Method for preparing SiC/Ti3SiC2 with substitution reaction hot press in situ

An in-situ and reaction technology is applied in the field of preparing silicon carbide SiC reinforced silicon carbide titanium Ti3SiC2 ceramic matrix composite materials to achieve the effect of inhibiting the formation of TiC, fine particle size, and uniform microstructure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) According to the molar ratio of Si:TiC:Al=2:3:0.2, weigh 11.65 grams of Si powder, 37.23 grams of TiC powder, and 1.12 grams of Al powder;

[0027] 2) Put the above-mentioned ingredients and agate balls into the ball mill tank, and place them on the ball mill for mixing for 10 hours;

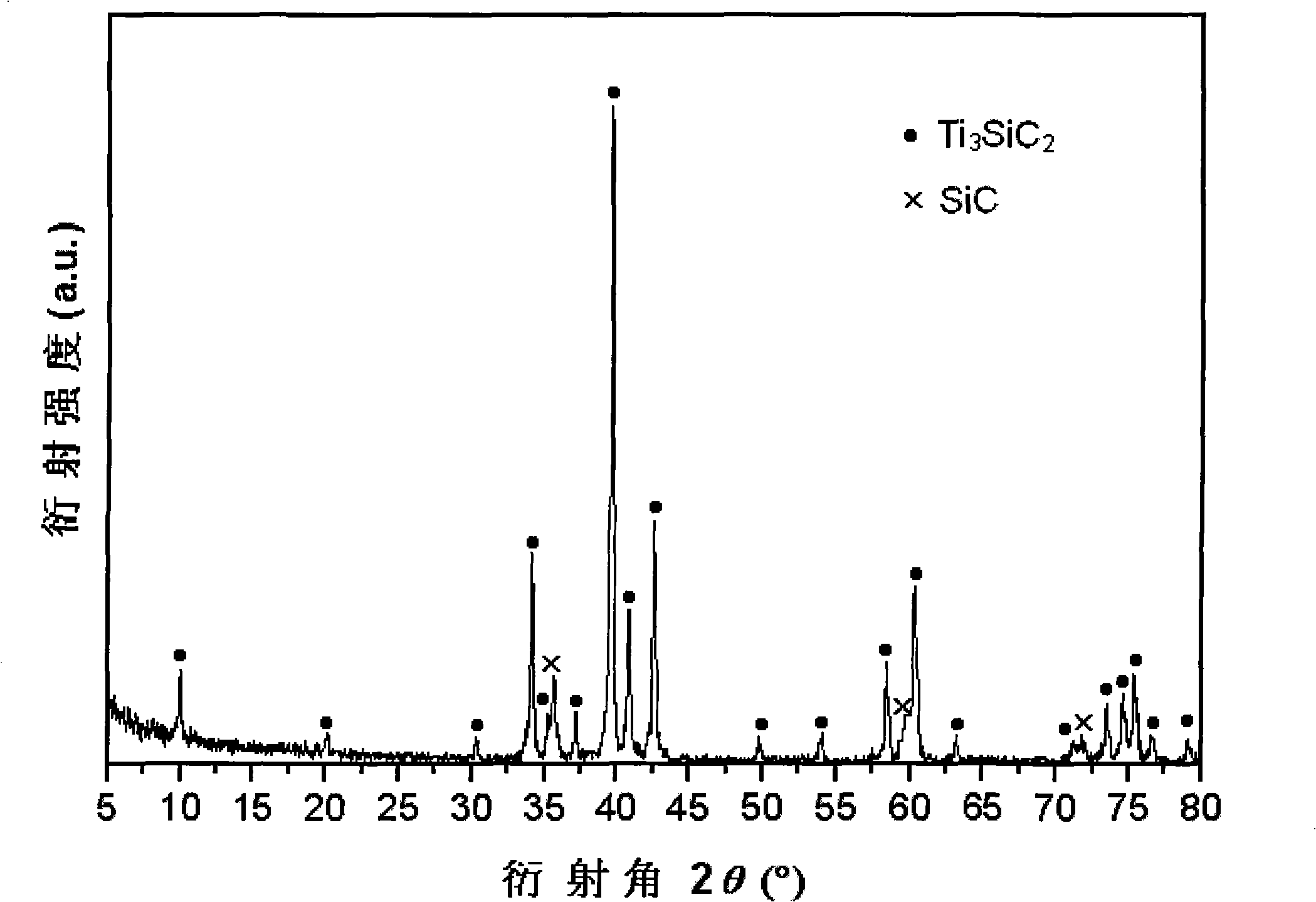

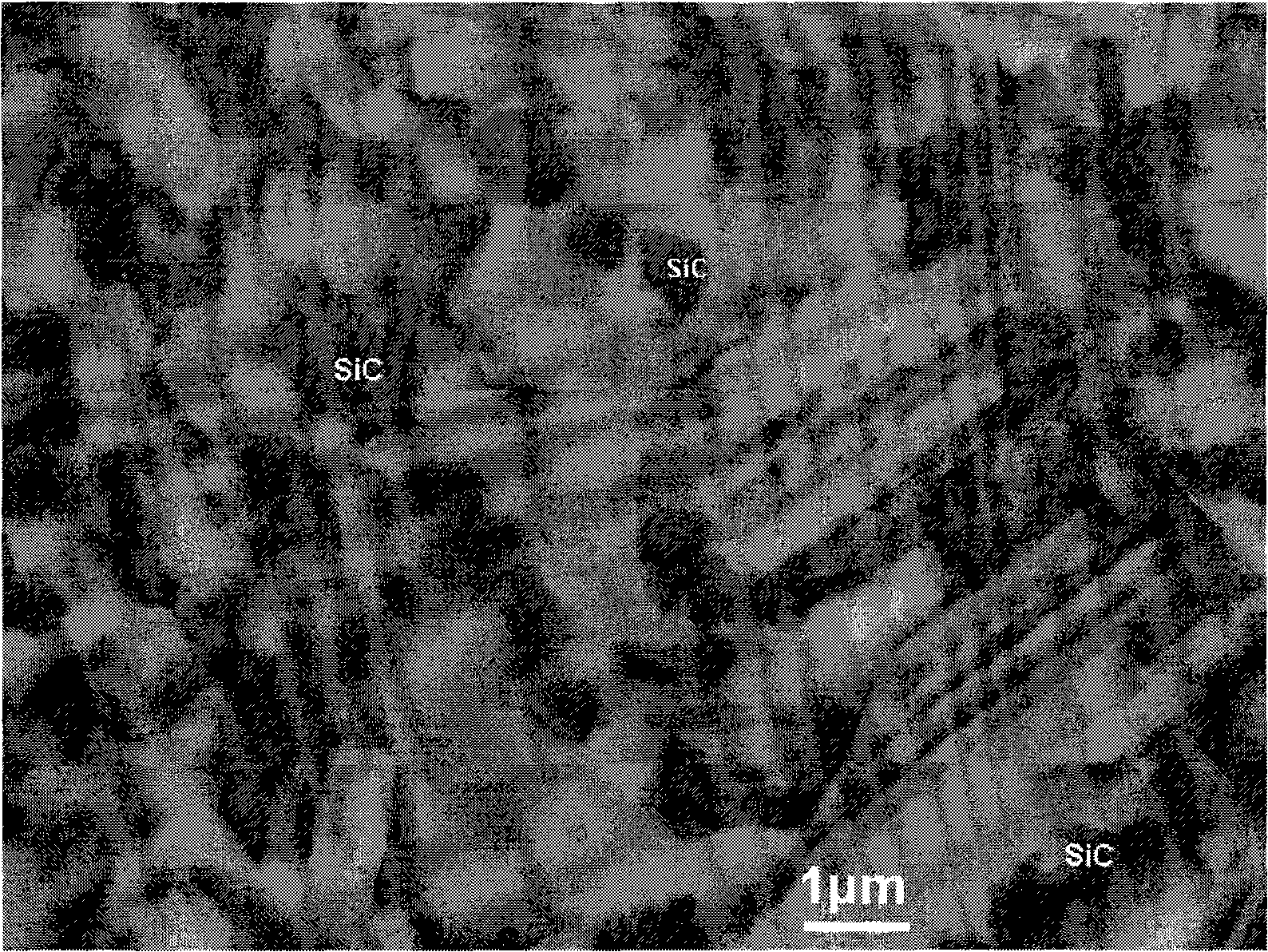

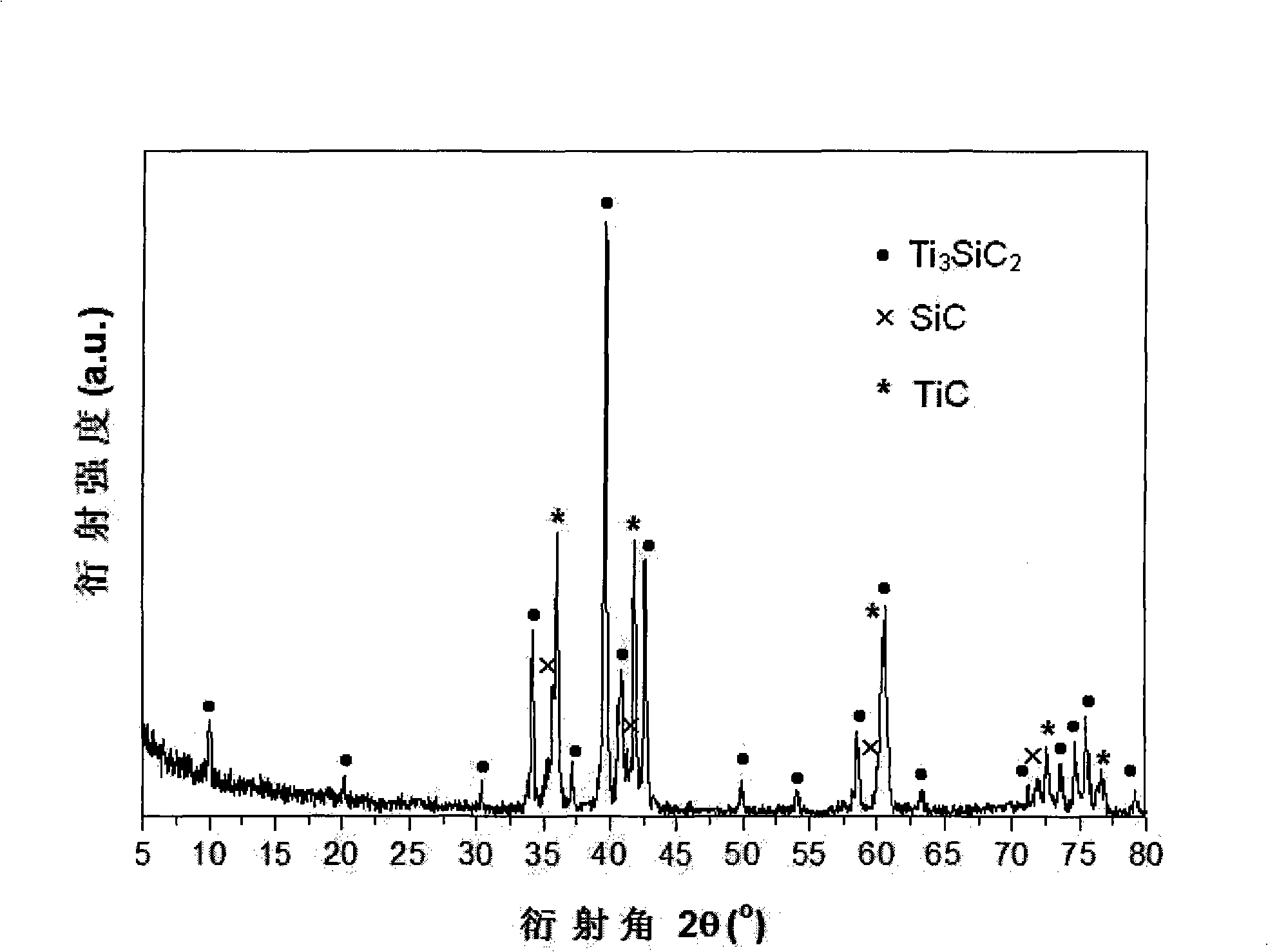

[0028] 3) Put the uniformly mixed ingredients into the graphite mold, place the graphite mold in a hot-press furnace, and raise the furnace temperature to 1350°C at a heating rate of 30°C / min under an argon protective atmosphere, and at the same time heat the Apply a pressure of 40MPa to the powder and keep