Application of femtosecond laser in pure titanium implantation material surface treatment

An implant material, femtosecond laser technology, used in bone implants, laser welding equipment, and protective layers, etc., can solve the problems of easy shedding of the bioactive layer, inability to obtain surface patterns, and difficulty in roughness. Achieve the effect of improving biocompatibility, tight bonding and thin processing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to put 10×10×3mm 3 The large and small blocks of pure titanium implant material are polished step by step with 400-800 water sandpaper, then ultrasonically cleaned in deionized water, sealed and dried at room temperature, and then placed on the three-axis mobile sample stage to adjust the pure titanium implant material. surface to keep it level;

[0028] In the second step, in the air, the femtosecond laser pulse is vertically incident directly above the bulk pure titanium implant material processed in the first step, using a Nd:YAG laser and assisted focusing through a 10x objective lens, the femtosecond laser pulse Focus on the surface of the bulk pure titanium implant material to form a spot with a radius of 5 μm;

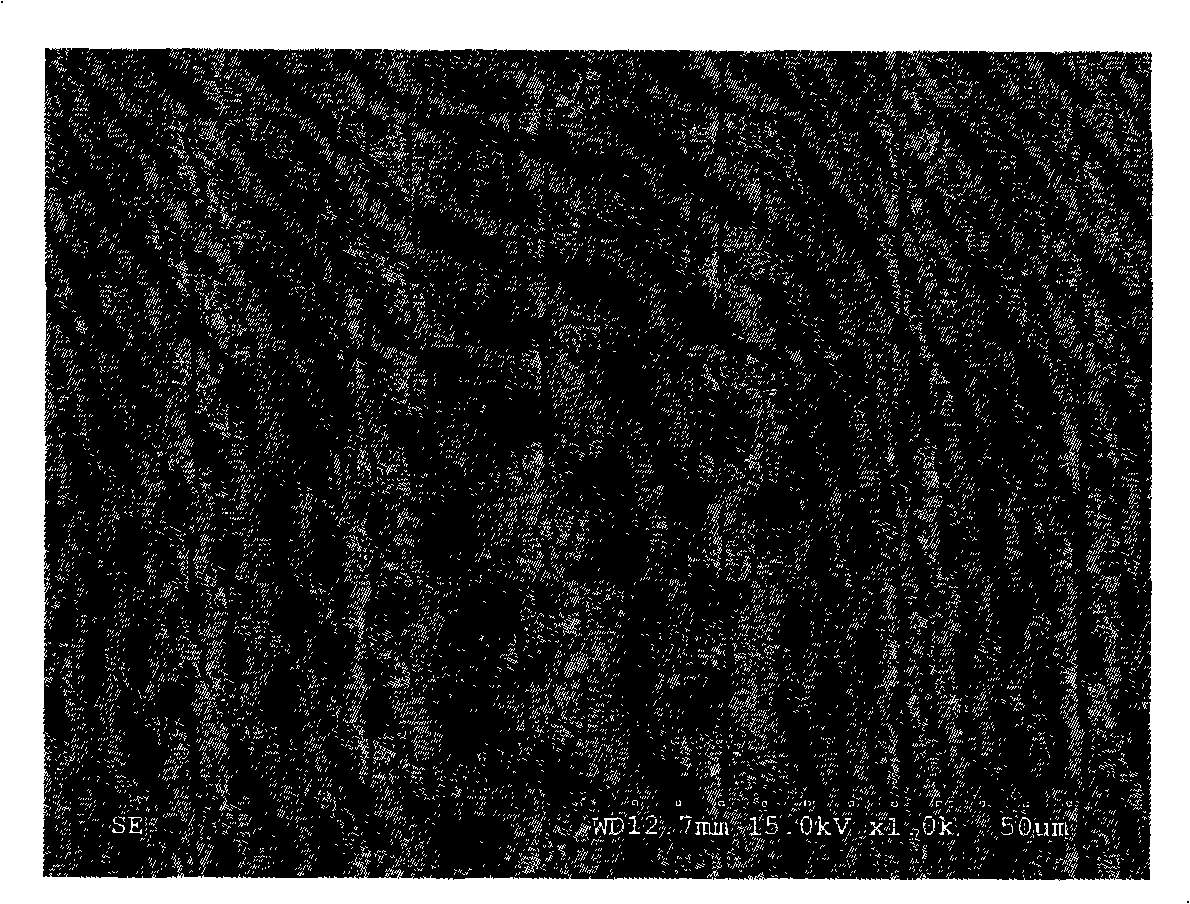

[0029] The third step is to set the femtosecond laser processing parameters as follows: pulse repetition frequency 1 kHz; single pulse energy 5 microjoules; pulse width 50 femtoseconds; pulse center wavelength 800 nanometers; laser proc...

Embodiment 2

[0033] The first step, with embodiment 1;

[0034] Second step, with embodiment 1;

