Micrometre level docosahexaenoic acid emulsion and preparation thereof

A technology of carbhexaenoic acid emulsion and docosahexaenoic acid, which is applied in the directions of emulsion delivery, food preparation, pharmaceutical formula, etc., can solve the problem of increasing production cost, difficulty in infant formula food, inability to withstand high temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

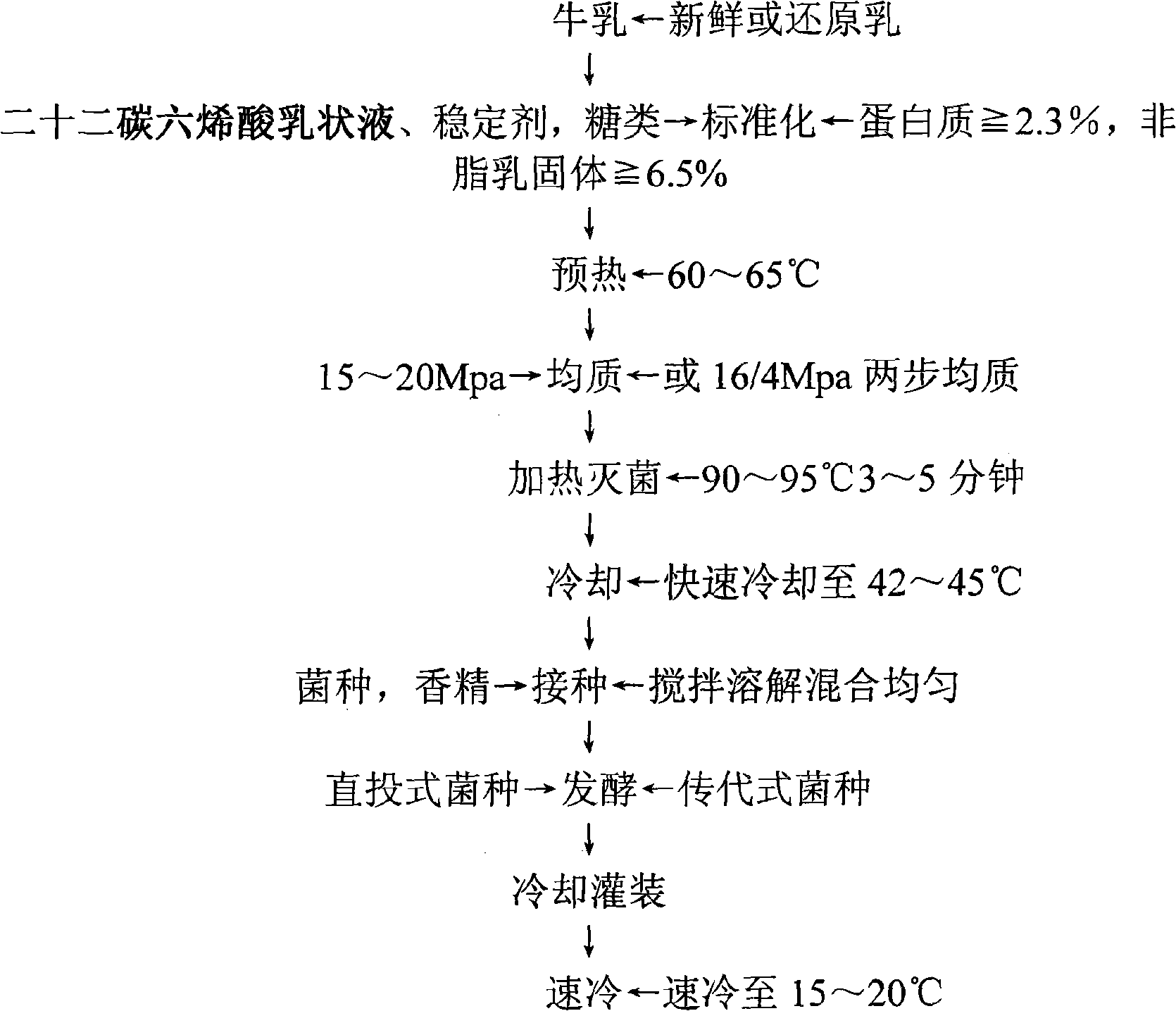

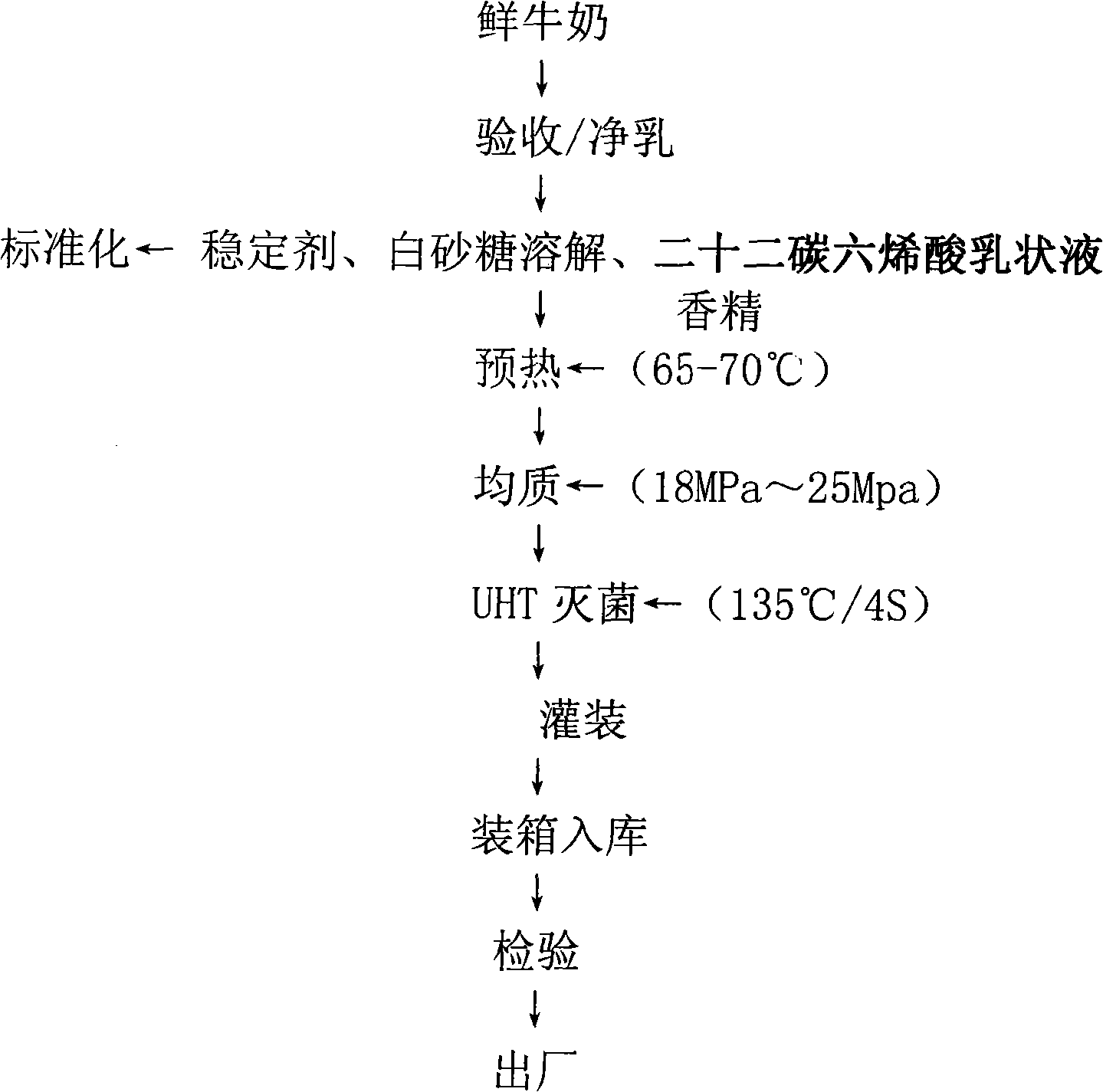

[0045] The preparation method of docosahexaenoic acid emulsion of the present invention, the steps are:

[0046] 1) Oil phase part: add docosahexaenoic acid oil with a concentration higher than 30% into the oil phase emulsifier, coating agent, and antioxidant according to the above weight ratio, and heat the oil bath to 40-70°C to dissolve it , to make oil phase product A;

[0047] 2) Water phase part: Add water phase emulsifier, stabilizer and dispersant into water according to the above weight ratio, fully stir, heat to 60-90°C, keep for 20-60min, and make water phase product B;

[0048] 3) After the temperature of the water phase product B drops to 40-70°C, slowly add A to B, perform primary emulsification with a high-speed shearing machine, and obtain product C;

[0049] 4) pressure homogenize product C to obtain product D;

[0050] 5) After sterilizing and cooling the product D, the product E is obtained, which is the docosahexaenoic acid emulsion.

[0051] In the prep...

Embodiment 1

[0055] Embodiment 1 contains the preparation of DHA50g / kg emulsion:

