High phosphorous poisoning resistant catalysts for treating automobile exhaust

一种催化剂、耐受性的技术,应用在物理/化学过程催化剂、催化剂活化/制备、排气处理等方向,能够解决被污染等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

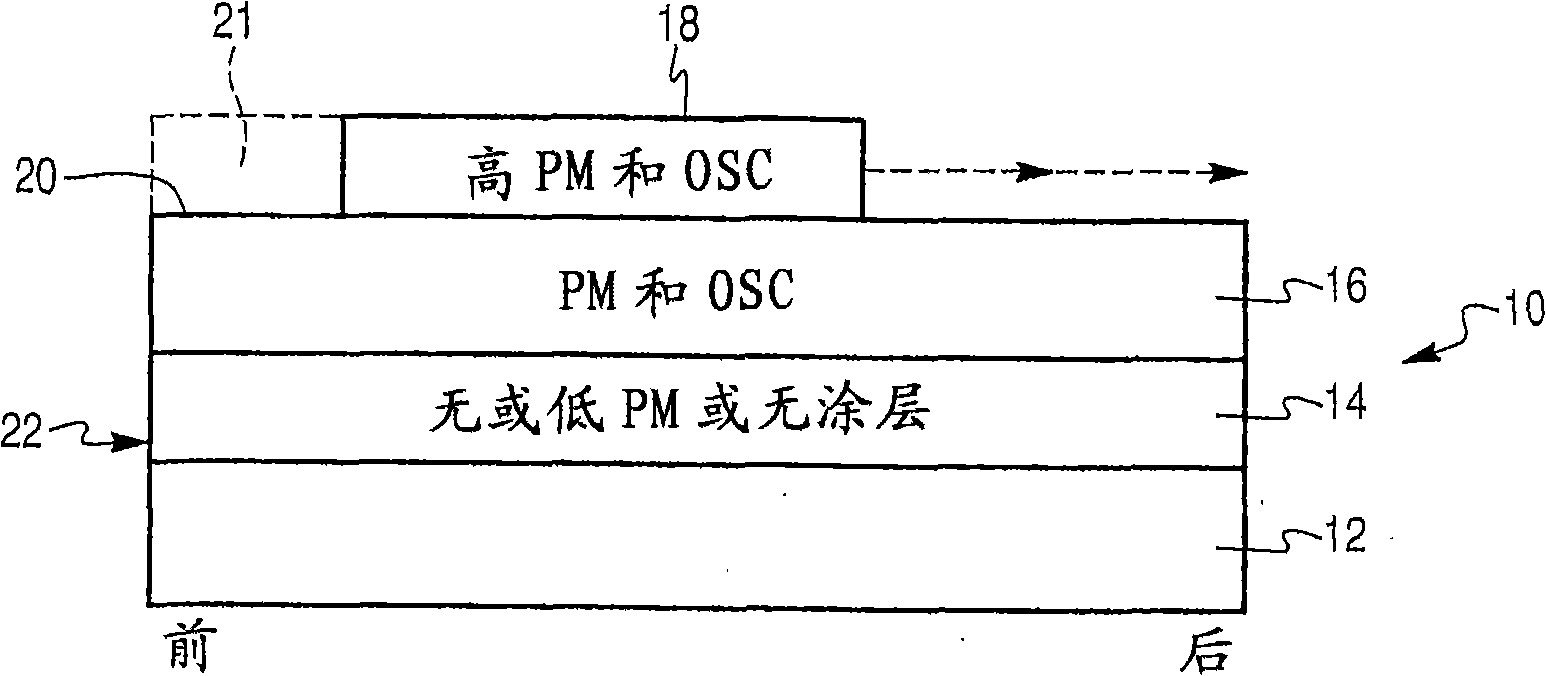

[0047] In this embodiment, form as figure 1 Catalysts shown.

[0048] The first poison trap layer is formed on the ceramic honeycomb. 92.8 parts of gamma-alumina were combined with 7.3 parts of alumina-based binder, 2.9 parts of zirconia-based binder, 562 parts of deionized water, and 70 parts of 90% concentrated acetic acid prior to milling to produce 40% solids Slurry. Milling was performed until the particle size distribution showed that 90% of the particles became smaller than 10 microns.

[0049] After milling, the slurry was coated on a ceramic honeycomb with 900 cells per square foot (cpsi) and 2.5 mil wall thickness. Coating was performed by immersing the honeycomb substrate in the slurry, dripping the slurry dry, and then blowing off the excess slurry with compressed air. The coated honeycomb was dried at 110°C for 4 hours and calcined at 550°C for 2 hours.

[0050] The intermediate layer is then formed through the following steps. In a planetary mixer, 0.9 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com