Controllable preparation method of orthorhombic-phase rhombohedral-phase sodium niobate having high Curie point

A high Curie point, phase sodium niobate technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of high cost and complicated process, and achieve low preparation cost, high purity and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

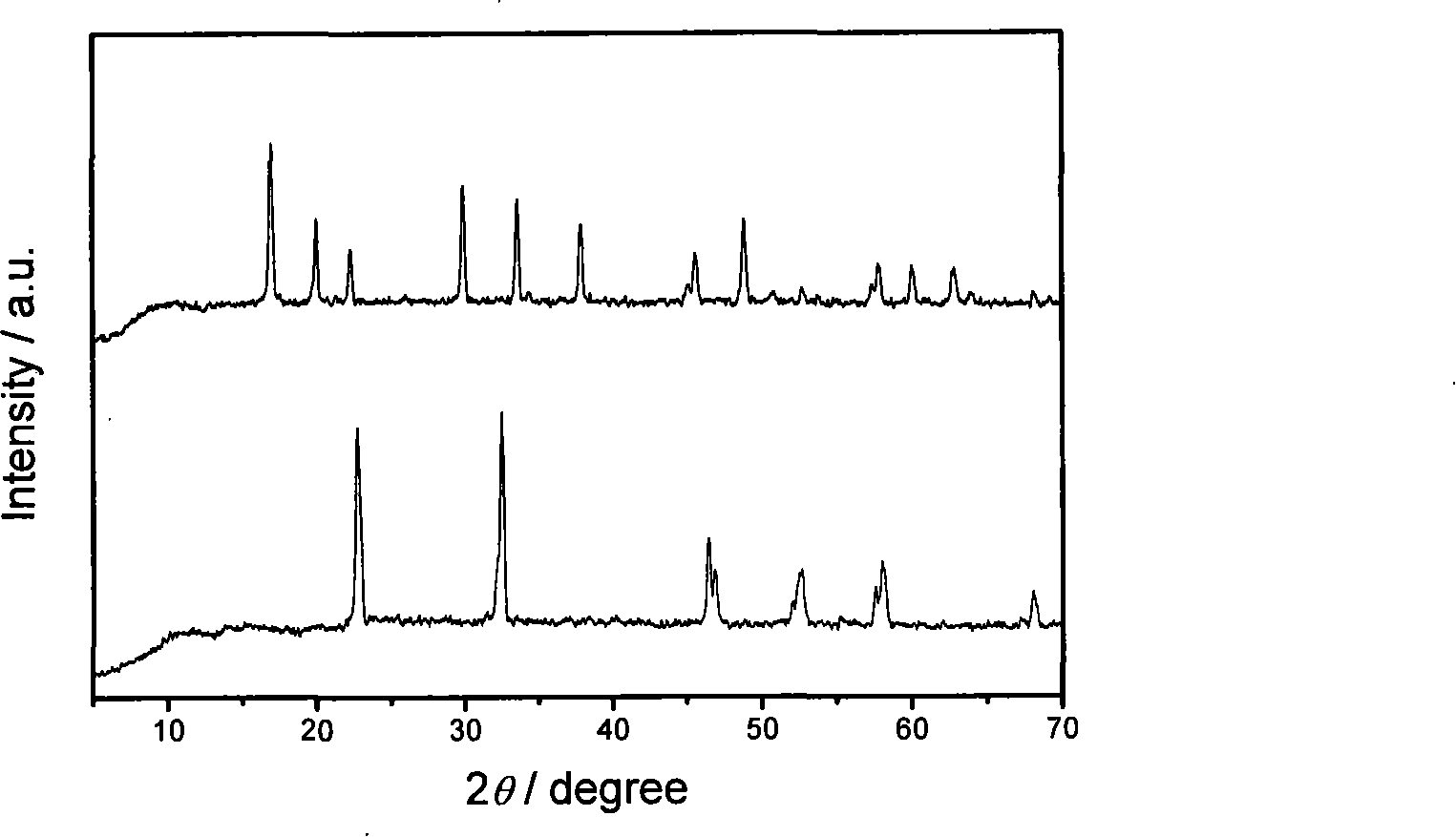

Embodiment 1

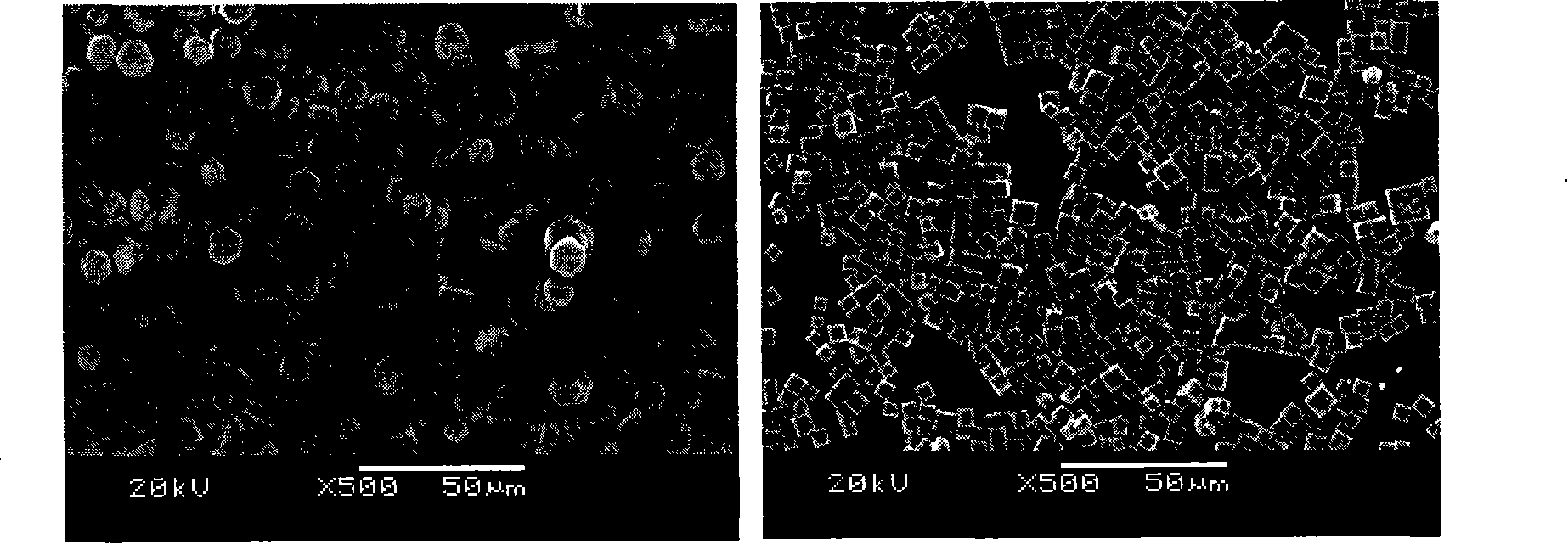

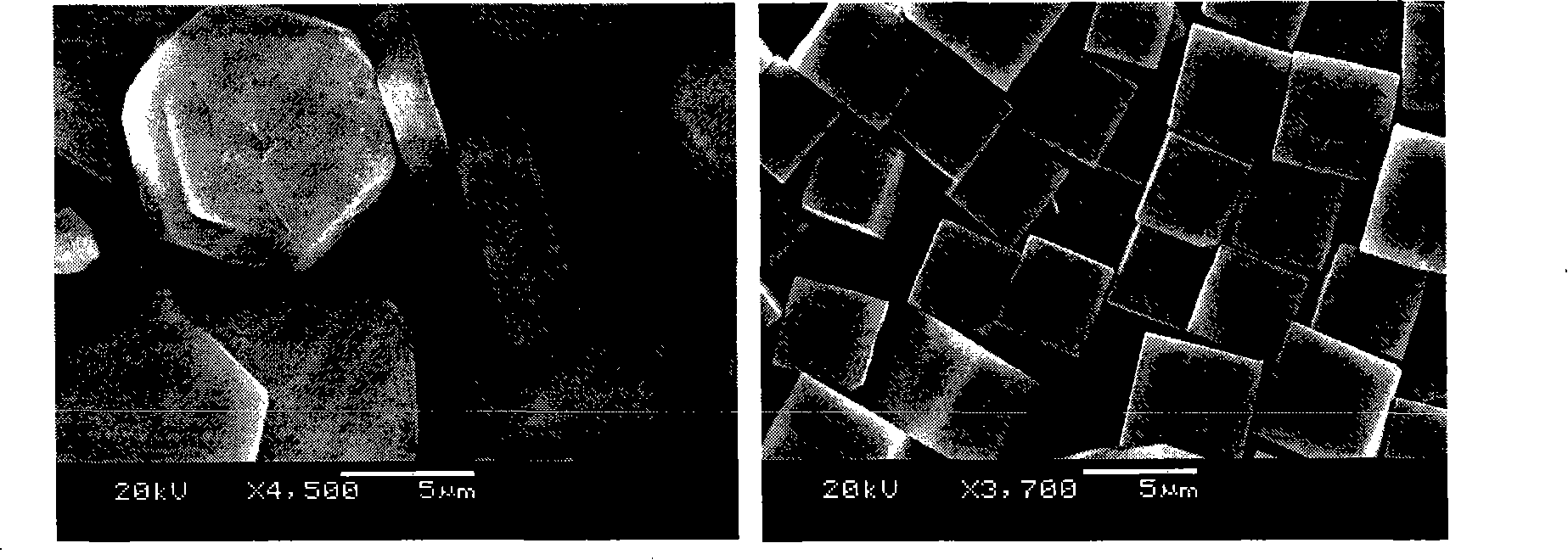

[0024] Nb with a molar ratio of 1:1 2 o 5 Add NaOH powder to 50 mL of the mixed solution of organic amine and distilled water, and stir at room temperature for 30 minutes at a stirring speed of 120 rpm. The obtained milky white precursor solution was transferred to an autoclave, and then the autoclave was sealed, reacted at 120°C for 5 hours, filtered, and distilled water and anhydrous a-body were used. The morphology of the sample is characterized as a sheet structure with a side length of 0.5-6 μm.

Embodiment 2

[0026] Nb with a molar ratio of 1:5 2 o 5 Add NaOH powder to 50 mL of the mixed solution of organic amine and distilled water, and stir at room temperature for 30 minutes at a stirring speed of 120 rpm. Transfer the obtained milky white precursor liquid into an autoclave, then seal the autoclave, filter at 200°C for 5 hours, wash with distilled water and absolute ethanol, and dry at 80°C for 2 hours to obtain trigonal and orthogonal miscible niobium Sodium Acid Powder.

Embodiment 3

[0028] Nb with a molar ratio of 1:10 2 o 5 Add NaOH powder to 50 mL of the mixed solution of organic amine and distilled water, and stir at room temperature for 30 minutes at a stirring speed of 120 rpm. Transfer the obtained milky white precursor solution to an autoclave, then seal the autoclave, filter at 120°C for 5 hours, wash with distilled water and absolute ethanol, and dry at 80°C for 2 hours to obtain orthogonal phase sodium niobate powder body. The morphology of the sample is characterized as a cubic structure with a side length of 2-10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com