Horizontal forging press base

A forging press, horizontal technology, applied in the direction of forging/pressing/hammering machinery, forging/pressing/hammer device, manufacturing tools, etc. The problem of machine running stability and other issues can be eliminated, and the effect of eliminating horizontal additional load and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

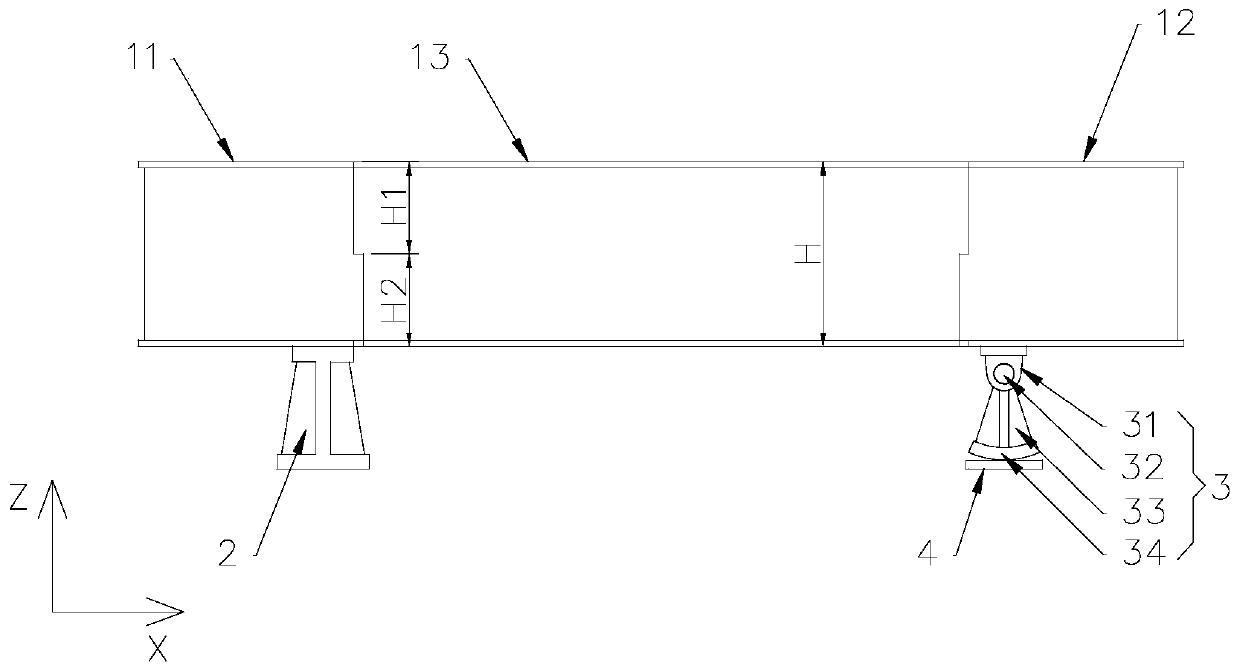

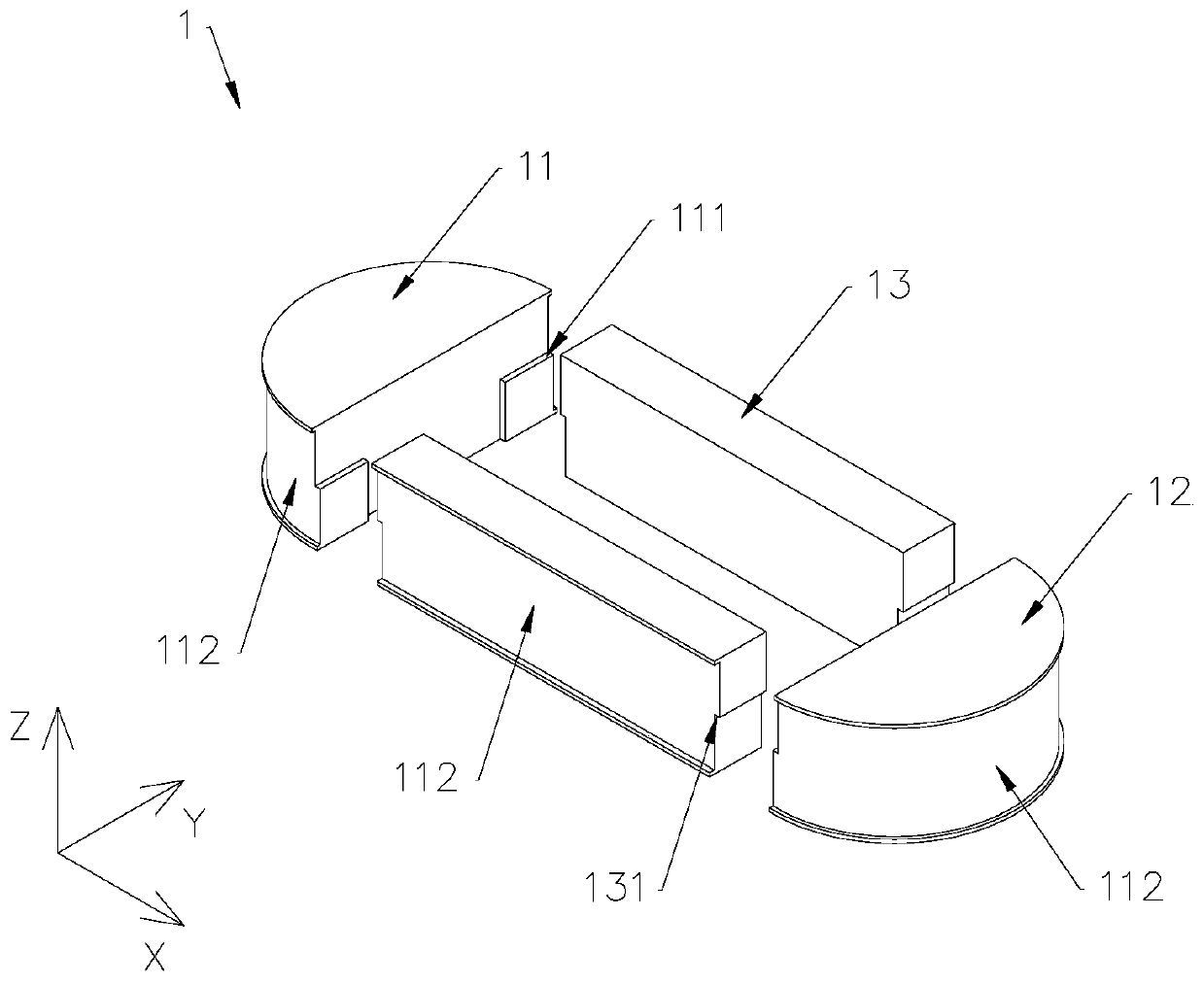

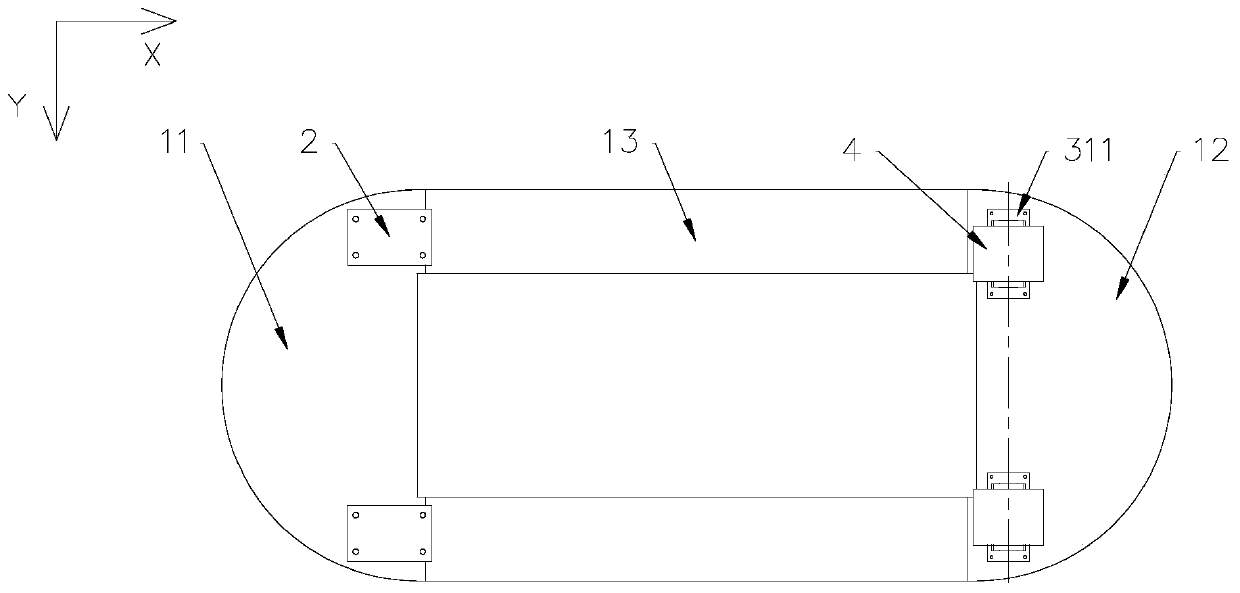

[0023] Such as Figure 1-4 As shown, assume that the coordinates are as shown in the figure, X-axis: indicates the longitudinal direction along the column 13, that is, the length direction of the column 13; Y-axis: indicates the axis perpendicular to the column 13, that is, the horizontal rotating shaft 32; Z axis: Indicates the up and down direction. The assumption of direction is for the convenience of embodiment description, and is not intended to limit the scope of protection of the present invention.

[0024] Such as Figure 1-4 As shown, a horizontal forging press base includes a frame 1 and two fixed supports 2 arranged at the bottom of the frame 1. The frame 1 is composed of the first beam 11 and the second beam 11 by a pre-tensioning mechanism. A rigid body formed by connecting beams 12 and several longitudinal columns 13 between the beams, the fixed support 2 is located at the bottom of the first beam 11, and the frame 1 passes through the fixed support 2 Fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com