Method for manufacturing high-titanium ferrotitanium

A manufacturing method and technology of ferrotitanium, which is applied in the field of high-titanium ferrotitanium, can solve problems such as insufficient vacuum degree, high ferrotitanium gas content, and pollution of furnace materials, and achieve less inclusions, high titanium recovery rate, and less smelting pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

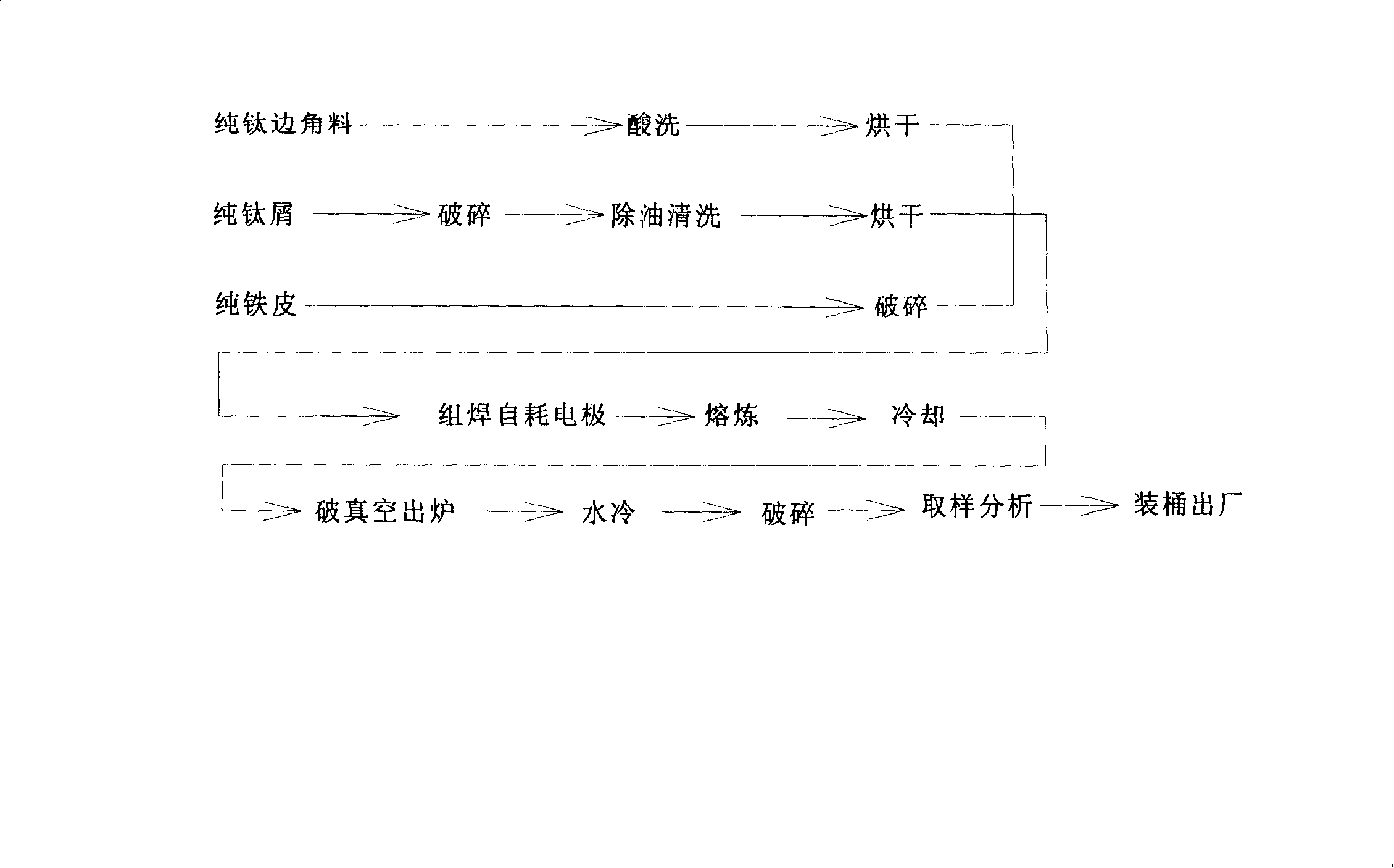

[0010] Embodiment, operate according to the process flow chart of Fig. 1.

[0011] 1. Processing technology

[0012] 2. Electrode parameters

[0013] Electrode weight 137.5 kg

[0014] Electrode specification 200*200*1800(mm)

[0015] Titanium theoretical ratio 73.58%

[0016] 3. Process parameters related to smelting

[0017] Melting current 7~8 thousand amperes

[0018] Melting voltage 28~30 volts

[0019] Melting vacuum 1.0~4.5 Pa

[0020] Cooling time 0.75~1 hour

[0021] 4. Based on random sampling results of production experiments (%)

[0022] C S P Si Al Ti N

[0023] Sample 1 0.10 0.005 0.010 0.13 0.32 73.34 0.018

[0024] Sample 2 0.10 0.005 0.011 0.12 0.33 73.49 0.022

[0025] Sample three 0.10 0.005 0.011 0.14 0.35 73.67 0.024 The rest is iron.

[0026] 5. Meet the requirements of ISO5454-1980 (E).

[0027] Vacuum-breaking, air-cooling or water-cooling, crushing to produce high-titanium ferro-titanium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com