Method for preparing titanium oxide nano-wire array

A nanowire array, titanium dioxide technology, applied in titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of uneven template filling, insufficient driving force, low filling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

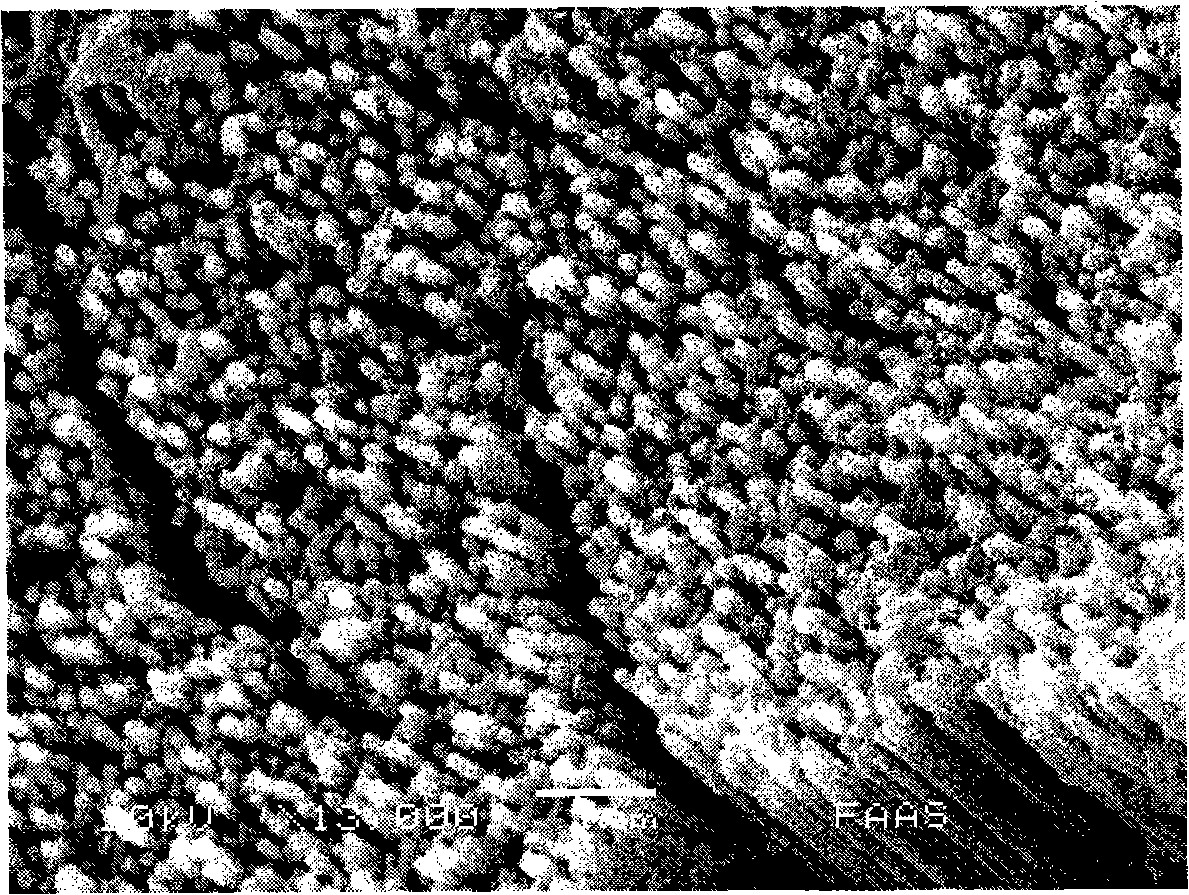

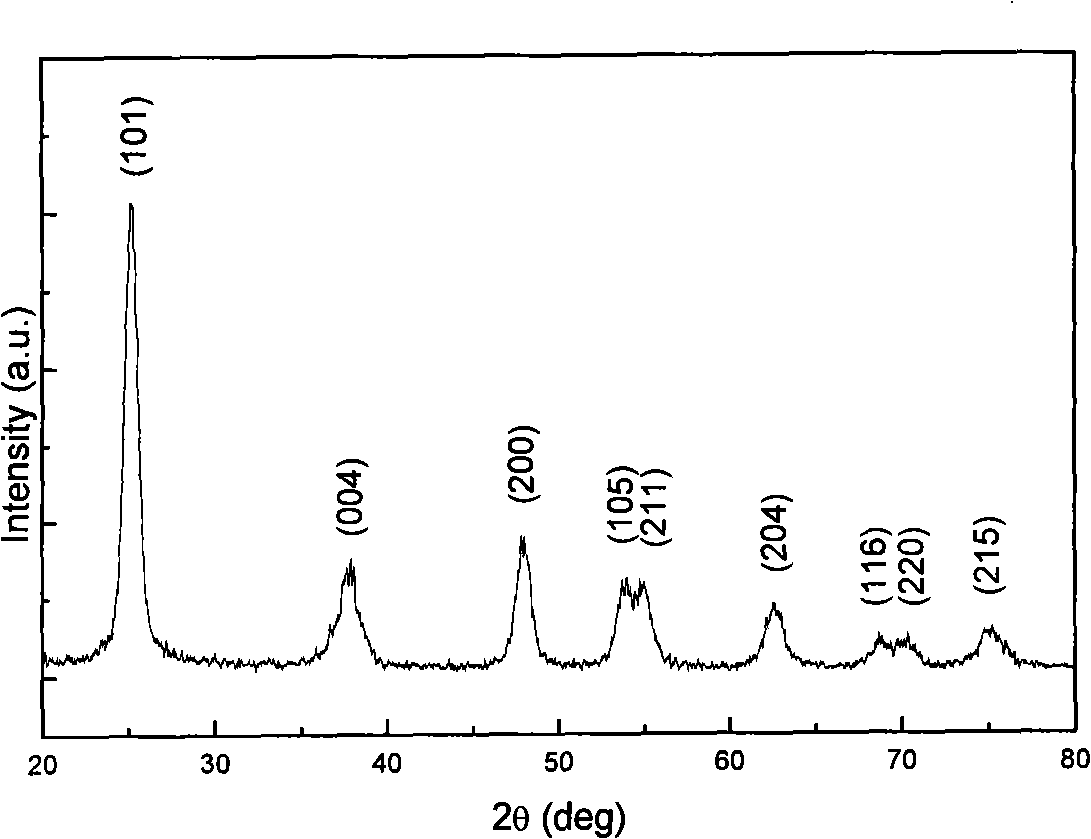

Image

Examples

Embodiment 1

[0026] The first step is to take a high-purity circular aluminum sheet with a diameter of 22mm and a purity of 99.99%, and perform surface pretreatment on it: put the high-purity aluminum sheet in acetone for ultrasonic cleaning, and after cleaning and drying, place the aluminum sheet at 400°C in a vacuum Anneal for 4 hours, then carry out electrochemical polishing in a mixture of absolute ethanol and perchloric acid with a volume ratio of 9:1, and the polishing current is 300mA / cm 2 , the polishing was carried out in an ice-water bath, and the polishing time was 90 seconds;

[0027] In the second step, place the aluminum sheet treated in the first step in an oxalic acid solution with a concentration of 0.3mol / l for the first anodic oxidation. The anode is the aluminum sheet, the cathode is a lead electrode, and the solution temperature is 10°C. , the voltage used for anodizing is 40V, and the time is 6 hours;

[0028] The third step is to immerse the aluminum sheet treated i...

Embodiment 2

[0035] The first step is to take a high-purity circular aluminum sheet with a diameter of 22mm and a purity of 99.99%, and perform surface pretreatment on it: put the high-purity aluminum sheet in acetone for ultrasonic cleaning, and after cleaning and drying, place the aluminum sheet at 400°C in a vacuum Anneal for 4 