Method for preparing spherical nano silver powder

A technology of spherical nano-silver and silver nitrate, which is applied in the field of preparation of spherical nano-silver powder, can solve the problems of no further purification, and achieve the effect of regular shape, smooth surface and high process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

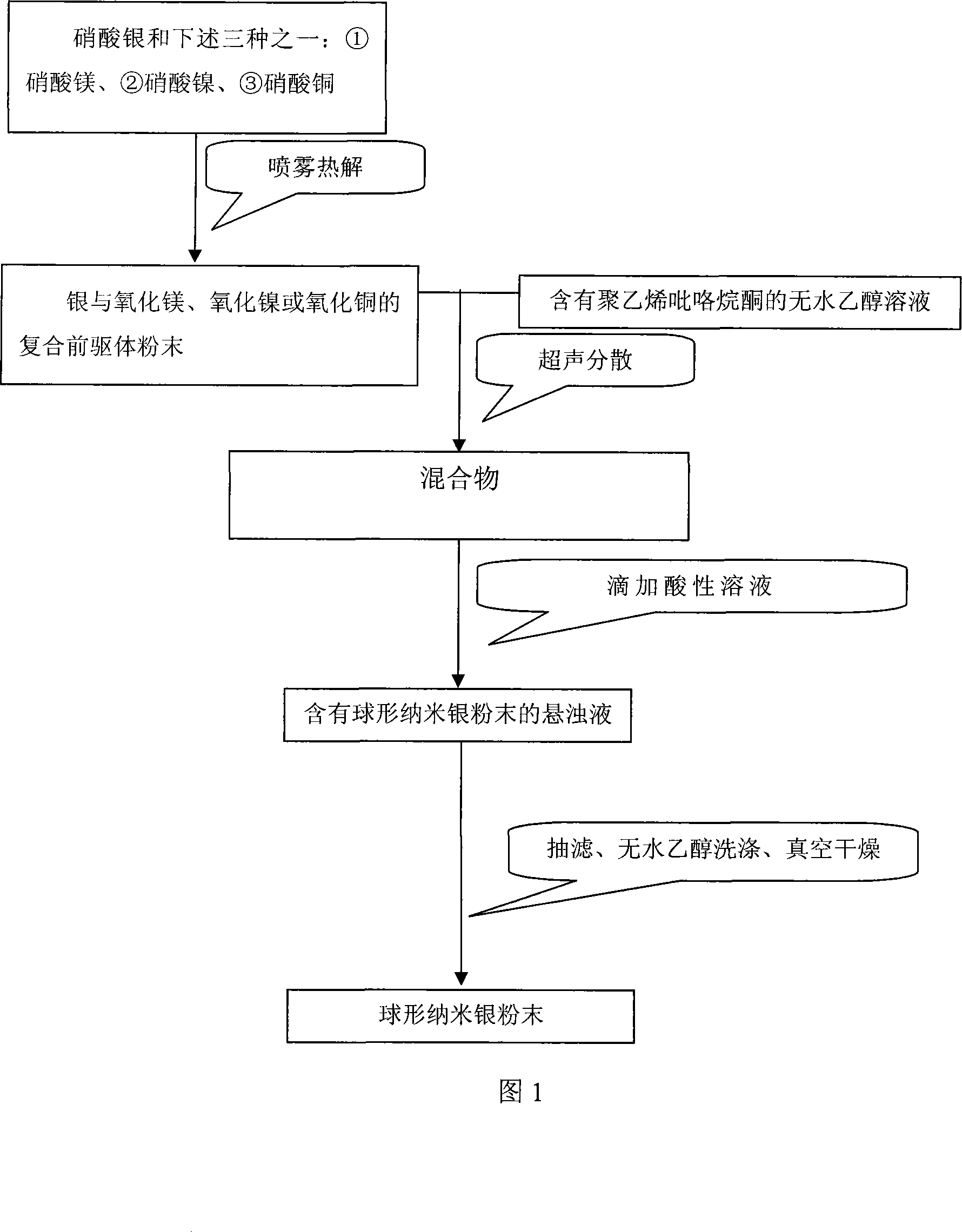

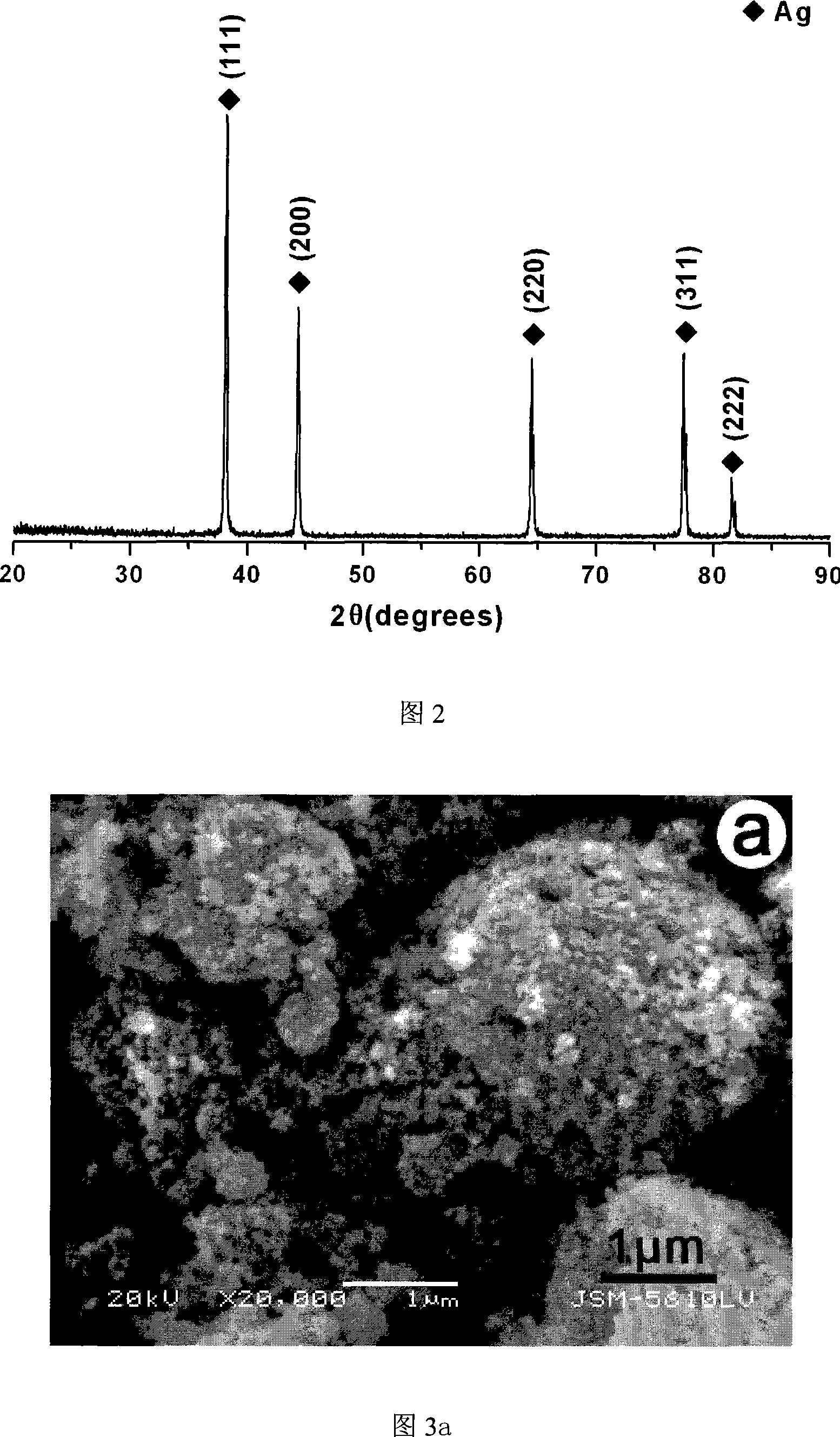

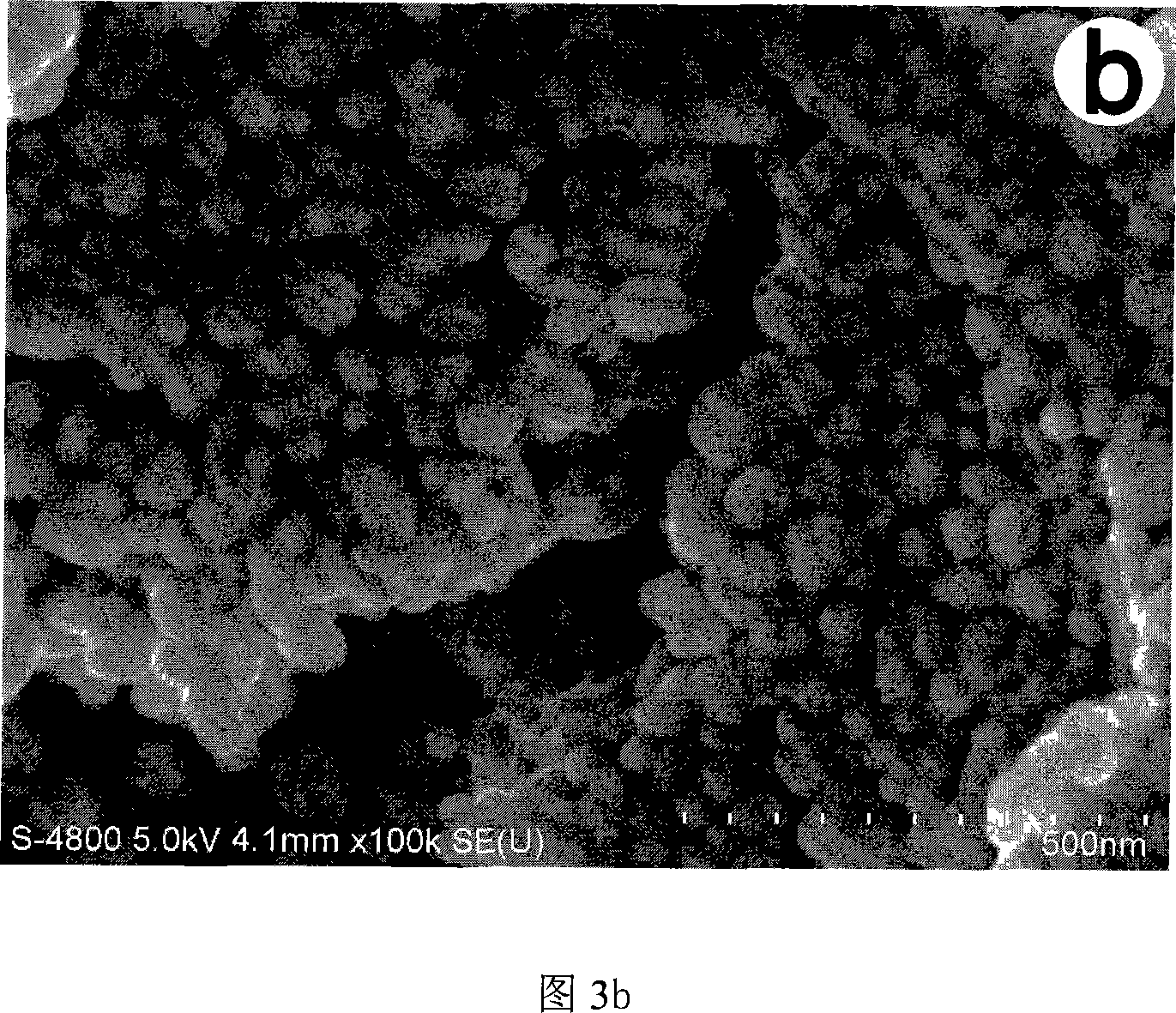

[0028] As shown in Figure 1, 10 grams of silver nitrate (AgNO 3 ) and 1208 grams of magnesium nitrate {Mg(NO 3 ) 2} The raw material was dissolved in 10962 ml of distilled water, sprayed and pyrolyzed in an air atmosphere at 600°C, the flow rate of the solution was 336 ml / hour, and the flow rate of the carrier gas was 0.28 MPa to make a composite precursor powder of silver and magnesium oxide, which was placed in the solution In 100 milliliters of absolute ethanol solutions with 1 gram of protective agent and dispersant polyvinylpyrrolidone, adopt ultrasonic dispersion for 10 minutes (stirring with a magnetic stirrer) to obtain a mixture; prepare a hydrochloric acid solution with a