[0056] Take by weighing 145 grams of mixed grease with 35% docosahexaenoic acid content, 0.5 grams of antioxidants (comprising 0.2 grams of natural vitamin E, 0.1 grams of sodium ascorbate, 0.2 grams of tea polyphenols), 10 grams of coating agents (comprising sunflower 5 grams of seed oil, 5 grams of palm oil), 14 grams of oil phase emulsifier (including 6 grams of lecithin, 8 grams of Span 20), they are mixed while heating, and when the temperature rises to 55 ° C, they are immediately transferred to water equivalent Medium (water phase temperature 75°C chemical material 40min, then cooled to 55°C), the water phase contains 8 grams of emulsifier in the water phase (including 3 grams of citrate fatty acid glycerides, 5 grams of Tween 65), 10 grams of dispersant (containing 10 grams of sucrose) and 75 grams of thickening stabilizer (including 70 grams of modified starch and 5 grams of sodium alginate), supple...

Embodiment 2

[0057] Embodiment 2 contains the preparation method of DHA50g / kg emulsion:

[0058] Weigh 145 grams of mixed oil with 35% docosahexaenoic acid content, 10.25 grams of antioxidants (comprising 4 grams of natural vitamin E, 2.25 grams of sodium ascorbate, 4 grams of tea polyphenols), 30 grams of coating agent (comprising sunflower oil 15 grams of palm oil, 15 grams of palm oil), 72 grams of oil phase emulsifier (including 30 grams of lecithin, 42 grams of Span 20), they are mixed while heating, and when the temperature rises to 55 ° C, they are immediately transferred to the water equivalent ( Water phase temperature 75 ℃ chemical material 40min, then cooled to 55 ℃), the water phase contains 29 grams of water phase emulsifier (comprising 10.8 grams of citrate fatty acid glyceride, 18.2 grams of Tween 65), 55 grams of dispersant (comprising sucrose 55 gram) and 212.5 grams of thickening stabilizer (comprising 195 grams of modified starch, 17.5 grams of sodium alginate), suppleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com