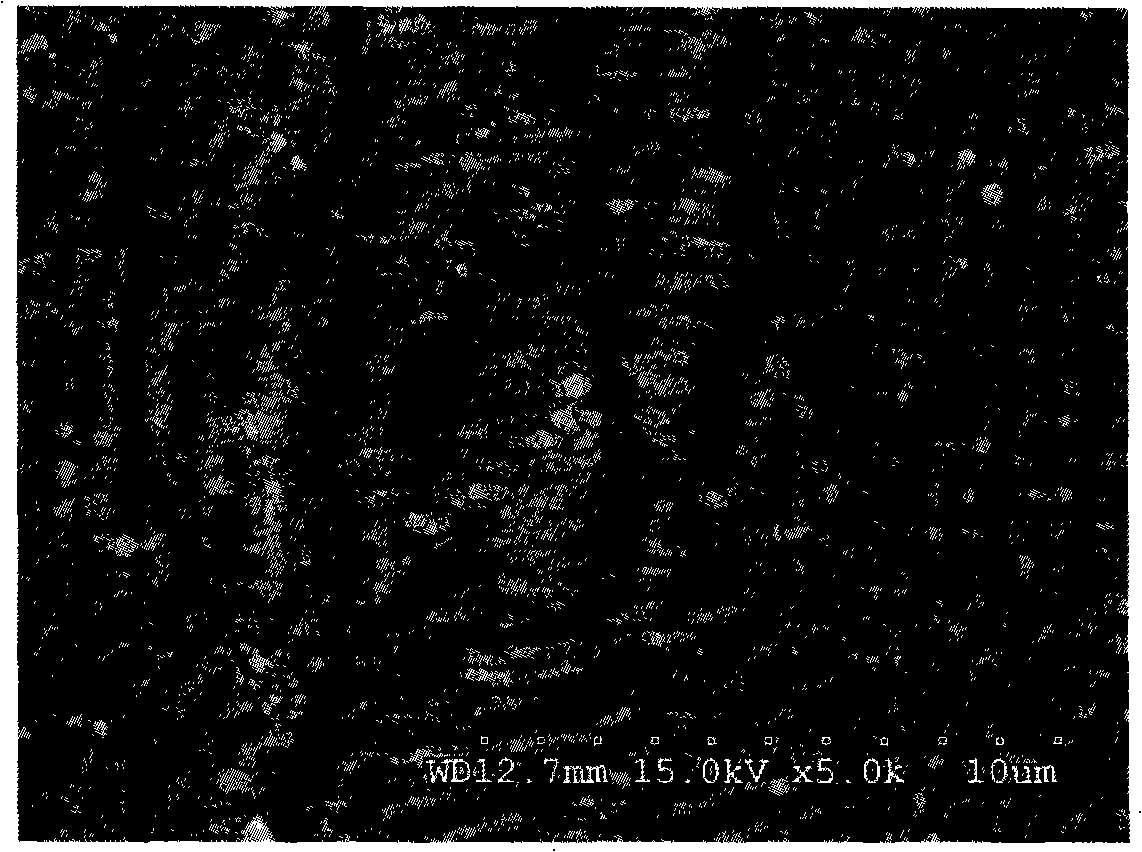

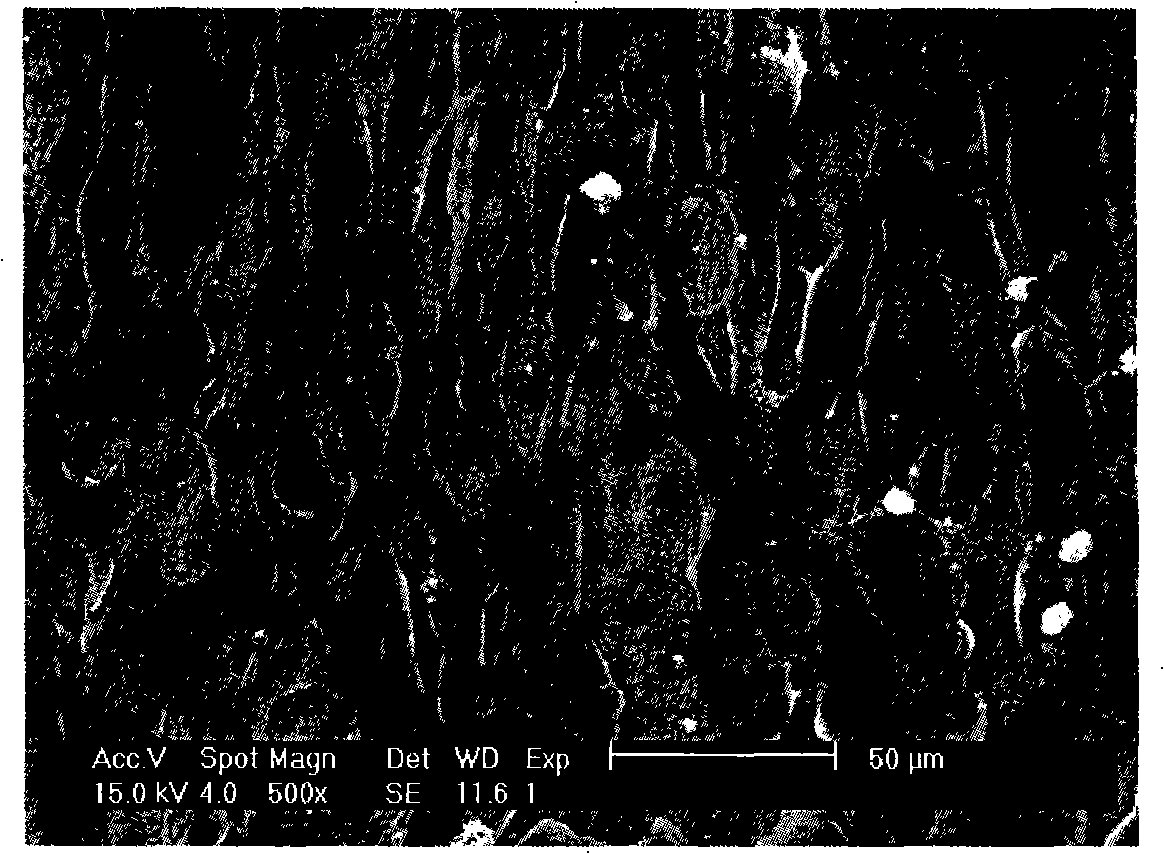

[0035] The third step is to set the femtosecond laser processing parameters as follows: pulse repetition frequency 1 kHz; single pulse energy 150 microjoules; pulse width 50 femtoseconds; pulse center wavelength 800 nanometers; laser processing line spacing 100 microns, laser scanning speed 0.5 mm / second, adjust the laser polarization direction parallel to the laser scanning direction, scan the entire surface of the block pure titanium implant material with the femtosecond laser, thus forming uniform stripes, holes and holes on the surface of the pure titanium implant material A regular pattern of groove configuration combination, that is, a titanium-based biomedical material with uniform roughness and an oxide layer formed on the titanium surface.

[0036] Mouse osteoblasts were cultured on the obtained oxidized layer to verify their biological activity. The cells and culture methods used we...

Embodiment 3

[0039] The other steps are the same as in Example 2, except that the single laser pulse energy is set to 100 microjoules, the laser scanning speed is set to 0.8 mm / s, and the laser processing line spacing is set to 100 microns. Result is with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com