Method for preparing bio-diesel by immobilized lipase-alcohol perselective membrane bioreactor

A technology for immobilizing lipase and bioreactor, which is applied in the directions of enzyme production/bioreactor, biochemical equipment and method, liquid production bioreactor, etc. The effect of simplifying the process and avoiding the inhibition of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

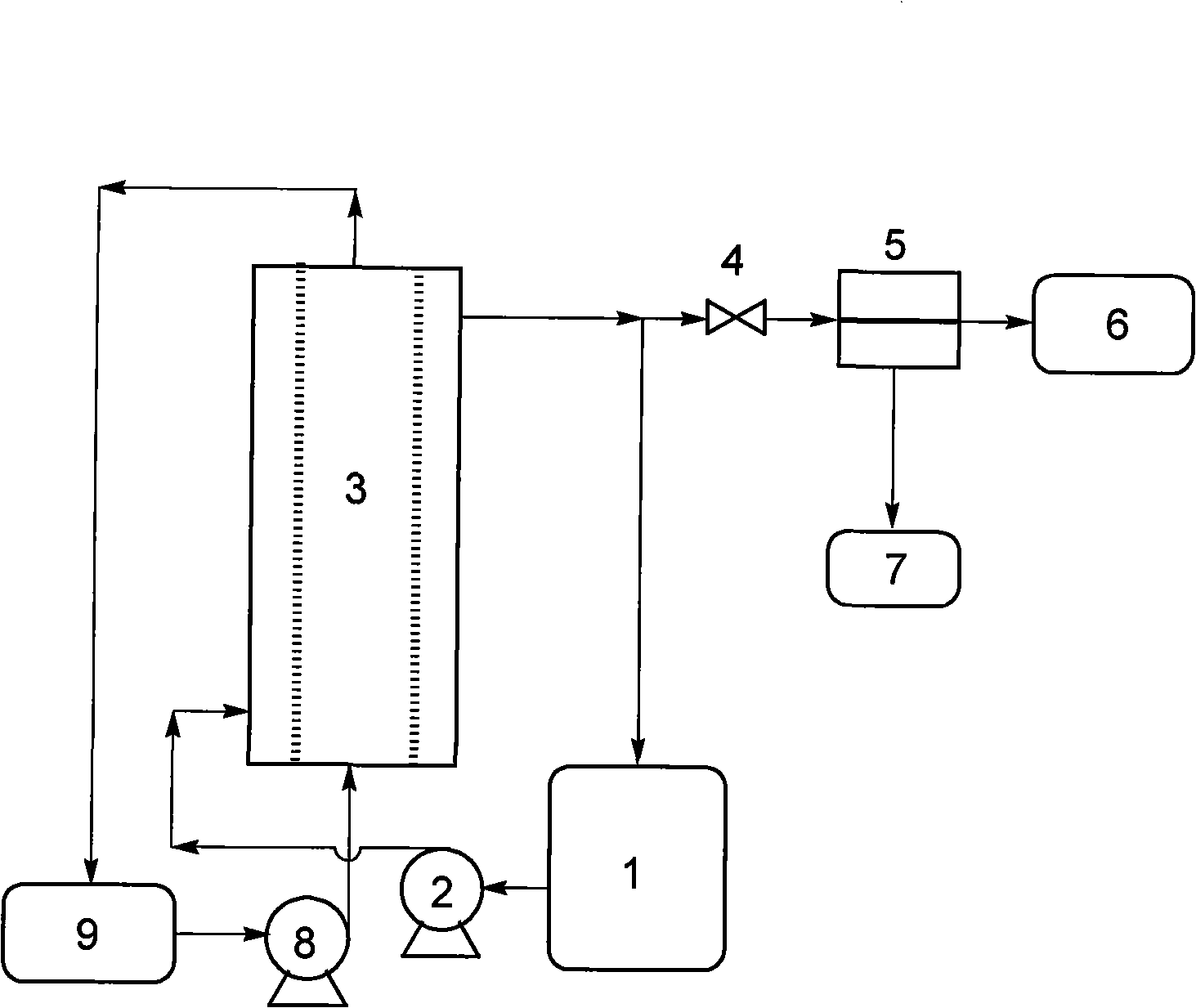

[0018] The lipase derived from Candida antarctica was immobilized on the surface of polydimethylsiloxane hollow fiber membrane by physical adsorption to make a membrane module, which was connected to an enzyme-membrane bioreactor. Inject 5L of fish oil into the grease storage tank 1, and go through the membrane module 3 shell side through the pump 2, with a flow rate of 4L / h; the methanol in the low-carbon alcohol storage tank 9 goes through the membrane module 3 tube side through the pump 8, with a flow rate of 20L / h. The yield of biodiesel is about 95% after 2 hours of circulation.

Embodiment 2

[0020] Lipase derived from Rhizomucor miehei was immobilized on the surface of polytrimethylsilapropyne hollow fiber membrane by physical adsorption to make a membrane module, which was connected to an enzyme-membrane bioreactor. Inject 5L of lard into the grease storage tank 1, and go through the membrane module 3 shell side through the pump 2, with a flow rate of 4L / h; the methanol in the low-carbon alcohol storage tank 9 is passed through the membrane module 3 tube side through the pump 8, with a flow rate of 20L / h . The yield of biodiesel is about 96% after 4h circulation.

Embodiment 3

[0022] Lipase derived from Thermomyces lanuginosus was immobilized on the surface of chitosan hollow fiber membrane by physical adsorption to make a membrane module, which was connected to an enzyme-membrane bioreactor. Inject 5L of castor oil into the grease storage tank 1, and go through the pump 2 to the shell side of the membrane module 3 at a flow rate of 5L / h; the ethanol in the low-carbon alcohol storage tank 9 is fed to the membrane module 3 tube side by the pump 7 at a flow rate of 100L / h . The yield of biodiesel is about 100% after circulation for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com