mass concentration of 5%, and add it dropwise to the mixture During the process, adjust the pH value to 3; after the dropwise addition, after the powder in the solution was suction filtered, after 2 washings with absolute ethanol and vacuum drying, the temperature of the vacuum drying was controlle...

Embodiment 2

[0031] 50 g of silver nitrate (AgNO 3 ) and 302 grams of magnesium nitrate {Mg(NO 3 ) 2} The raw material was dissolved in 528 ml of distilled water, sprayed and pyrolyzed in an air atmosphere at 800°C, the flow rate of the solution was 500 ml / hour, and the flow rate of the carrier gas was 0.32 MPa to make a composite precursor powder of silver and magnesium oxide, which was placed in the solution In 100 milliliters of dehydrated ethanol solutions of 5 grams of protective agent and dispersant polyvinylpyrrolidone, adopt ultrasonic dispersion for 30 minutes (using magnetic stirrer to stir), obtain mixture; Configuration mass concentration is 15% sulfuric acid solution, add dropwise to mixture During the process, adjust the pH value to 3; after the dropwise addition, after the powder in the solution was suction filtered, after washing 3 times with absolute ethanol and vacuum drying, the temperature of the vacuum drying was controlled at 70°C to obtain spherical nano-silver powd...

Embodiment 3

[0033] 50 g of silver nitrate (AgNO 3 ) and 3424 grams of nickel nitrate {Ni(NO 3 ) 2} The raw material was dissolved in 13896 ml of distilled water, sprayed and pyrolyzed in an air atmosphere at 800°C, the flow rate of the solution was 500 ml / hour, and the flow rate of the carrier gas was 0.32 MPa to make a composite precursor powder of silver and nickel oxide, which was placed in the solution In 100 milliliters of absolute ethanol solutions of 5 grams of protective agent and dispersant polyvinylpyrrolidone, adopt ultrasonic dispersion for 30 minutes (stirring with a magnetic stirrer) to obtain a mixture; configure a mass concentration of 10% ammonium chloride solution, add dropwise into the mixture, and adjust the pH value to 4; after the dropwise addition, the powder in the solution is suction-filtered, washed with absolute ethanol three times, and vacuum-dried, and the temperature of the vacuum-drying is controlled at 70°C to obtain spherical nano-silver powder (Particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com