Process for producing composite electrically-conducting paint

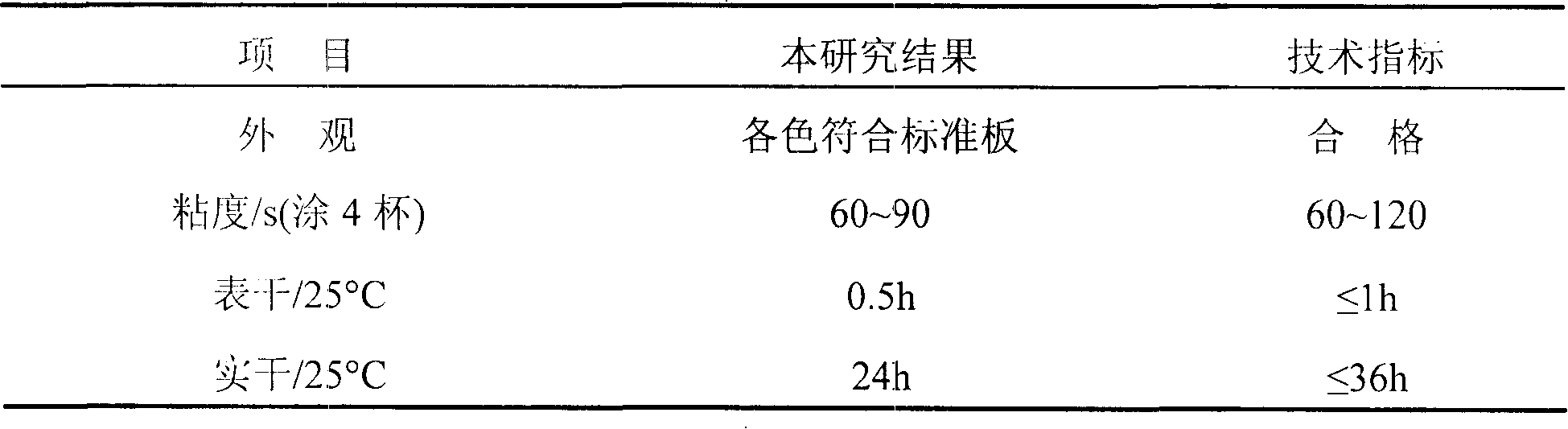

A composite conductive and coating technology, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor conductive effect of coatings, unstable coating performance, poor dispersion stability, etc., to achieve smooth appearance, conductive Good performance, good friction resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

