Bone plate with sustained-release antimicrobial peptide

The technology of bone plate and antibacterial peptide is applied in the field of slow release bone plate loaded with antibacterial peptide and its manufacturing field, which can solve the problems that antibiotics are difficult to achieve effective antibacterial concentration, induce bacterial resistance, difficult to traumatic osteomyelitis and anti-infective effect, etc. Strong anti-infective bacterial biofilm formation, inhibition of bacterial biofilm formation, and improved efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

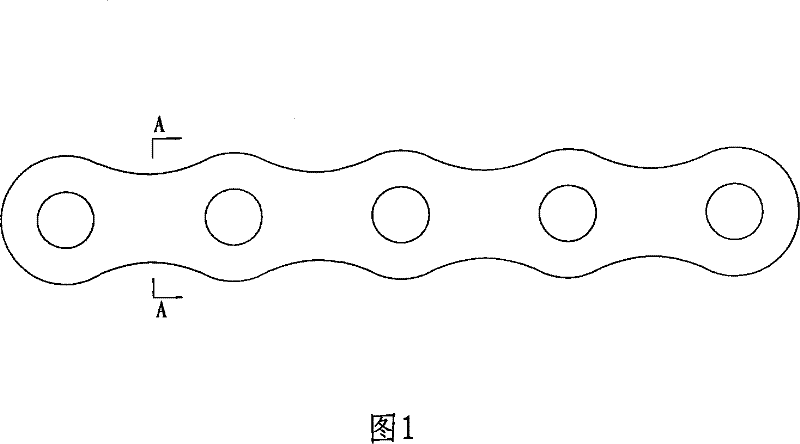

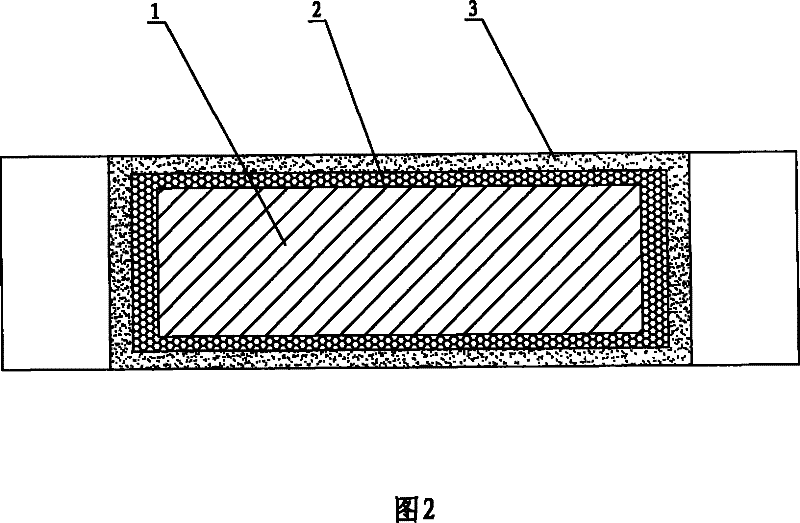

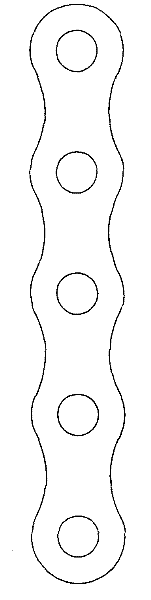

Image

Examples

Embodiment 1

[0016] Carry the manufacture method of antimicrobial peptide slow-release bone plate, carry out as follows:

[0017] Step 1, pretreatment of the surface of the titanium metal bone plate. The titanium metal bone plate was ultrasonically cleaned with distilled water, acetone, 75% ethanol, and distilled water for 10 minutes each. After taking it out, it was washed with deionized water and placed in 18wt with a volume ratio of 1:1. %HCl and 48wt%H 2 SO 4 20 minutes in the formed acid solution, take it out and wash it with deionized water, then place it in 2M NaOH solution, heat it at 50°C for 12 hours, then wash it with deionized water, and then put it in a Maofu furnace to heat at 600°C 1 hour;

[0018] Step 2, pre-coating hydroxyapatite coating 2, put the titanium or titanium alloy bone plate treated in step 1 into a mixture of NaCl: 733.5mM; CaCl 2 .2H 2 O: 12.5mM; Na 2 HPO 4 .2H 2 O: 5mM; NaCO 3 : Add 5mM MgCl to the saturated bionic solution prepared at 21mM 2 .6H 2...

Embodiment 2

[0024] Carry the manufacture method of antimicrobial peptide slow-release bone plate, carry out as follows:

[0025] Step 1: Pretreatment of the surface of the titanium alloy bone plate. The titanium alloy bone plate was ultrasonically cleaned with distilled water, acetone, 75% ethanol, and distilled water for 15 minutes each. After taking it out, it was washed with deionized water and placed in 18wt with a volume ratio of 1:1. %HCl and 48wt%H 2 SO 4 In the acid solution formed for 30 minutes, take it out and wash it with deionized water, then place it in 8M NaOH solution, heat it at 80°C for 48 hours, then wash it with deionized water, and then put it in a Maofu furnace to heat at 600°C 2 hours;

[0026] Step 2, pre-coating hydroxyapatite coating 2, put the titanium or titanium alloy bone plate treated in step 1 into a mixture of NaCl: 733.5mM; CaCl 2 .2H 2 O: 12.5mM; Na 2HPO4.2H 2 O: 5mM; NaCO 3 : Add 10mM MgCl to the saturated bionic solution prepared at 21mM 2 .6H ...

Embodiment 3

[0032] Carry the manufacture method of antimicrobial peptide slow-release bone plate, carry out as follows:

[0033] Step 1, pretreatment of the surface of the titanium metal bone plate. The titanium metal bone plate was ultrasonically cleaned with distilled water, acetone, 75% ethanol, and distilled water for 15 minutes each. After taking it out, it was washed with deionized water and placed in 18wt with a volume ratio of 1:1. %HCl and 48wt%H 2 SO 4 25 minutes in the formed acid solution, take it out and wash it with deionized water, then place it in 6M NaOH solution, heat it at 60°C for 30 hours, then wash it with deionized water, and then put it in a Maofu furnace to heat at 600°C 1.5 hours;

[0034] Step 2, pre-coating hydroxyapatite coating 2, put the titanium or titanium alloy bone plate treated in step 1 into a mixture of NaCl: 733.5mM; CaCl 2 .2H 2 O: 12.5mM; Na 2 HPO4.2H 2 O: 5mM; NaCO 3 : Add 7mM MgCl to the saturated bionic solution prepared at 21mM 2 .6H 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com