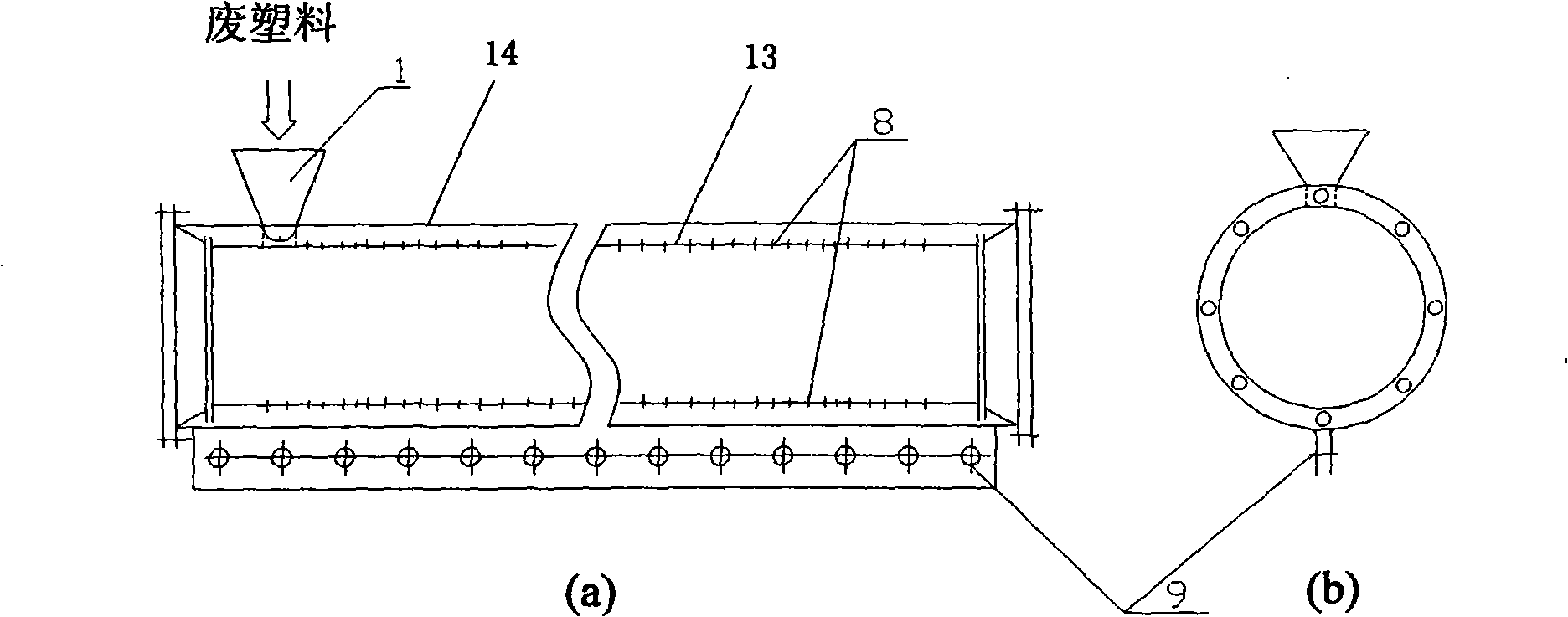

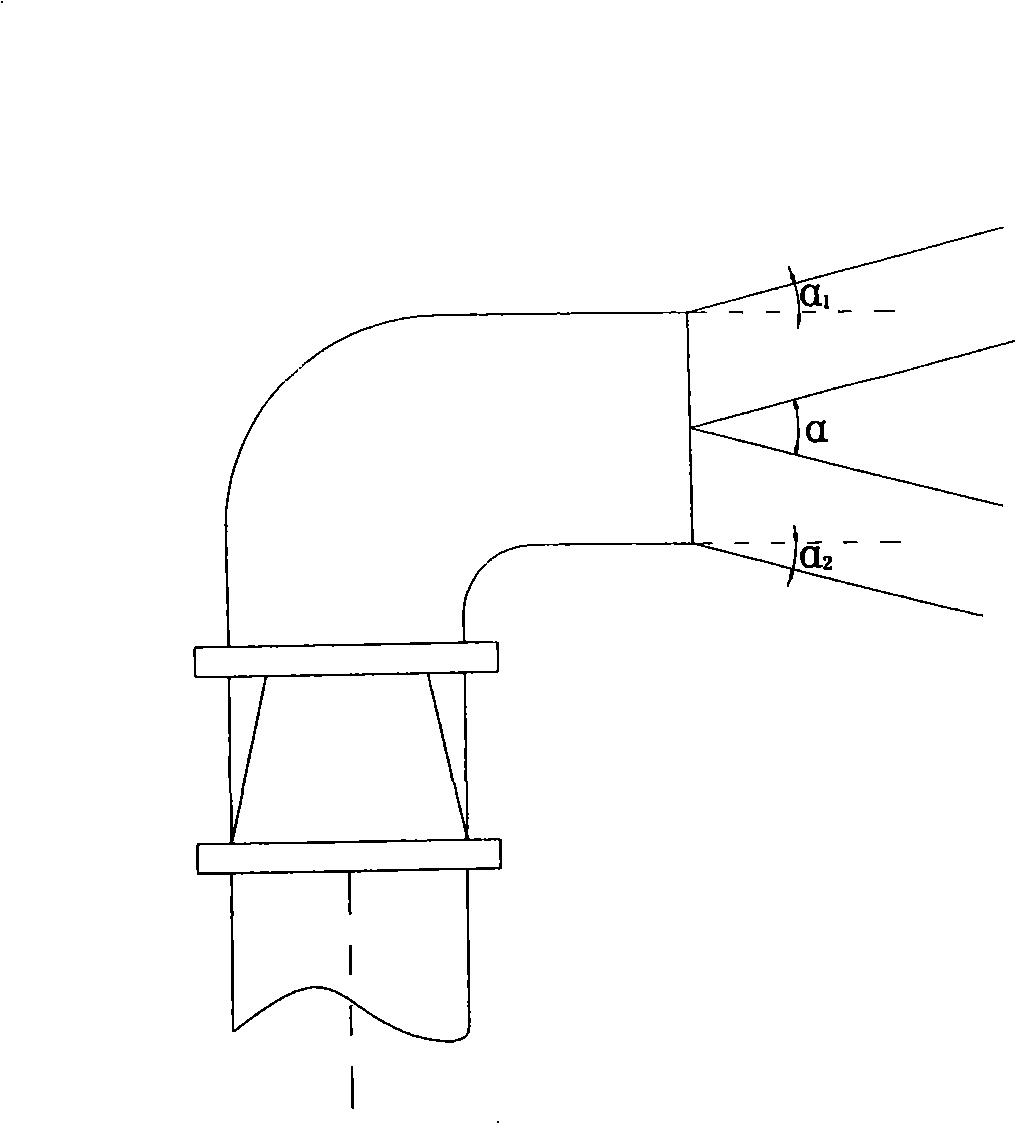

[0029] like figure 1 As shown, the mixed plastic film with soil, food residue and other sundries is crushed into fragments with a diameter of 5mm-500mm, and then put into the drying separation section 12 of the separation and purification system through the feeding port 1, and the drying temperature is from room temperature to 150 ℃, hot air is the best heat source for drying, and it can also be waste flue gas or even superheated steam, which is blown in from the inlet end. When there is no external drying heat source, the heating section 2 can be used to heat the air as the heat source. The impurities attached to the surface of the plastic film in the drying separation section 12 fall off due to drying, separate from the plastic film, and fall through the holes 8 (≤15mm) on the pipeline. The ad hoc dry separation pipe section has two layers and is composed of inner pipe 13 and outer pipe 14, as attached figure 2 As shown, there are holes 8 on the 13 sections of the inner pi...

Embodiment 2

[0033] like figure 1 As shown, the mixed plastic film with soil, food residue and other sundries is crushed into fragments with a diameter of 5mm-500mm, and then put into the drying separation section 12 of the separation and purification system through the feeding port 1, and the drying temperature is from room temperature to 150 ℃, hot air is the best heat source for drying, and it can also be waste flue gas or even superheated steam, which is blown in from the inlet end. When there is no external drying heat source, the heating section 2 can be used to heat the air as the heat source. The impurities attached to the surface of the plastic film in the drying separation section 12 fall off due to drying, separate from the plastic film, and fall through the holes 8 (≤15mm) on the pipeline. The ad hoc dry separation pipe section has two layers and is composed of inner pipe 13 and outer pipe 14, as attached figure 2As shown, there are holes 8 on the 13 sections of the inner pip...

Embodiment 3

[0037] like figure 1 As shown, the mixed plastic film with soil, food residue and other sundries is crushed into fragments with a diameter of 5mm-500mm, and then put into the drying separation section 12 of the separation and purification system through the feeding port 1, and the drying temperature is from room temperature to 150 ℃, hot air is the best heat source for drying, and it can also be waste flue gas or even superheated steam, which is blown in from the inlet end. When there is no external drying heat source, the heating section 2 can be used to heat the air as the heat source. The impurities attached to the surface of the plastic film in the drying separation section 12 fall off due to drying, separate from the plastic film, and fall through the holes 8 (≤15mm) on the pipeline. The ad hoc dry separation pipe section has two layers and is composed of inner pipe 13 and outer pipe 14, as attached figure 2 As shown, there are holes 8 on the 13 sections of the inner pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com