Waste ring-pull can surface paint remover and preparation method and application thereof

A technology of pop-top cans and paint remover, which is applied in the field of paint removal and can solve the problems of cumbersome treatment process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

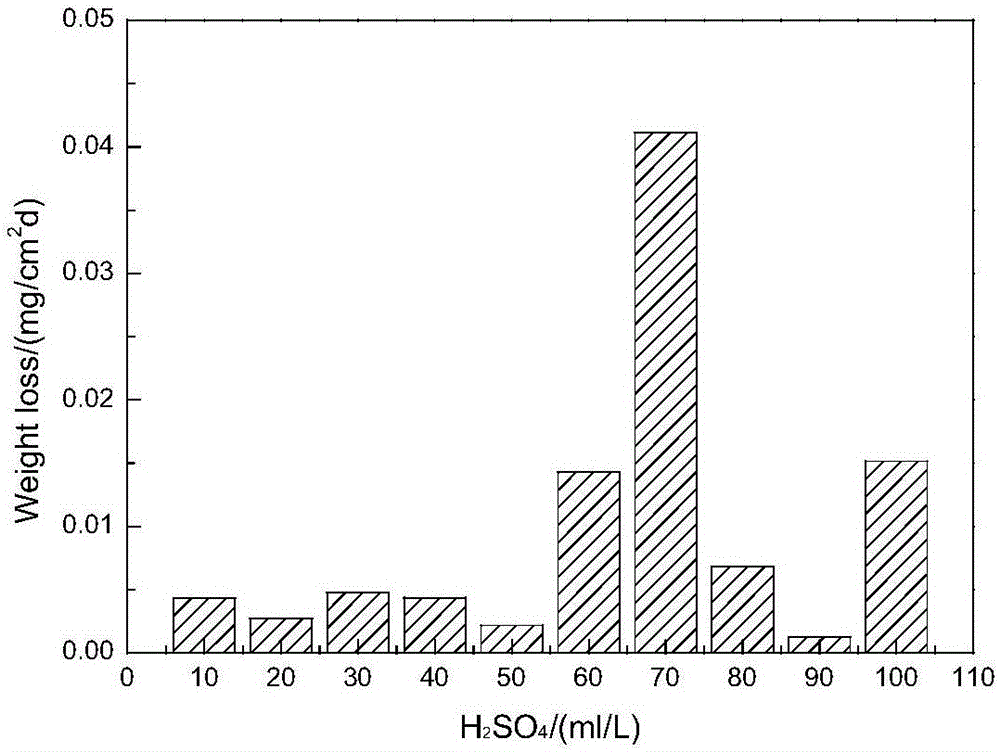

[0029] figure 1 For different sulfuric acid (H 2 SO 4 ) concentration of paint remover after paint removal, the weight loss diagram of the specimen shows that the corrosion weight loss is the largest when the sulfuric acid concentration is 70ml, and the corrosion weight loss is the smallest when the sulfuric acid concentration is 90ml. The order of corrosion weight loss is: 70ml>100ml>60ml>80ml>30ml> 10ml>40ml>20ml>50ml>90ml.

[0030] The comparison shows that concentrated sulfuric acid with a concentration of 70ml / L has the best paint removal effect, the paint removal temperature is normal temperature, and the paint removal time is 10 minutes.

