Cross current intrinsic cycle ultrasonic and microwave leaching reactor and leaching method thereof

A technology of ultrasonic wave and reactor, which is applied in the leaching of active ingredients in Chinese herbal medicine, and in the field of leaching reactors with cross-flow internal circulation of ultrasonic and microwave, which can solve the problems of ultrasonic and microwave equipment limitations, uneven effect, and reduced efficiency. , to achieve the effect of improving leaching and reaction efficiency, strengthening fluid flow, and preventing the formation of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

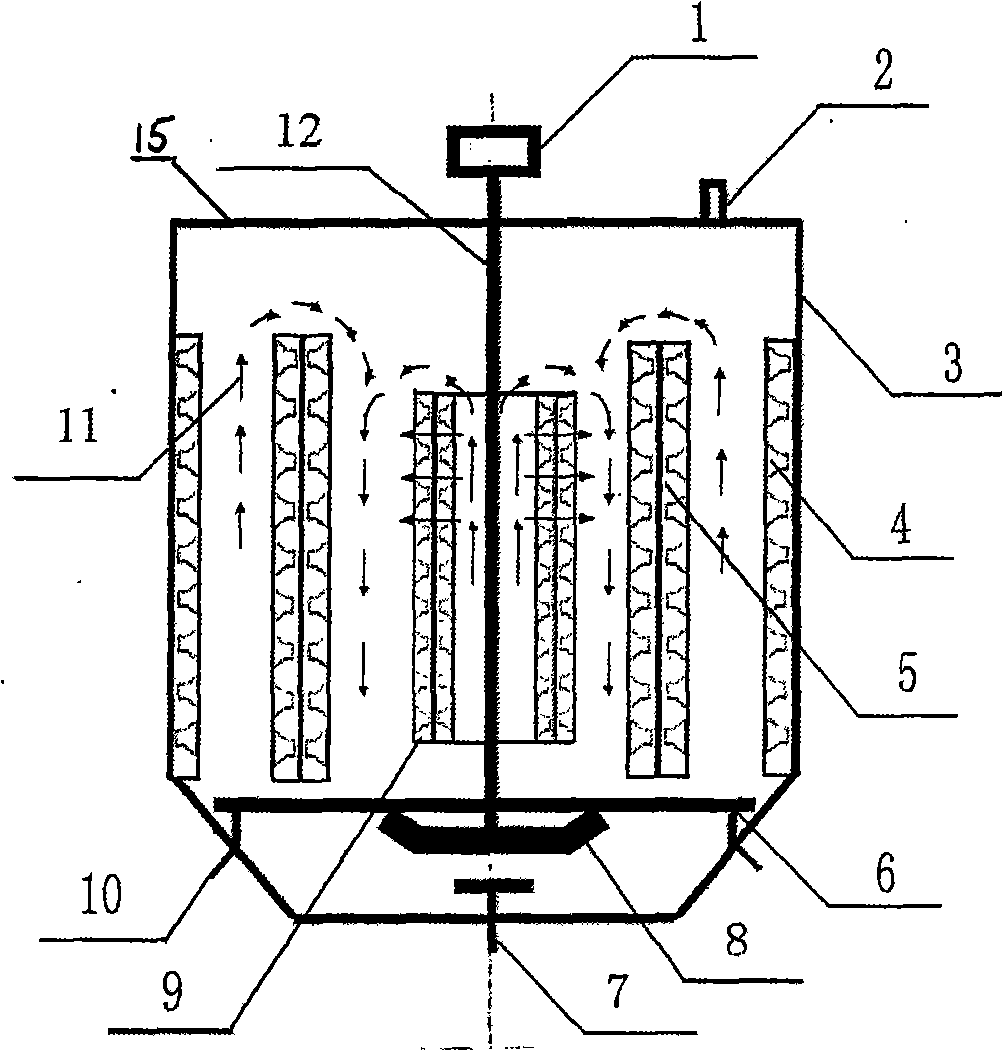

[0053] refer to Figure 1a and Figure 1b , to make a cross-flow internal circulation ultrasonic and microwave leaching reactor with three layers of ultrasonic vibrator rings, the reactor shell 3 is made of stainless steel into a cylinder with a height of 3500mm×diameter of 1500mm, and the bottom of the cylinder is trapezoidal The housing 3, the upper cover 15 of stainless steel is installed on the upper mouth of the reactor housing 3, and the upper cover 15 is provided with an air outlet 2 for adjusting the pressure in the tank; the shaft 12 of the agitator 1 and the shaft 12 are installed The stirring blade 8 passes through the upper cover 15 and is sealed and installed in the center of the reactor shell 3 .

