Solid hydrogen storing device

A hydrogen storage device and solid technology, which are applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of easy hardening and accumulation of hydrogen storage alloy materials, complex heat transfer structure, and poor heat transfer effect. and other problems, to achieve the effect of improving service life and heat and mass transfer effect, good heat transfer effect, and reducing hardening and accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

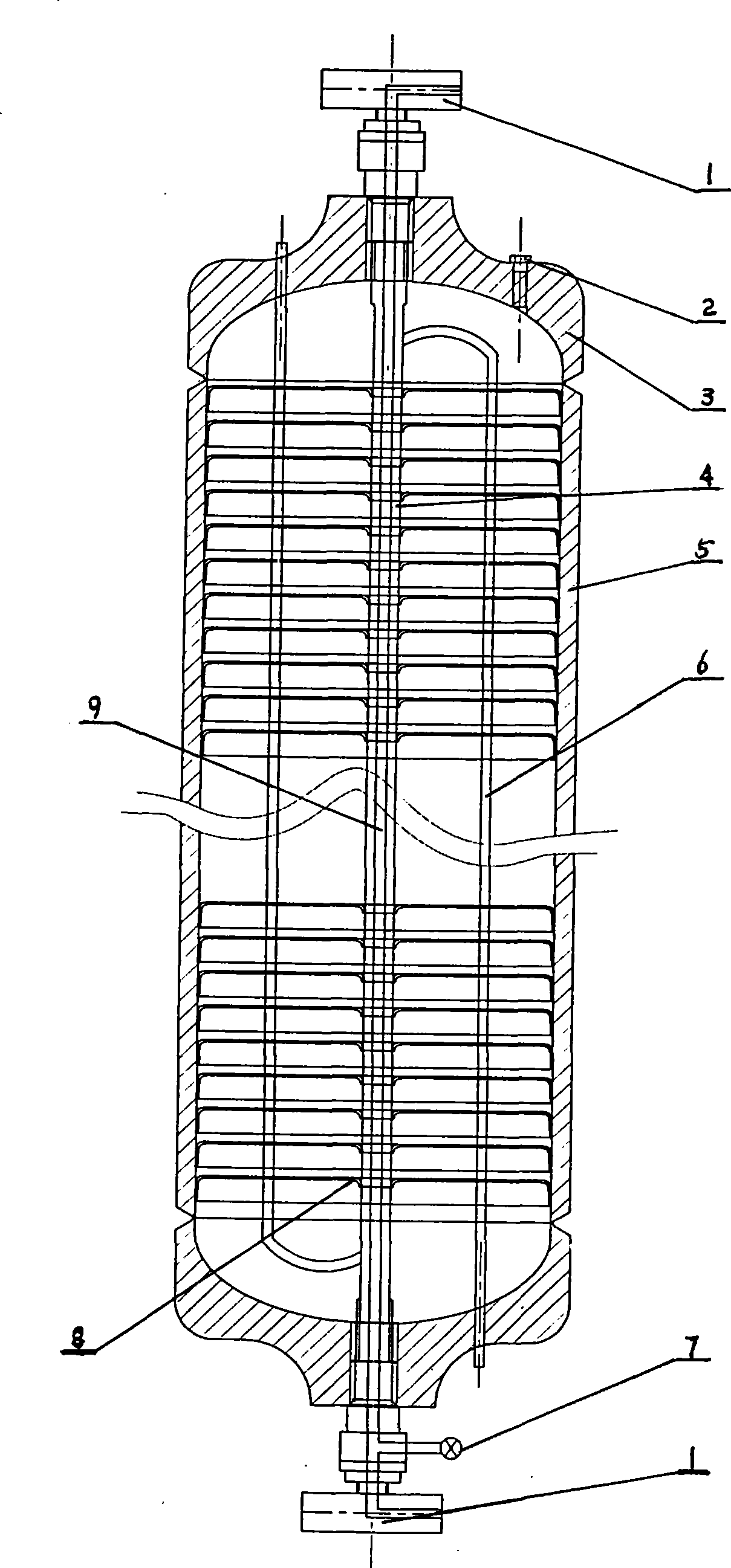

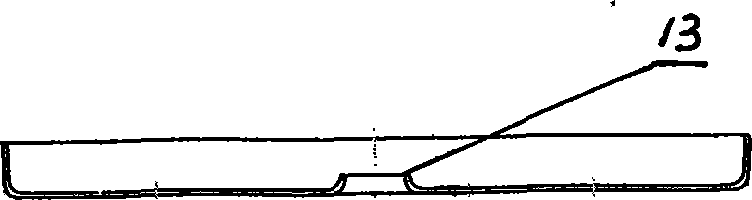

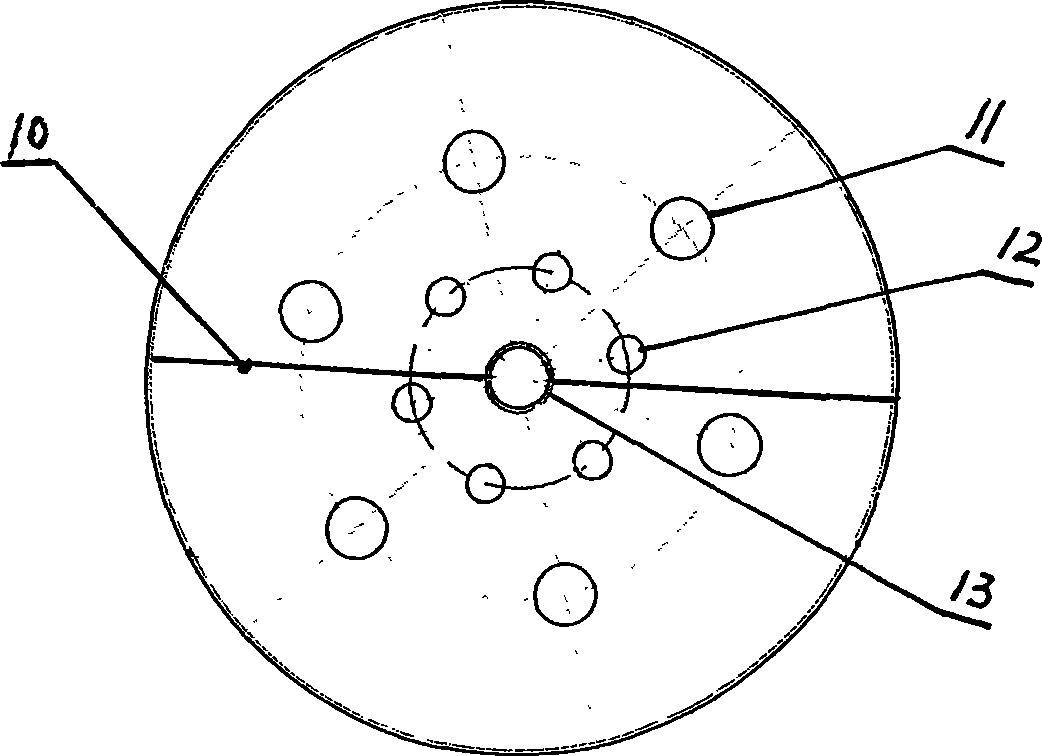

[0015] The present invention is an internal cooling and heating type, and the serpentine water circulation pipe 6 is arranged inside to communicate with several rows of heat conduction fins 8, and the heat conduction fins 8 and the cylinder body 5 form an interference fit, and the mass transfer mechanism can be selected from other metal powders such as stainless steel powder or copper powder The filter 4 is sintered after pressing or other metal or non-metallic materials with excellent thermal conductivity and mechanical properties. The two ends of the stainless steel tank are equipped with sealing heads 3, and the water outlet and water inlet are respectively set at On the sealing head 3 at both ends of the cylinder body 5, a manual valve is respectively installed at both ends of the cylinder body 5, so as to facilitate testing and maintenance. The center of the heat conduction sheet 8 has a central circular hole 13 that matches the filter 4, and six large circular holes 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com