Embodiment 2

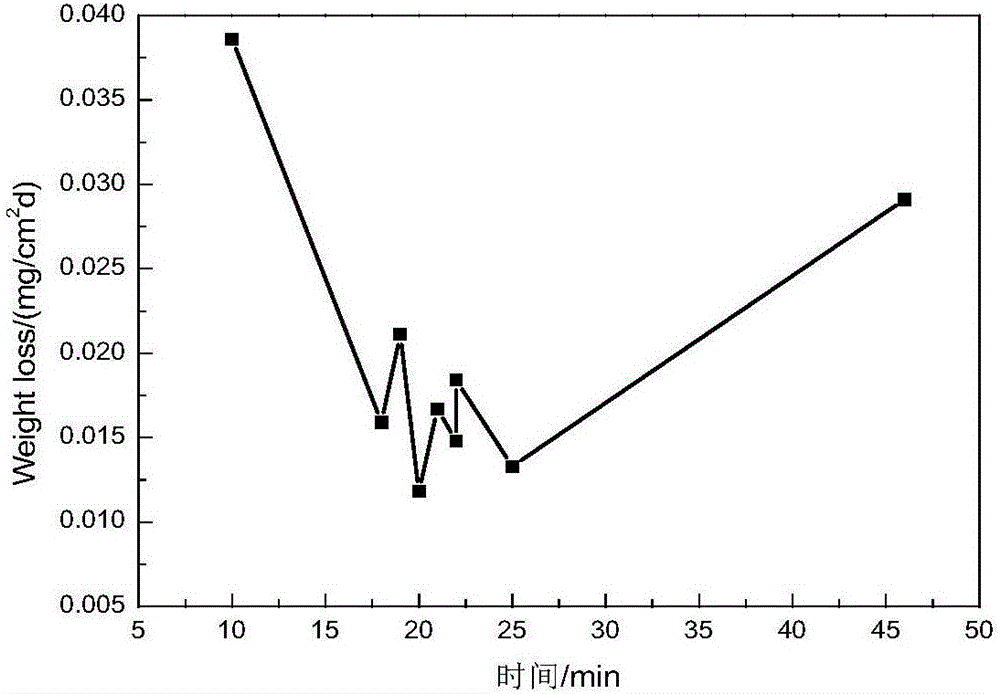

[0032] figure 2 The curve of time and corrosion weight loss shows that 2g / L surfactant is added in the concentrated sulfuric acid solution of 70ml / L. The corrosion weight loss is the largest at 10 minutes, followed by 46 minutes, and finally concentrated around 16 minutes to 25 minutes. It can be seen from Table 1 that the surfactant added when the corrosion weight loss is the largest is nonylphenol polyoxyethylene (NP-10).

[0033] Table 1 adds the composition, weight loss and paint removal result of each paint remover formulation of surfactant

[0034]

[0035] The comparison shows that the concentrated sulfuric acid with NP-10 has the best paint removal effect.

Embodiment 3

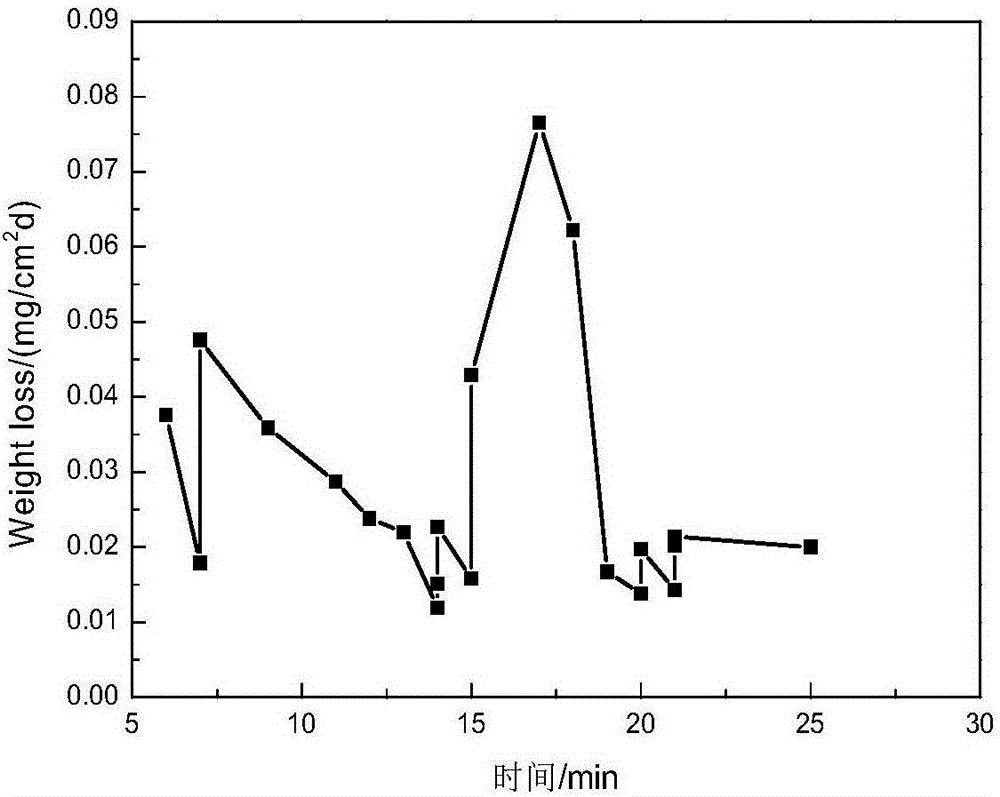

[0037] image 3 The curve of time and corrosion weight loss shows that 2g / L additive is added in 70ml / L concentrated sulfuric acid solution. It can be seen from the curve in the figure that the corrosion weight loss is the largest at 17 minutes, followed by 18 minutes, 7 minutes, and 15 minutes, and finally concentrated around 8 minutes to 15 minutes, and 19 minutes to 25 minutes. In conjunction with Table 2, it can be seen that the additive added when the corrosion weight loss was the largest was sodium lauryl sulfate, and what was added in 7min was linear alkylbenzene sulfonate sodium (LAS), what was added in 18min was hexamethylenetetramine, and in 15min Trisodium citrate was added.

[0038] Table 2 Adds the composition, weight loss and paint removal results of each paint remover formulation with additives

[0039]

[0040] Taking economic and environmental factors into account, adding 2g / L of LAS, the paint remover has the best effect on removing the surface paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com