Preparation method of high-purity garlic trithiodipropylene

A technology for trithiodipropylene and trithiodipropylene oil, which is applied in the field of preparation of high-purity garlic trithiopropylene, can solve the problems of low purity of garlic trisulfide and not suitable for medical use, and achieves the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the present embodiment, the preparation method of high-purity garlic trithiodipropylene is as follows:

[0027] (1) Garlic is peeled and crushed, placed in the air for 10 minutes, the garlic oil is extracted by steam distillation technology, the crushed garlic is directly mixed with three times the mass of water, heated to boiling with a volatile oil extraction device, the garlic volatile oil is collected, and distilled The time is 30 minutes;

[0028] (2) Add the garlic volatile oil in step (1) to C 18 In the chromatographic column, it is eluted with a methanol-water solution of 60% by volume to obtain a methanol-water solution of garlic trithiodipropylene;

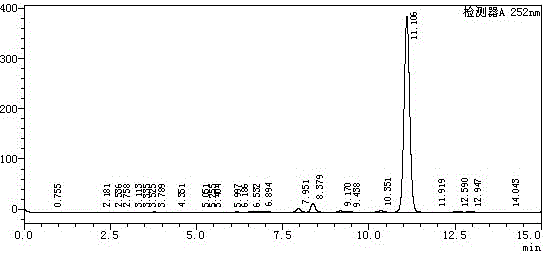

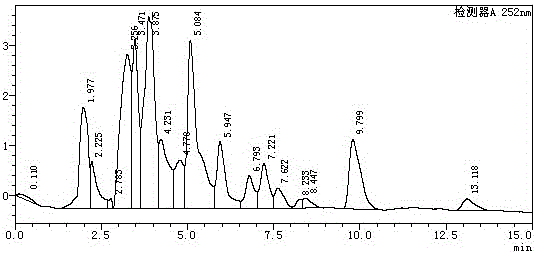

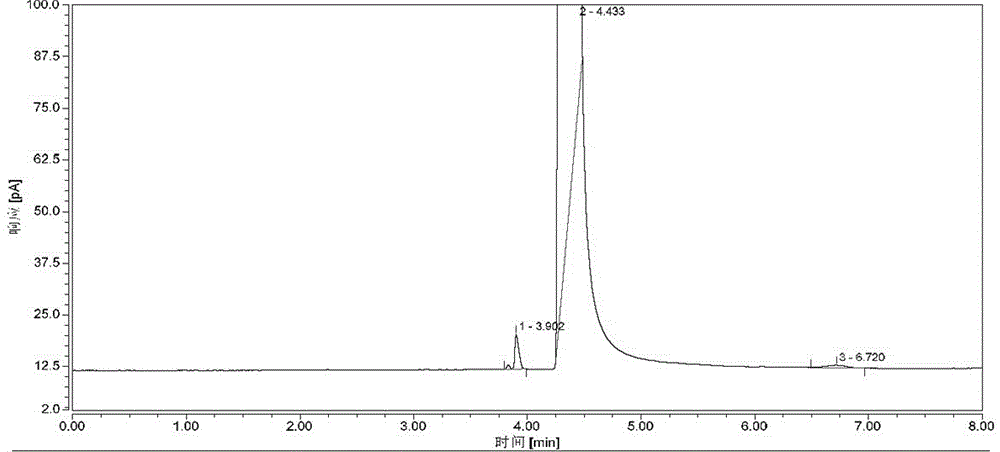

[0029] (3) the purity of the methanol-water solution of garlic trithiodipropylene obtained in the HPLC method detection step (2), the methanol-water solution of garlic trithiodipropylene with a purity greater than 90% is collected; the detected purity is low Collect in addition the methanol-water solution of ...

Embodiment 2

[0036] In the present embodiment, the preparation method of high-purity garlic trithiodipropylene is as follows:

[0037] (1) Garlic is peeled and crushed, placed in the air for 12 minutes, the garlic oil is extracted by steam distillation technology, the crushed garlic is directly mixed with three times the mass of water, heated to boiling with a volatile oil extraction device, the garlic volatile oil is collected, and distilled The time is 40 minutes;

[0038] (2) Add the garlic volatile oil in step (1) to C 8 In the chromatographic column, the methanol-water solution with a volume ratio of 80% is eluted to obtain the methanol-water solution of garlic trithiodipropylene;

[0039] (3) the purity of the methanol-water solution of garlic trithiodipropylene obtained in the HPLC method detection step (2), the methanol-water solution of garlic trithiodipropylene with a purity greater than 90% is collected; the detected purity is low Collect in addition the methanol-water solutio...

Embodiment 3

[0045] In the present embodiment, the preparation method of high-purity garlic trithiodipropylene is as follows:

[0046] (1) Garlic is peeled and crushed, placed in the air for 15 minutes, the garlic oil is extracted by steam distillation technology, the crushed garlic is directly mixed with three times the mass of water, heated to boiling with a volatile oil extraction device, the garlic volatile oil is collected, and distilled The time is 45 minutes;

[0047] (2) Add the garlic oil in step (1) to C 18 In the chromatographic column, the methanol-water solution with a volume ratio of 90% is eluted to obtain the methanol-water solution of trithiodipropylene;

[0048] (3) the purity of the methanol-water solution of garlic trithiodipropylene obtained in the HPLC method detection step (2), the methanol-water solution of garlic trithiodipropylene with a purity greater than 90% is collected; the detected purity is low Collect in addition the methanol-water solution of 90% trithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com