Removable long-span thin car frame

A large-span, platform-based technology, which is used in stage installations, entertainment, installations for theaters and circuses, etc., can solve the problem of uneven load distribution, excessive wheel pressure, and difficulty in balancing the lateral horizontal additional load of the platform. and other problems, to achieve the effect of eliminating the horizontal additional load and reducing the wheel pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

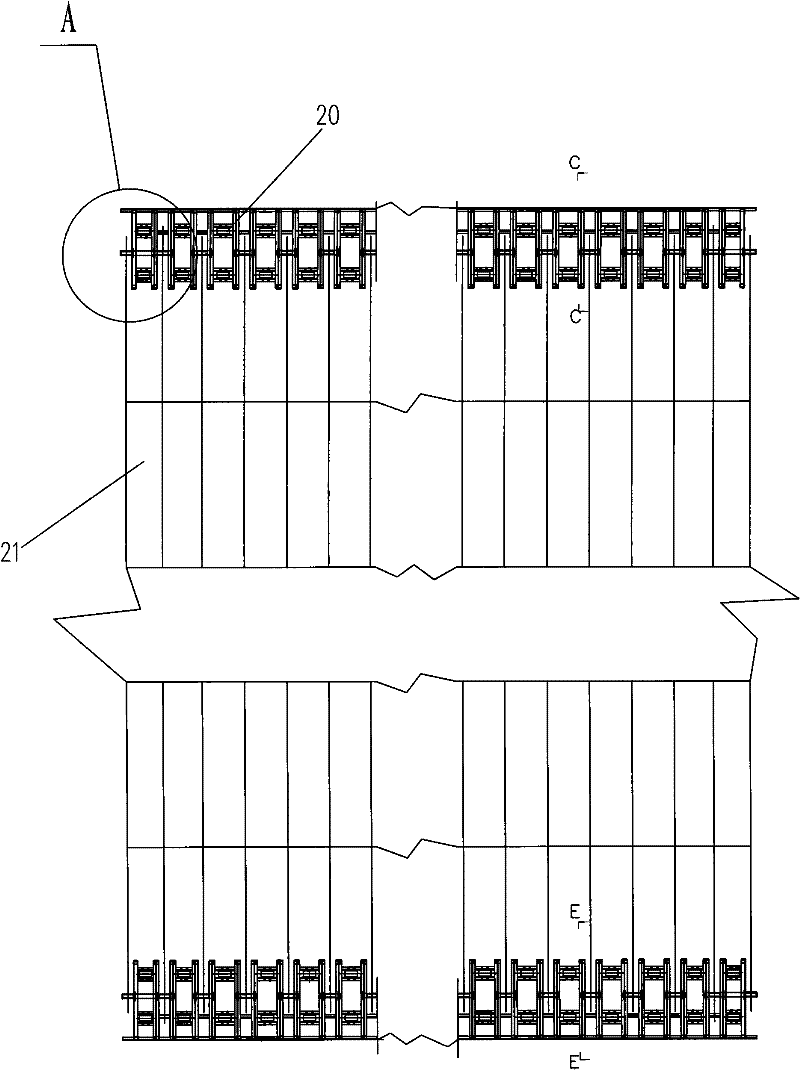

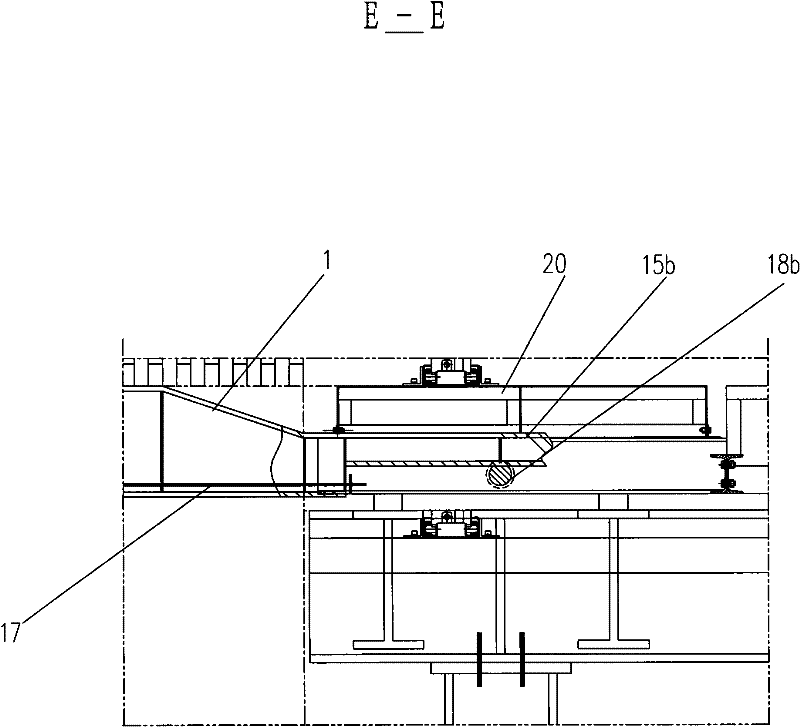

[0038] like figure 1 As shown, the mobile large-span thin platform vehicle platform of the present invention includes vehicle bodies 20 on both sides and a steel beam structure 21 arranged between the vehicle bodies 20 on both sides. Stressed steel beam structure (the following will be combined with the attached Figure 4-9 describe its structure in detail).