it warm for 2 hours. That is, SiC / Ti is produced 3 SiC 2Bulk composites with a SiC content of 10% by weight, Ti 3 SiC 2 The content is 90%. The bending strength of the composite material is ≥500MPa, and the fracture toughness is ≥6MPa m 1 / 2 . The XRD pattern of the material is as figure 1 shown. It can be seen from the figure that only SiC and Ti 3 SiC 2 Diffraction peaks...

Embodiment 2

[0030] 1) According to the molar ratio of Si:TiC:Al=2:3:0.2, weigh 11.65 grams of Si powder, 37.23 grams of TiC powder, and 1.12 grams of Al powder;

[0031] 2) Put the above-mentioned ingredients and agate balls into a ball mill jar, and place them on the ball mill for mixing for 10 hours;

[0032] 3) Put the uniformly mixed ingredients into the graphite mold, place the graphite mold in a hot-press furnace, and raise the temperature of the furnace to 1450°C at a heating rate of 30°C / min under an argon protective atmosphere. Apply a pressure of 40MPa to the powder and keep it warm for 4 hours. That is, SiC / Ti is produced 3 SiC 2 Bulk composites with a SiC content of 10% by weight, Ti 3 SiC 2 The content is 90%. The bending strength of the composite material is ≥500MPa, and the fracture toughness is ≥6MPa m 1 / 2 . Its XRD result and microstructure are identical with embodiment one.

Embodiment 3

[0034] 1) According to the molar ratio of Si:TiC:Al=2:3:0.4, weigh 11.39 grams of Si powder, 36.41 grams of TiC powder, and 2.2 grams of Al powder;

[0035] 2) Put the above-mentioned ingredients and agate balls into a ball mill jar, and place them on the ball mill for mixing for 10 hours;

[0036] 3) Put the uniformly mixed ingredients into the graphite mold, place the graphite mold in a hot-press furnace, and raise the furnace temperature to 1500°C at a heating rate of 40°C / min under an argon protective atmosphere, and at the same time heat the Apply a pressure of 30MPa to the powder and keep it warm for 1 hour. That is, SiC / Ti is produced 3 SiC 2 Bulk composites with a SiC content of 10% by weight, Ti 3 SiC 2 The content is 90%. The bending strength of the composite material is ≥500MPa, and the fracture toughness is ≥6MPa m 1 / 2 . Its XRD result and microstructure are identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com