Method for preparing lipophilic nano SiO2 powder

A lipophilic, nano-technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed organosilicon compound treatment, etc., can solve the problems that are difficult to solve by recycling dispersed phase, unsuitable for industrial production, and achieve controllable reaction level, easy The effect of industrialized production and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

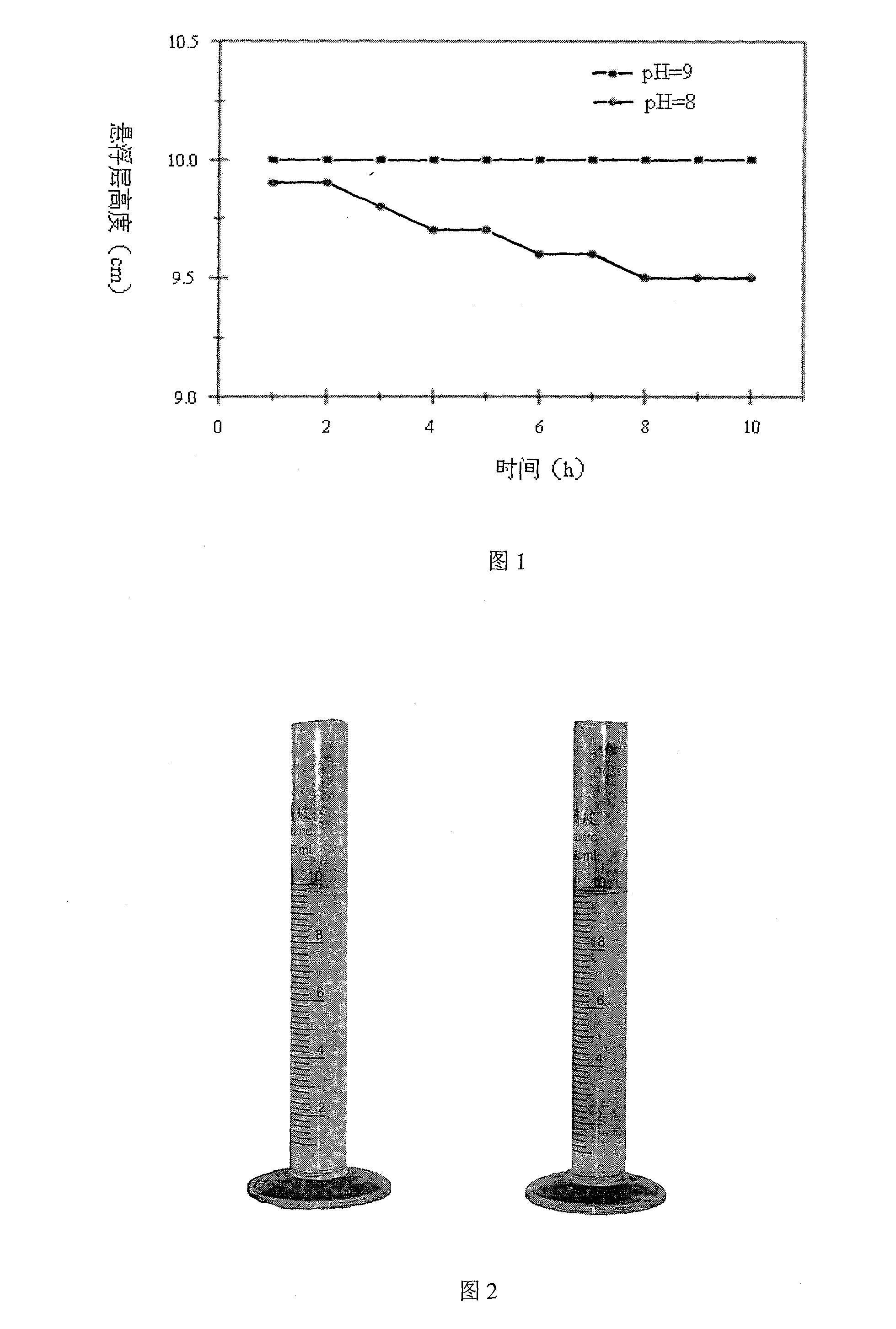

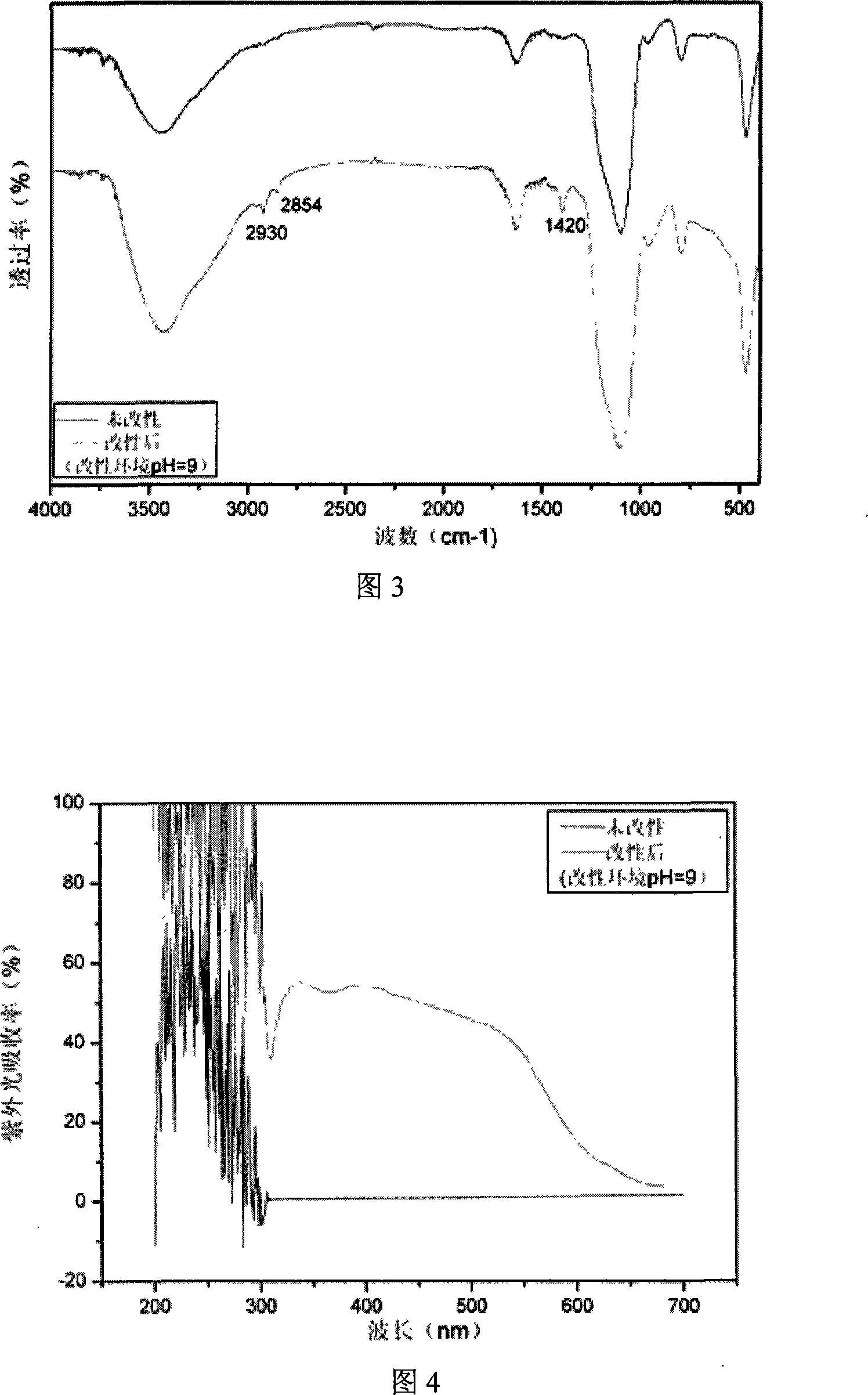

[0029] Weigh 4g of nano-SiO 2 Put the powder into a beaker, add 100ml deionized water, and stir at the same time; then add 15mlH to the beaker 2 o 2 (30wt%) and 15ml of absolute ethanol solution, ultrasonically disperse for 30min, seal with a Petri dish, and put it in a cool place for 12h. The mixed suspension was added to a three-necked flask, heated to 50° C. using an oil bath, and mechanically stirred at the same time at a stirring speed of 400 rpm. Take 120ml of ethyl acetate solution and add it into the three-necked flask. Use 0.1mol / L ammonia water to adjust the pH value of the reaction environment to 9, then take 0.5ml γ-(methacryloyloxy)propyltrimethoxysilane and add it to the three-necked flask, and react for 8h (with the modified lipophilic powder body completely into the organic phase shall prevail). After the reaction is finished, let stand for 6 hours to separate the water phase and the oil phase, then separate the organic phase with a separatory funnel, heat ...

Embodiment 2

