Hydrophobic efficient VOC molecular sieve adsorbent and preparation method thereof

A molecular sieve and hydrophobic technology, applied in the field of hydrophobic high-efficiency VOC molecular sieve adsorbent and preparation, can solve the problems of reduced adsorption capacity and low regeneration efficiency, and achieve the effect of reduced adsorption, high regeneration efficiency, and no obvious decrease in adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

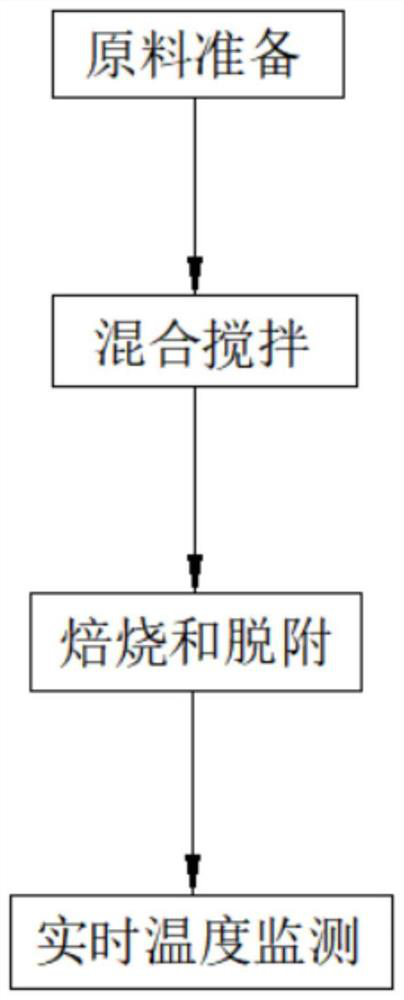

[0024] refer to figure 1 , the present invention proposes a hydrophobic high-efficiency VOC molecular sieve adsorbent, including the following raw materials in parts by weight: 95 parts of ZSM-5 molecular sieve, 45 parts of Beta molecular sieve, 45 parts of 13X molecular sieve, 50 parts of Y-type molecular sieve, 35 parts of silicon, aluminum 15 copies;

[0025] Its preparation method comprises the following steps:

[0026] S1: Raw material preparation: ZSM-5 molecular sieve with MFI structure is selected as the main material of the adsorption material, and the silicon-aluminum ratio of the molecular sieve with a mass percentage of 50% is selected as 23. In order to improve the hydrophobicity of the adsorbent, the silicon-aluminum ratio ∞ is preferred Pure silicon molecular sieves, and add Beta molecular sieves, 13X molecular sieves and Y-type molecular sieves, wherein the addition volume ratio of the Beta molecular sieves, 13X molecular sieves and Y-type molecular sieves is ...

Embodiment 2

[0031] refer to figure 1 , the present invention proposes a hydrophobic high-efficiency VOC molecular sieve adsorbent, including the following raw materials in parts by weight: 98 parts of ZSM-5 molecular sieve, 48 parts of Beta molecular sieve, 48 parts of 13X molecular sieve, 56 parts of Y-type molecular sieve, 45 parts of silicon, aluminum 15 copies;

[0032] Its preparation method comprises the following steps:

[0033] S1: Raw material preparation: ZSM-5 molecular sieve with MFI structure is selected as the main material of the adsorption material, and the silicon-aluminum ratio of the molecular sieve with a mass percentage of 80% is selected as ∞, and Beta molecular sieve, 13X molecular sieve and Y-type molecular sieve are added. The added volume ratio of Beta molecular sieve, 13X molecular sieve and Y-type molecular sieve is 3:3:2, and the ratio of molecular sieve is controlled by mass percentage, and the mass percentage of added components accounts for 50% of the tota...

Embodiment 3

[0038] refer to figure 1 , the present invention proposes a hydrophobic high-efficiency VOC molecular sieve adsorbent, including the following raw materials in parts by weight: 100 parts of ZSM-5 molecular sieve, 50 parts of Beta molecular sieve, 50 parts of 13X molecular sieve, 60 parts of Y-type molecular sieve, 50 parts of silicon, aluminum 20 copies;

[0039] Its preparation method comprises the following steps:

[0040] S1: Raw material preparation: ZSM-5 molecular sieve with MFI structure is selected as the main material of the adsorption material, and the silicon-alumina ratio of the molecular sieve with a mass percentage of 60% is selected as 55. In order to improve the hydrophobicity of the adsorbent, the silicon-aluminum ratio ∞ is preferred Pure silicon molecular sieves, and add Beta molecular sieves, 13X molecular sieves and Y-type molecular sieves, wherein the addition volume ratio of the Beta molecular sieves, 13X molecular sieves and Y-type molecular sieves is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com