Perspective latent image of anopisthographic printing

A latent image, single-sided technology, applied in the field of anti-counterfeiting, can solve the problems of difficulty in see-through latent image, unidentifiable patterns, high precision, etc., and achieve the effects of strong anti-counterfeiting performance, improved aesthetics, and high metallic luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

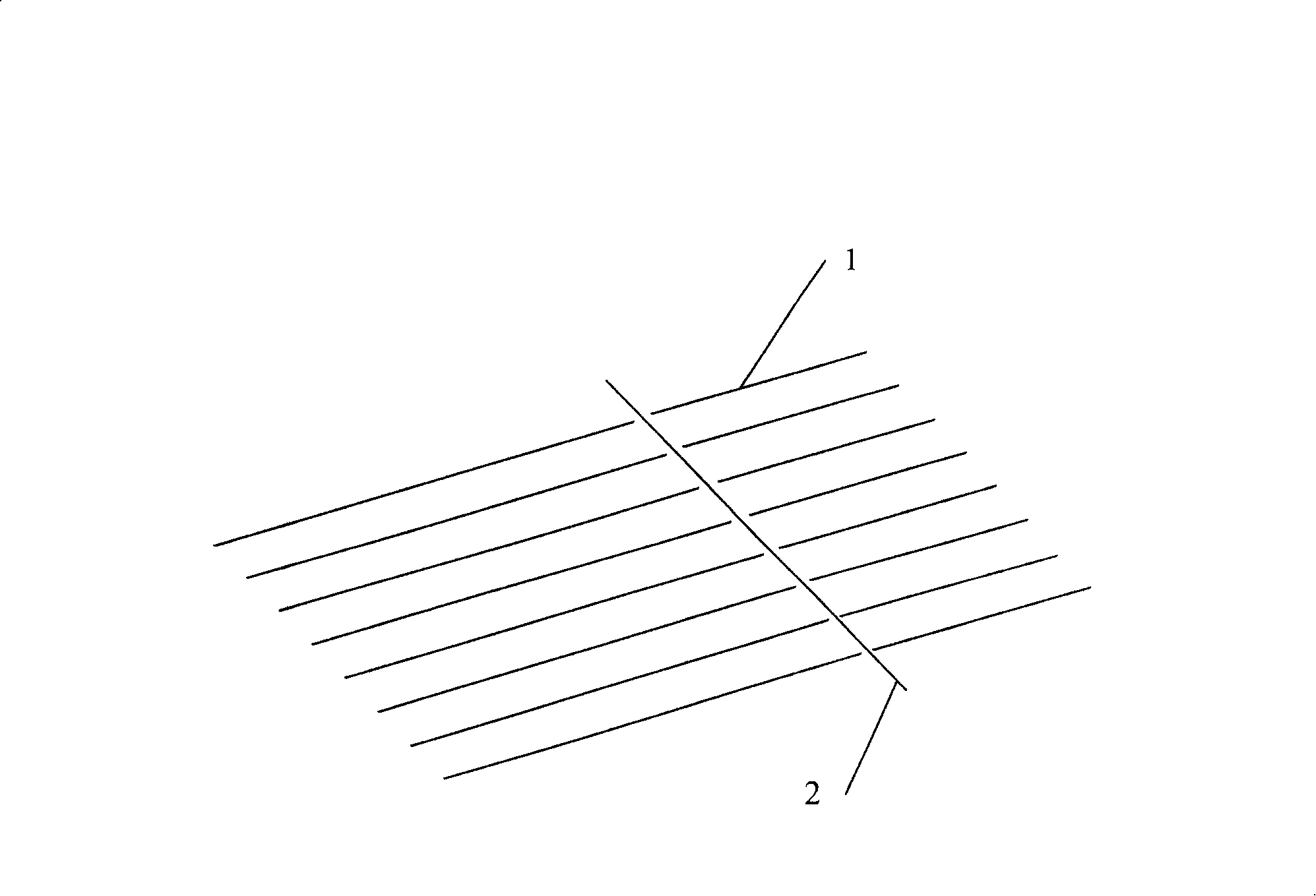

[0033] Embodiment 1: Utilize the software of engraving gravure design to generate the base pattern and the perspective latent image pattern made of lines, the lines constituting the perspective latent image pattern and the lines forming the pattern are as follows figure 1 In the arrangement shown, the two intersect at an angle of 90° but do not overlap each other, and the density of the lines forming the perspective latent image pattern is 5 lines per millimeter. Then through the existing engraving gravure printing process, the see-through latent image pattern and the base pattern are printed on one side of the carrier (or referred to as the substrate) at one time with metallic ink. The carrier can be paper, such as banknote paper, security paper , license paper or bill paper, or plastic, rubber, glass and other items with a certain degree of light transmission.

[0034] The composition and weight percentage of the metal ink used to form the see-through latent image are as fol...

Embodiment 2

[0048] Embodiment 2: The basic structure and implementation method are as in embodiment 1, wherein the density of lines constituting the see-through latent image pattern is 6 per millimeter, and is used for printing the metal ink of the lines of the see-through latent image and the base pattern on one side on the carrier The ingredients and percentages are as follows:

[0049] Flake aluminum powder 20%

[0050] Alkyd Oil 15%

[0051] High acid value phenolic resin oil 20%

[0052] Pure Phenolic Oil 10%

[0053] Fumed silica 5%

[0054] Transparent Calcium Carbonate 15%

[0055] Surfactant 6.7%

[0056] Polyethylene wax 6%

[0057] Mineral oil 2%

[0058] Desiccant 0.3%

Embodiment 3

[0059] Embodiment 3: The basic structure and implementation method are as in Embodiment 1, wherein the density of lines constituting the see-through latent image pattern is 7 per millimeter, and is used for printing the metal ink of the lines of the see-through latent image and the base pattern on one side on the carrier The ingredients and percentages are as follows:

[0060] Flake copper powder 24%

[0061] Alkyd Oil 10%

[0062] High acid value phenolic resin oil 24%

[0063] Pure Phenolic Oil 8%

[0064] Fumed silica 3%

[0065] Transparent Calcium Carbonate 16%

[0066] Surfactant 5.6%

[0067] Polyethylene wax 6%

[0068] Mineral oil 3%

[0069] Desiccant 0.4%

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com