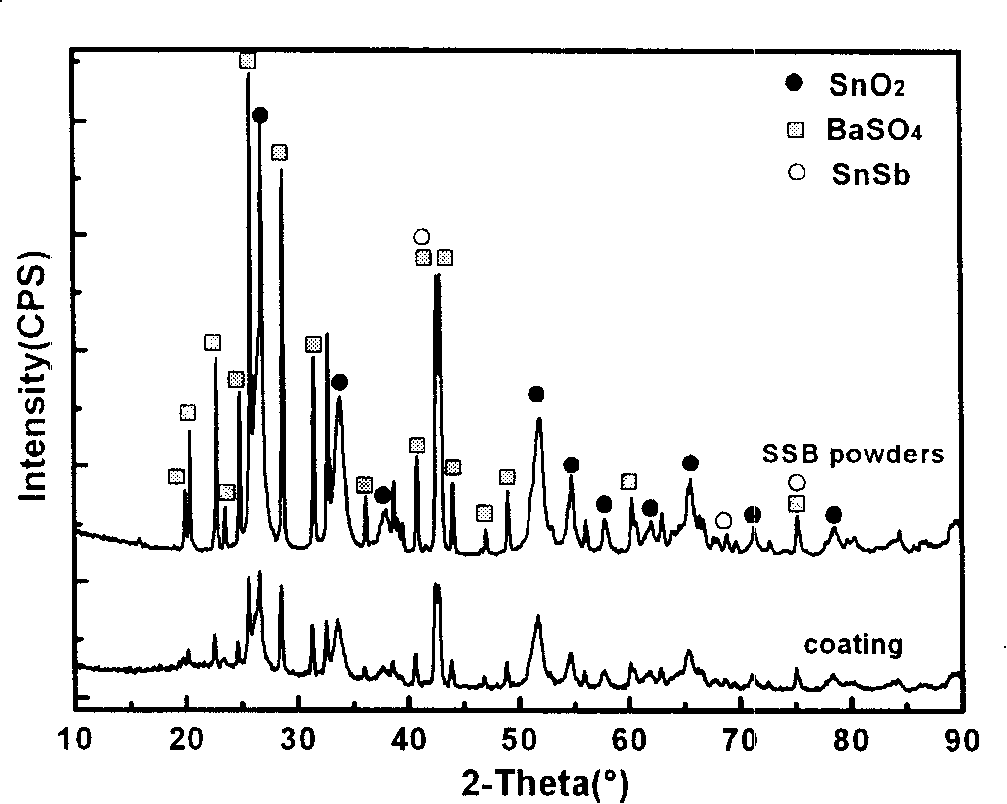

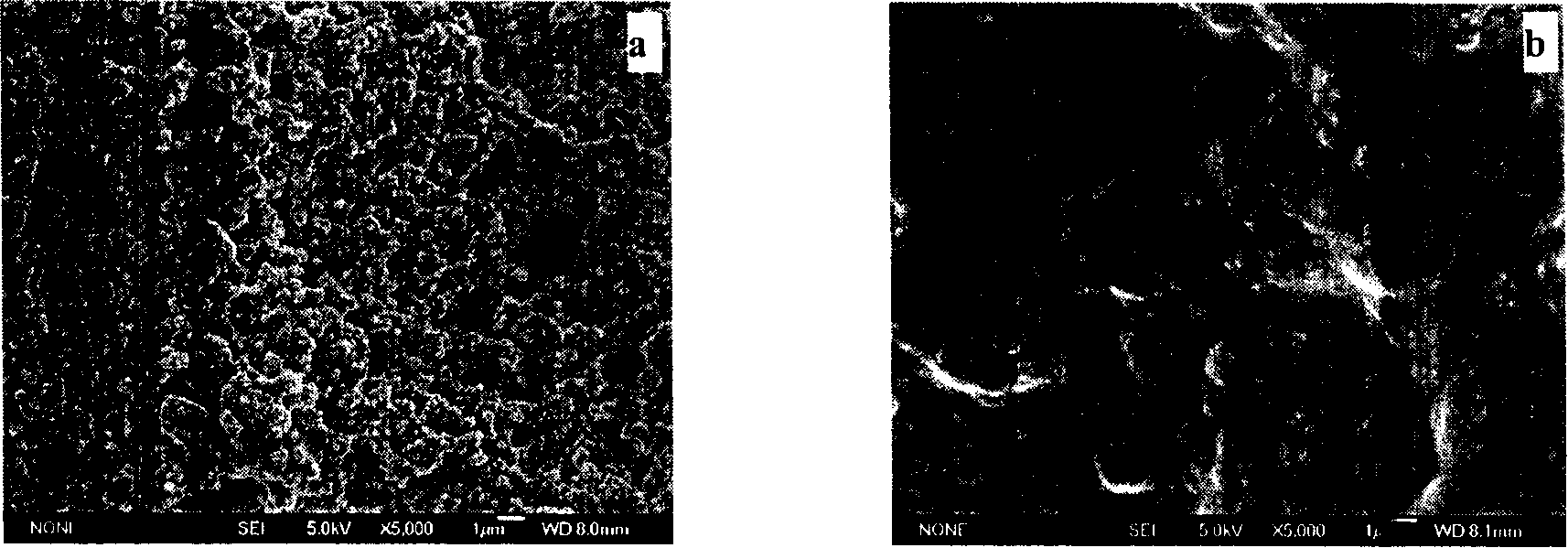

[0023] 2 kg of barite as it is is ball-milled in a stirring ball mill for 7.5 hours, the ball-milling medium is zirconia balls, and the weight ratio of balls to materials is 4:1 to obtain the base of the composite conductive filler for use. Take barite with a solid content of 30% and place it in 200ml of distilled water, and under constant stirring, add SnCl with a concentration of 0.4mol / L 4 4H 2 O and SbCl 3 The mixed acidic solution was dropped into the distilled water filled with barite powder, and at the same time, 60% ammonia solution was added to control the pH of the final titration = 3, after stirring for 1 hour, it was suction filtered, dried at 100°C, and roasted at 700°C for 1 hour to obtain a composite conductive filler Sb-doped SnO 2 / BaSO 4 (SSB). 150 g of SSB composite conductive powder was modified with 1% silane coupling agent, the modification time was 30 min, and the modification temperature was 80°C. Fully disperse 100g of acrylic resin and additives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com