Detergent resin composition for shaping apparatus

A technology of resin composition and molding machine, applied in the direction of organic cleaning composition, etc., can solve the problems of increased environmental load, unacceptable labor safety and sanitation, poor operation efficiency, etc., and achieve the effect of improving removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

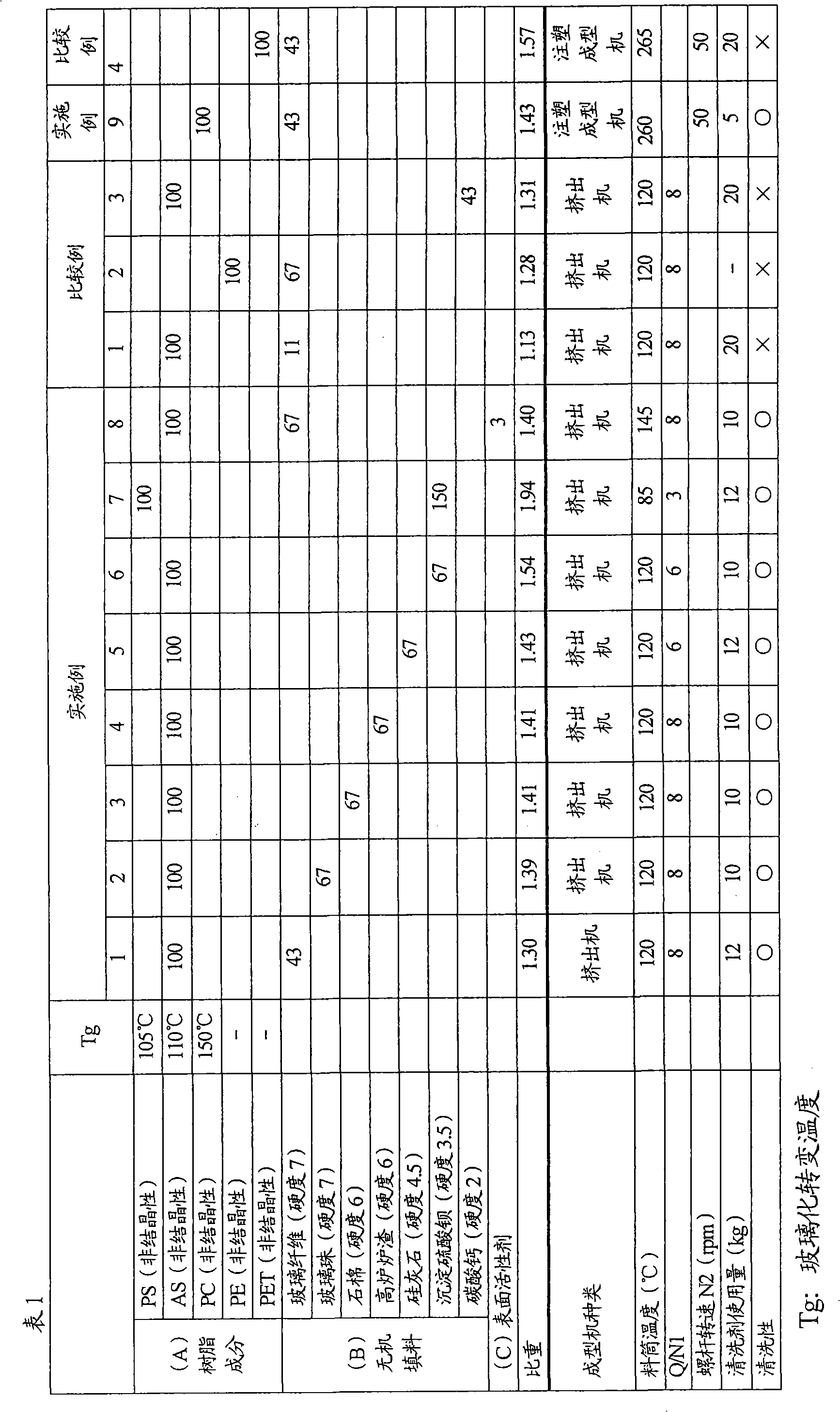

[0080] The various components shown in Table 1 were mixed, melted and kneaded with a twin-screw extruder (manufactured by Nippon Steel Works, TEX30α), processed into strands, and then cut with a pelletizer to form pellets. This pellet was used .

[0081]In the preparation of polyester resin-based powder coatings, cleaning was started when the production speed of the extruder with a barrel temperature of 120°C became half of the initial speed. The screw speed of the extruder was set at 10 rpm, and the cleaning agent composition (Q / N1=8, usage amount of 12 kg) was fed into the feeder at a feeding speed of 80 kg / hr. After pulling out the screw, clean it with a scraper for about 1 hour, then immerse it in a solvent for 1 day, and then perform surface treatment for about 30 minutes to reach a usable state.

Embodiment 2

[0083] The various components shown in Table 1 were mixed, kneaded with a twin-screw extruder (manufactured by Nippon Steel Works, TEX30α), processed into strands, and cut into pellets with a pelletizer. Such pellets were used.

[0084] In the preparation of polyester resin-based powder coatings, cleaning was started when the production speed of the extruder with a barrel temperature of 120°C became half of the initial speed. The screw speed of the extruder was set at 20 rpm, and the cleaning agent composition (Q / N1=8, usage amount of 10 kg) was fed into the feeder at a feeding speed of 160 kg / hr. After the screw is pulled out, there is little accumulation on the surface. Use a scraper to remove it for about 1 hour and perform surface treatment for about 30 minutes. It takes 1.5 hours in total to reach a usable state. No solvent impregnation was performed.

Embodiment 3

[0086] The various components shown in Table 1 were mixed, kneaded with a twin-screw extruder (manufactured by Nippon Steel Works, TEX30α), processed into strands, and cut into pellets with a pelletizer. Such pellets were used.

[0087] In the preparation of polyester resin-based powder coatings, cleaning was started when the production speed of the extruder with a barrel temperature of 120°C became half of the initial speed. The screw speed of the extruder was set at 20 rpm, and the cleaning agent composition (Q / N1=8, usage amount of 10 kg) was fed into the feeder at a feeding speed of 160 kg / hr. After the screw is pulled out, there is little accumulation on the surface. Use a scraper to remove it for about 1 hour and perform surface treatment for about 30 minutes. It takes 1.5 hours in total to reach a usable state. No solvent impregnation was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com