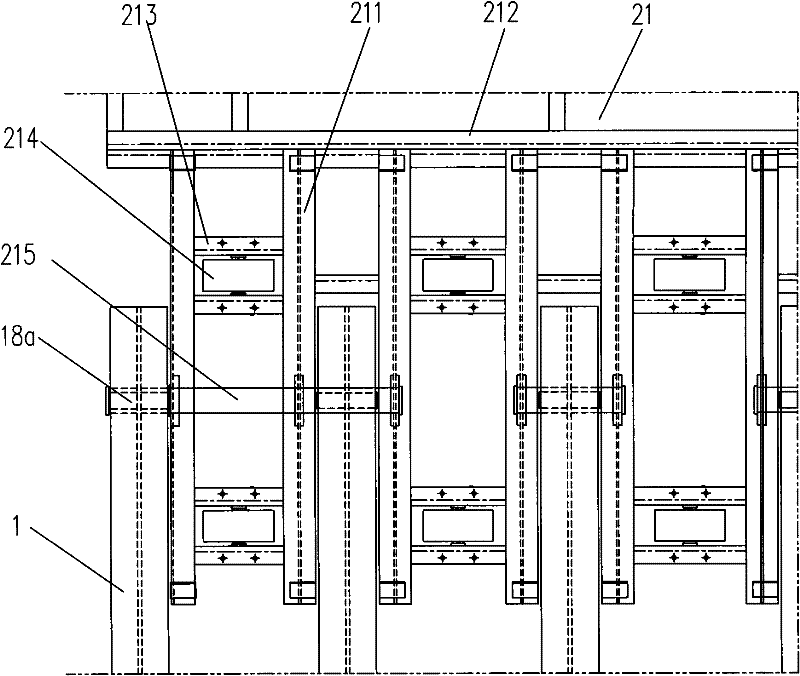

[0039] like figure 1 , 1a As shown, the steel beam structure 21 includes a plurality of main beams 1 extending in parallel, and the vehicle body 20 includes a plurality of parallel vehicle body beams 211, and each main beam 1 is arranged between pairs of vehicle body beams 211, and the paired A supporting frame 215 is arranged between the vehicle body beams 211, and the hinge shafts 18a, 18b are arranged in the supporting frame 215.

[0040] The outer end of the car body beam 211 of the car body 20 is provided with a side beam 212 perpendicular to the car body beam 211, and a supporting wheel frame 213 for placing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com