[0031] Weigh 4g of nano-SiO 2 Put the powder into a beaker and add 100ml of deionized water while stirring; then add 15ml of H 2 o 2 (30wt%) and 15ml of absolute ethanol solution, ultrasonically disperse for 30min, seal with a Petri dish, and put it in a cool place for 12h. It was added into a three-necked flask, heated to 55° C. with an oil bath, and mechanically stirred at the same time at a stirring speed of 500 rpm. Take 120ml of ethyl acetate solution and add it into the three-necked flask. Use 0.1mol / L ammonia water to adjust the pH value of the reaction environment to 8, then take 0.5ml γ-(methacryloyloxy)propyltrimethoxysilane and add it to the three-necked flask, and react for 8h (with the modified lipophilic powder body completely into the organic phase shall prevail). After the reaction is finished, let it stand for 6 hours to separate the water phase and the oil phase, then use a separatory funnel to separate the organic phase, heat the organic phase to 80°C fo...

Embodiment 3

[0033] Weigh 4g of nano-SiO 2 Put the powder into a beaker and add 100ml deionized water while stirring; then add 8mlH to the beaker 2 o 2 (30wt%) and 8ml of absolute ethanol solution, ultrasonically disperse for 30min, seal with a petri dish, and put it in a cool place for 12h. The mixed dispersion liquid was put into a three-necked flask, heated to 60° C. using an oil bath, and mechanically stirred at the same time at a stirring speed of 400 rpm. Take 130ml of ethyl acetate solution and add it into the three-necked flask. Use 0.1mol / L ammonia water to adjust the pH value of the reaction environment to 9, then take 0.2ml of γ-(methacryloyloxy)propyltrimethoxysilane and add it to the three-necked flask, and react for 10h (with the modified lipophilic powder body completely into the organic phase shall prevail). After the reaction is finished, let it stand for 6 hours to separate the water phase and the oil phase, then use a separatory funnel to separate the organic phase, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com