Method for producing titanium polymer resin anti-dirty corrosion-resistant oil pipe for oil field

A technology of titanium polymer and tubing, which is applied in the field of preparing oil tubing for oilfields, to achieve the effects of high adhesion, strong penetration resistance, and high boiling water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A 73×5.51mm oil pipe with a length of 9.7m is selected. After sandblasting and derusting, the outer surface of the oil pipe is sprayed with titanium polymer anti-scaling and anti-corrosion coating with compressed air; the inner wall of the oil pipe is sprayed with high-pressure airless titanium polymer anti-scaling and anti-corrosion coating. The coating ratio is: Component A: Component B=100:15 (weight ratio). The titanium polymer anti-corrosion coating used on the inner wall is cured using a curing tempering furnace. The inner and outer surfaces are cured at the same time, curing conditions: curing temperature 60°C, curing time 60min, furnace power 200kw, the oil pipe advances while rotating in the quenching and tempering curing furnace, and the oil pipe rotates at a speed of 50r / min.

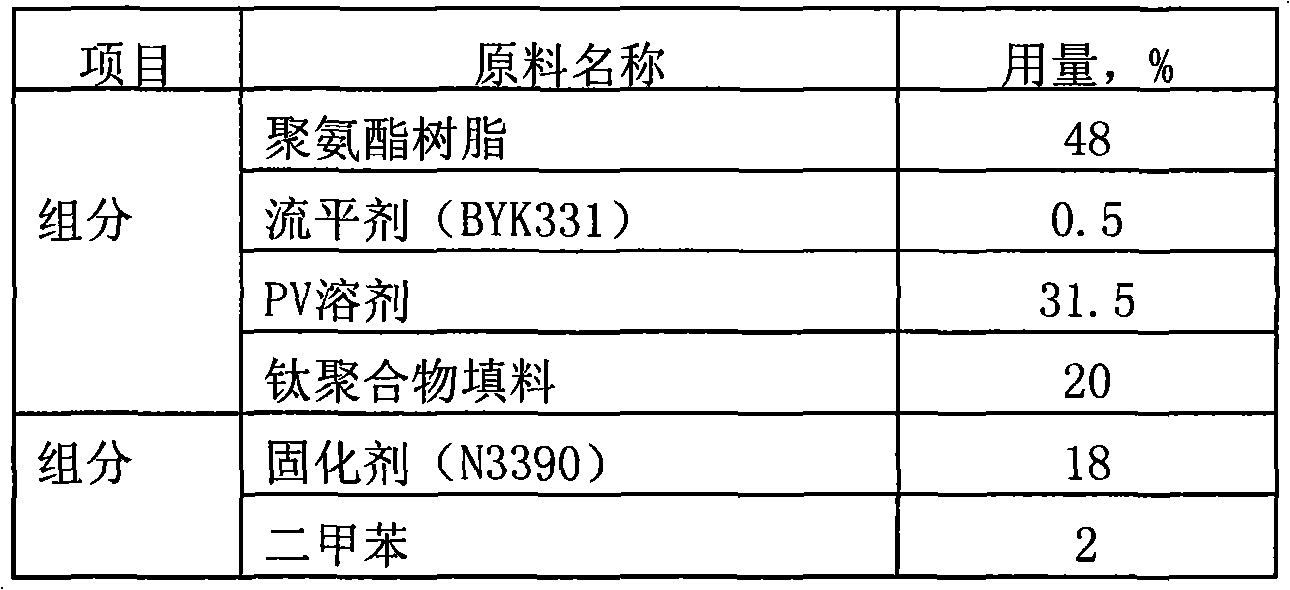

[0017] The titanium polymer antifouling and anticorrosion coating comprises the following components by weight percentage:

[0018]

[0019] Among them, epoxy resin E-03 type, epox...

Embodiment 2

[0022] The titanium polymer antifouling and anticorrosion coating comprises the following components by weight percentage:

[0023] raw material name

Dosage, %

Epoxy resin (E-03)

55

Butanol Etherified Phenolic Resin

13

epoxy ester

2

10

12

Titanium polymer filler

8

[0024] Manufacturer of butanol etherified phenolic resin and epoxy ester: Wuxi Paint Factory.

[0025] Curing conditions: normal temperature for 24 hours; other conditions are the same as in Example 1.

[0026] The tubing has been used in Well 2-Xing 1-P4 in the Xingerzhong block of Daqing for more than a year with anti-scaling and anti-corrosion tubing, and there has been no pump jamming due to scaling.

Embodiment 3

[0028] The titanium polymer antifouling and anticorrosion coating comprises the following components by weight percentage:

[0029]

[0030] Curing at room temperature for 24 hours; other conditions are the same as in Example 1.

[0031] In the field test of the 1-6-P34 ASP flooding well in North Daqing, the well basically needs to be pickled and cleaned every 20 days, otherwise the phenomenon of scaling and shrinking of the tubing and scale falling off and jamming the pump will occur. , affecting normal production, it can be seen that the scale phenomenon is relatively serious. During the use of the oil pipe obtained in this embodiment, the scale cleaning interval reached 60 days, which was 40 days longer than before, which was twice as long. The scale is loose and can be wiped off by hand without affecting oil field production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com