Combined vanadium leaching method for stone coal

A technology of stone coal and stone coal mines, applied in the direction of improving process efficiency, etc., can solve the problems of acid and alkali waste, high content of waste acid, etc., achieve high-efficiency leaching, increase oxidation conversion rate and leaching rate, and increase leaching speed and leaching rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

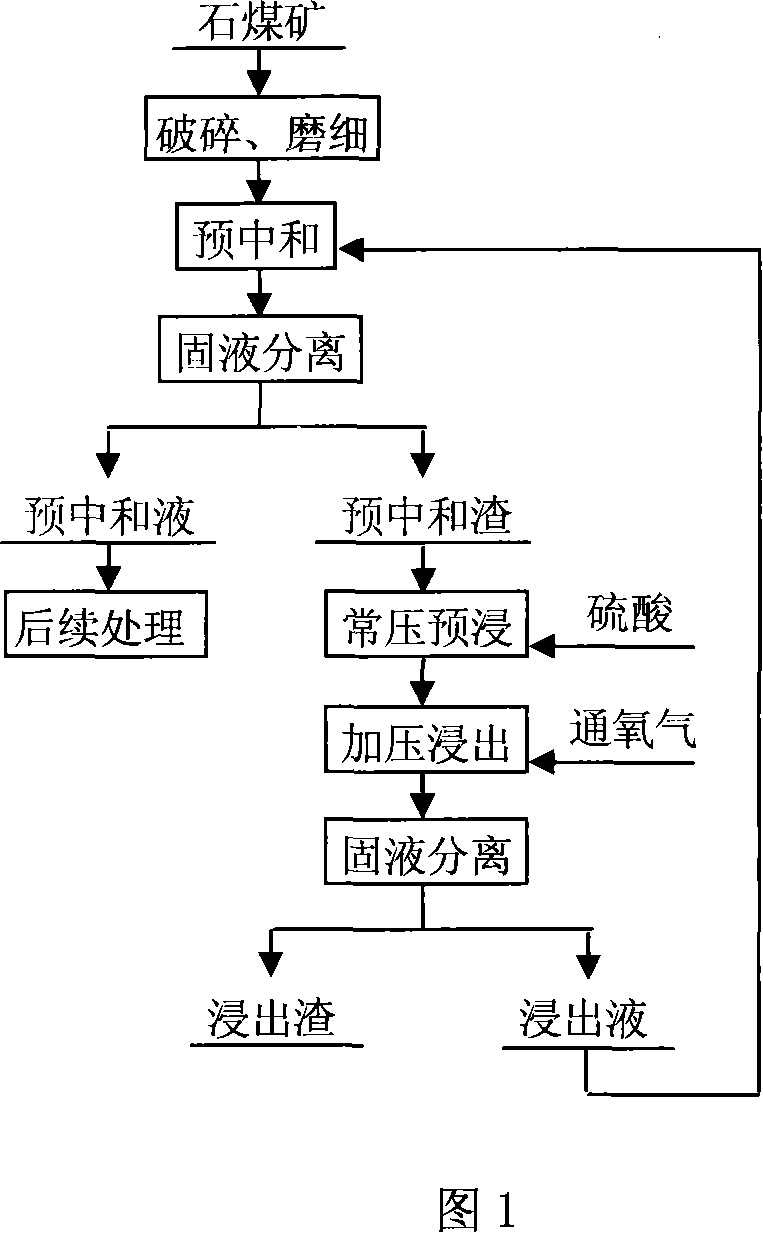

Image

Examples

Embodiment 1

[0012] Embodiment 1: Stone coal contains 0.51% vanadium.

[0013] ① Mix the stone coal ore and the leaching solution according to the liquid-solid ratio of 1.2:1, then put them into the pre-neutralization tank for neutralization reaction, control the temperature in the tank to 85°C, and neutralize for 120 minutes. After the pre-neutralization, the liquid-solid separation is carried out to obtain the pre-neutralization slag and the pre-neutralization liquid with qualified acidity for the next step of vanadium extraction. ②Mix the pre-neutralized slag and the sulfuric acid solution with an acidity of 300g / L according to the liquid-solid ratio of 1.2:1, and then pump it continuously into the atmospheric pressure pre-soaking tank, control the temperature in the tank to 85°C, and pre-soak for 240 minutes. ③After normal pressure prepreg, use a metering pump to directly pump the slurry into the autoclave lined with ceramic tiles, use steam or tap water to control the temperature in t...

Embodiment 2

[0015] Embodiment 2: Stone coal contains 1.84% vanadium.

[0016] ① Mix the stone coal ore and the leaching solution according to the liquid-solid ratio of 1.5:1, then put them into the pre-neutralization tank for neutralization reaction, control the temperature in the tank to 90°C, and neutralize for 210 minutes. After the pre-neutralization, the liquid-solid separation is carried out to obtain the pre-neutralization slag and the pre-neutralization liquid with qualified acidity for the next step of vanadium extraction. ②Mix the pre-neutralization slag and the sulfuric acid solution with an acidity of 350g / L according to the liquid-solid ratio of 1.5:1, and then pump it into the atmospheric pressure pre-soaking tank continuously, control the temperature in the tank to 90°C, and pre-soak for 360 minutes. ③After normal pressure prepreg, use a metering pump to directly pump the slurry into the autoclave lined with ceramic tiles, use steam or tap water to control the temperature i...

Embodiment 3

[0018] Embodiment 3: Stone coal contains 0.21% vanadium.

[0019] ① Mix the stone coal ore and the leaching solution according to the liquid-solid ratio of 1.2:1, then put them into the pre-neutralization tank for neutralization reaction, control the temperature in the tank to 90°C, and neutralize for 60 minutes. After the pre-neutralization, the liquid-solid separation is carried out to obtain the pre-neutralization slag and the pre-neutralization liquid with qualified acidity for the next step of vanadium extraction. ②Mix the pre-neutralization slag and the sulfuric acid solution with an acidity of 30g / L according to the liquid-solid ratio of 1.2:1, and then pump it into the normal-pressure pre-soaking tank continuously. Control the temperature in the tank to 90°C and pre-soak for 60 minutes. ③After normal pressure prepreg, use a metering pump to directly pump the slurry into the autoclave lined with titanium material, use steam or tap water to control the temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com