[0054] The first layer of ultrasonic vibrator group ring 9 is composed of four vibrator boxes 16 arranged at equal intervals along the outer wall of the first layer of cylinder 13 and installed on the outer wall. The distance between the vibrator boxes 16 is 100mm. Th...

Embodiment 2

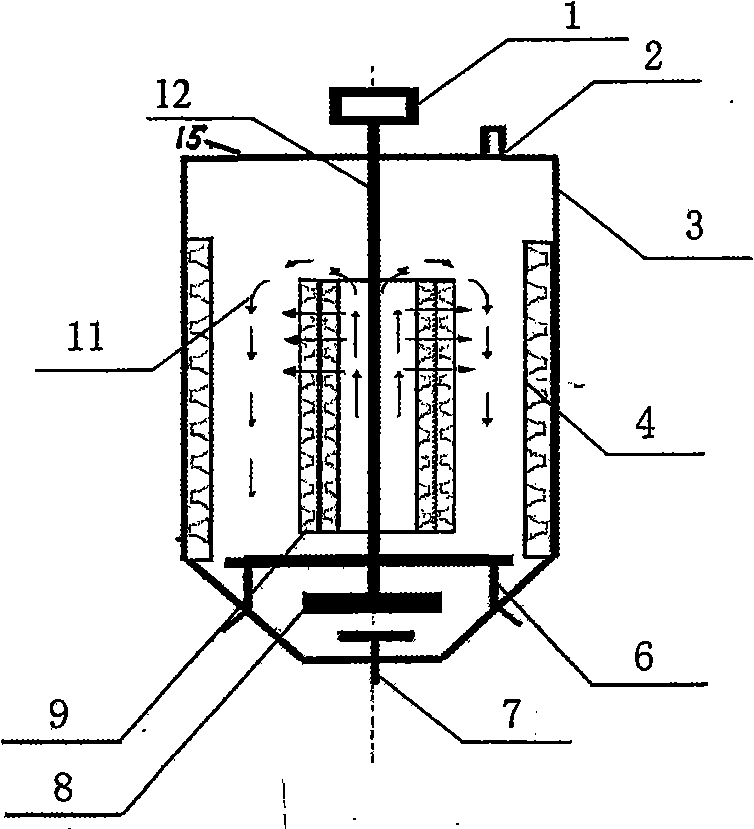

[0062] Referring to Figure 2, a cross-flow internal circulation ultrasonic and microwave leaching reactor with two layers of ultrasonic vibrator rings is produced. The reactor is made of stainless steel into a shell 3 with a height of 2500mm×diameter of 1200mm, and the bottom of the shell 3 is The upper cover 15 made of trapezoidal and cylindrical stainless steel material is installed on the shell 3 of the reaction kettle; the upper cover 15 is provided with an air outlet 2 for adjusting the pressure in the tank; The upper stirring blade 8 passes through the upper cover 15 and is sealed and installed in the center of the reactor shell 3 .

[0063] The first layer of ultrasonic vibrator ring 9 is composed of 4 vibrator boxes arranged in a circle. 11 transducer vibrators of the same size are installed in a vibrator box, each vibrator has a diameter of 50mm and a thickness of 50mm, and is arranged in a staggered manner at equal intervals. There are 2 transducers in the first row,...

Embodiment 3

[0068] exist Figure 1a and Figure 1b ,or Figure 2a and Figure 2b In the equipment, apply the method of the present invention to carry out the leaching of Liquiritigenin in Radix Glycyrrhizae, and its concrete processing step is as follows:

[0069] 1). Grinding medicinal licorice into 5-100 mesh granular grass powder;

[0070] 2). The grass powder crushed in step 1) is weighed according to the ratio of grass powder to water of 1 g: 20 liters; first put the liquid into the cross-flow internal circulation ultrasonic and microwave leaching reaction of Example 1 Put the solid powder into the kettle. Firstly, when the liquid feed liquid is fed, the aeration and stirring will be started. The gas introduced is air, and its flow rate is 1 / 10 of the volume. When the solid feed is fed, the mechanical agitation is turned on. Wherein the stirring speed is 60 rev / min;

[0071] 3). After the liquid and solid in step 2) are fully mixed, turn on the ultrasonic wave, and the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com