Method for processing liquid ammonia of cotton wire union cloth

A technology of interwoven fabrics and processing methods, applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., can solve the problems of protein fiber damage, uneven penetration, high viscosity of caustic soda, etc., and achieve elasticity and hand feeling Increased, soft touch, no need to iron the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

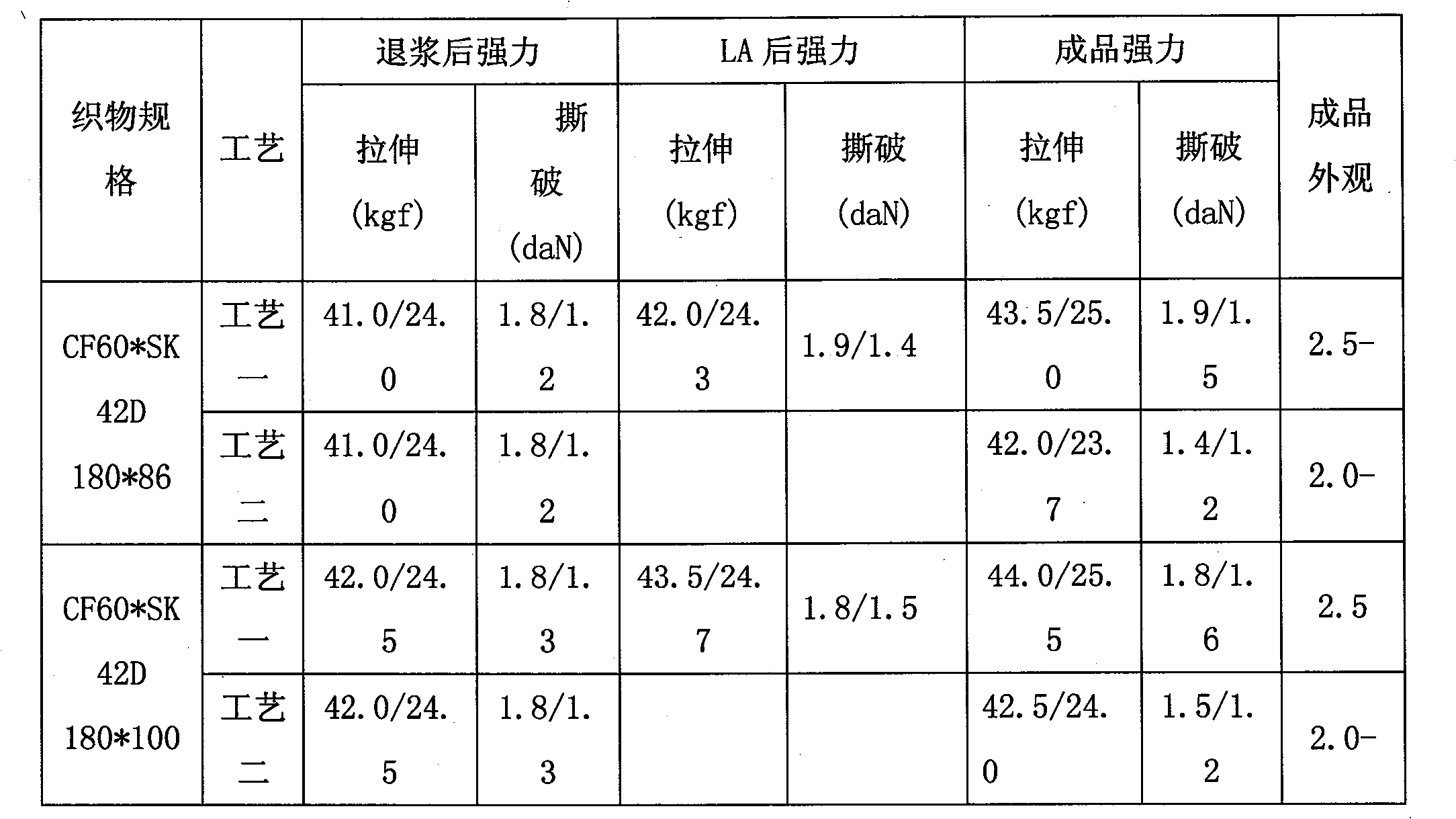

Examples

Embodiment 1

[0041] Embodiment 1: A processing method for cotton silk interwoven fabrics, comprising the following steps: ① singeing ② desizing ③ liquid ammonia ④ shaping ⑤ pre-shrinking five steps, the step ③ includes cloth feeding A → pre-drying B → Air cooling C→ padding liquid ammonia D→ steaming E→ water washing F→ drum drying G→ cloth falling H;

[0042] Step A: The cloth feeding speed is 35.0m / min, the cloth feeding width is 146.0cm, and the cloth feeding suction edge pressure is 0.008MPa;

[0043] Step B: The temperature of the pre-drying cylinder is 120°C, the tension of the first drying cylinder is 175N, and the tension of the second drying cylinder is 175N;

[0044] Step D: the temperature of the front section of the padding liquid ammonia treatment chamber is 70°C, and the temperature of the rear section of the padding liquid ammonia treatment chamber is 80°C;

[0045] Step E: The temperature of the steaming chamber is 110°C, the cylinder steam pressure of the steaming chamber...

Embodiment 2

[0048] Step H: The rolling pressure of the doffing rack is 0.2MPa, the doffing width is 131.0cm, and the doffing speed is 20.0m / min. Embodiment 2: A method for processing cotton and silk interwoven fabrics, which is characterized in that it includes the following steps ① Singeing ② Desizing ③ Liquid ammonia ④ Shaping ⑤ Pre-shrinking five steps, the step ③ includes cloth feeding A → pre-drying B → air cooling C → padding liquid ammonia D → steaming E → washing F → drum Drying G → falling cloth H;

[0049] Step A: The cloth feeding speed is 40.0m / min, the cloth feeding width is 150.0cm, and the pressure of the cloth feeding edge suction device is 0.010MPa;

[0050] Step B: The temperature of the pre-drying cylinder is 130°C, the tension of the first drying cylinder is 200N, and the tension of the second drying cylinder is 200N;

[0051] Step D: the temperature of the front stage of the padding liquid ammonia treatment chamber is 75°C, and the temperature of the rear stage of th...

Embodiment 3

[0055] Step H: The rolling pressure of the doffing frame is 0.18MPa, the doffing width is 140.0cm, and the doffing speed is 30.0m / min. Embodiment 3: A processing method for cotton silk interwoven fabrics, characterized in that it comprises the following steps: 1. singeing 2. desizing 3. liquid ammonia 4. shaping 5. 5. pre-shrinking, and the step 3. includes cloth feeding A → pre-drying Drying B→air cooling C→dipping liquid ammonia D→steaming E→washing F→drum drying G→cloth falling H;

[0056] Step A: The cloth feeding speed is 45.0m / min, the cloth feeding width is 152.0cm, and the pressure of the cloth feeding edge suction device is 0.102MPa;

[0057] Step B: The temperature of the pre-drying cylinder is 140°C, the tension of the first drying cylinder is 230N, and the tension of the second drying cylinder is 230N;

[0058] Step D: the temperature of the front section of the padding liquid ammonia treatment chamber is 80°C, and the temperature of the rear section of the paddin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com