hours, then carry out electrochemical polishing in a mixture of absolute ethanol and perchloric acid with a volume ratio of 9:1, and the polishing current is 300mA / cm 2 , the polishing was carried out in an ice-water bath, and the polishing time was 90 seconds;

[0036] In the second step, place the aluminum sheet treated in the first step in an oxalic acid solution with a concentration of 0.3mol / l for the first anodic oxidation. The anode is the aluminum sheet, the cathode is a lead electrode, and the solution temperature is 10°C. , the voltage used for anodizing is 40V, and the time is 6 hours;

[0037] The third step is to immerse the aluminum sheet treated i...

Embodiment 3

[0044] The first step is to take a high-purity circular aluminum sheet with a diameter of 22mm and a purity of 99.99%, and perform surface pretreatment on it: put the high-purity aluminum sheet in acetone for ultrasonic cleaning, and after cleaning and drying, place the aluminum sheet at 400°C in a vacuum Anneal for 4 hours, then carry out electrochemical polishing in a mixture of absolute ethanol and perchloric acid with a volume ratio of 9:1, and the polishing current is 300mA / cm 2 , the polishing was carried out in an ice-water bath, and the polishing time was 90 seconds;

[0045] In the second step, place the aluminum sheet treated in the first step in an oxalic acid solution with a concentration of 0.3mol / l for the first anodic oxidation. The anode is the aluminum sheet, the cathode is a lead electrode, and the solution temperature is 10°C. , the voltage used for anodizing is 40V, and the time is 6 hours;

[0046] The third step is to immerse the aluminum sheet treated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com