Micro-pore mullite lightweight aggregate and preparation method thereof

A lightweight aggregate and mullite technology, applied in the field of refractory materials, can solve problems such as low compressive strength and refractoriness, uneven distribution of pores, and high volume density, and achieve high refractoriness, low cost, and high volume density. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

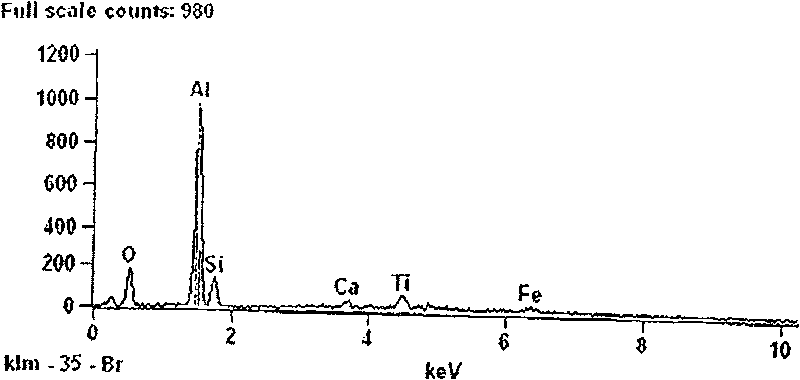

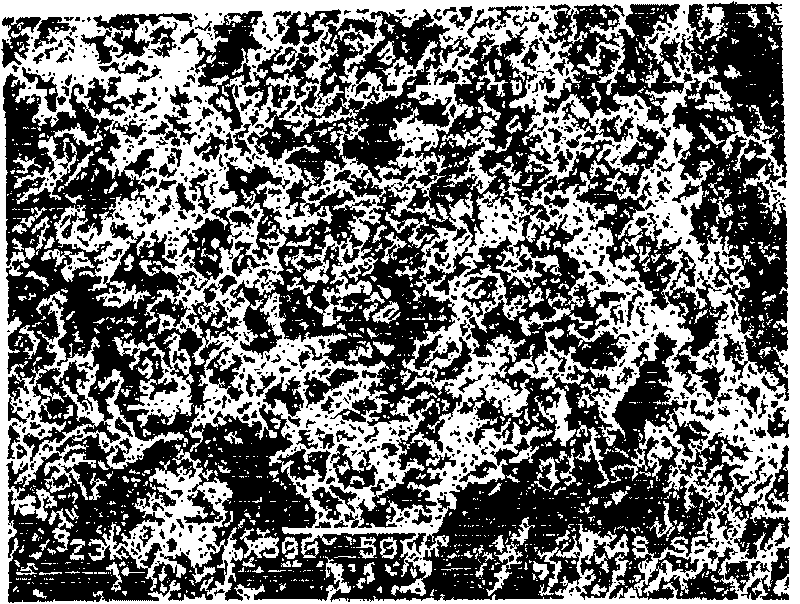

Image

Examples

Embodiment 1

[0025] Microporous mullite lightweight aggregate, made of the following raw materials in weight percentage: bauxite raw meal 35%, coal gangue 20%, sawdust 13%, petroleum coke 32%, Fe in the above petroleum coke 2 o 3 Content is 1%, Al 2 o 3 The content is 8%, and the preparation method includes the following steps: (1) respectively crushing bauxite raw meal, coal gangue, sawdust and petroleum coke, and mixing them uniformly; (2) adding water accounting for 80% of the total weight of the above raw materials, and performing wet Grinding; (3) sieve filtration to obtain undersize with a mesh number of 400 and a water content of 15%; (4) molding with a molding pressure of 6 MPa; (5) drying at a temperature of 180° C. for 65 hours; (6) Calcining at 1400°C for 9 days; (7) Crushing; (8) Sieving to obtain mullite lightweight aggregate.

Embodiment 2

[0027] Microporous mullite lightweight aggregate, made of the following raw materials in weight percentage: bauxite raw meal 40%, coal gangue 14%, sawdust 4%, petroleum coke 42%, Fe in the above petroleum coke 2 o 3 Content is 2%, Al 2 o 3 The content is 10%, and the preparation method includes the following steps: (1) respectively crushing bauxite raw meal, coal gangue, sawdust and petroleum coke, and mixing them uniformly; (2) adding water accounting for 85% of the total weight of the above raw materials, and performing Grinding; (3) sieve filtration to obtain undersize with a mesh number of 450 and a water content of 20%; (4) molding with a molding pressure of 8 MPa; (5) drying at a temperature of 200° C. for 75 hours; (6) Calcining at 1450°C for 10 days; (7) Crushing; (8) Sieving to obtain mullite lightweight aggregate.

Embodiment 3

[0029] Microporous mullite lightweight aggregate, made of the following raw materials in weight percentage: bauxite raw meal 38%, coal gangue 16%, sawdust 10%, petroleum coke 36%, Fe in the above petroleum coke 2 o 3 Content is 2%, Al 2 o 3The content is 9%, and the preparation method includes the following steps: (1) respectively crushing bauxite raw meal, coal gangue, sawdust and petroleum coke, and mixing them uniformly; (2) adding water accounting for 82% of the total weight of the above-mentioned raw materials for wet Grinding; (3) sieve filtration to obtain the mesh undersize of 420 meshes, with a water content of 18%; (4) molding, the molding pressure is 7MPa; (5) drying, the temperature is 195°C, and the time is 70h; (6) Calcining at 1425°C for 9 days; (7) Crushing; (8) Sieving to obtain mullite lightweight aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com