Oil seal and production method therefor

An oil seal and sealing lip technology, applied in the field of oil seals and their manufacturing, can solve problems such as reducing friction coefficient, reducing sealing performance and durability, and achieving the effect of low friction and enhanced tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

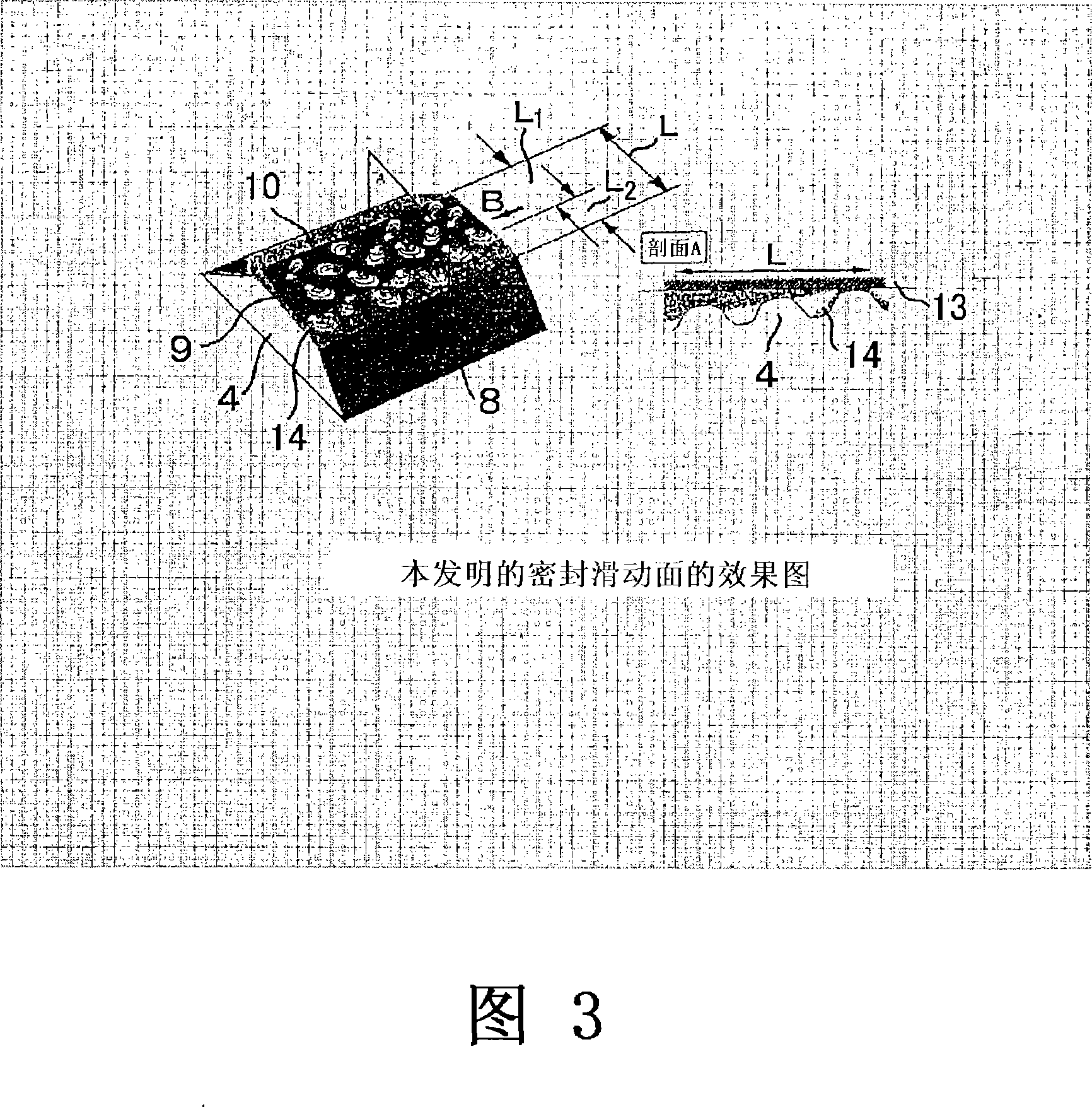

[0062] In order to avoid the deficiencies in the above-mentioned existing technology, the coating method of coating the sliding surface of the lip with a low-friction coating that has a strong bond with the base material and will not cause initial peeling due to sliding is listed below.

[0063] (1) A binder component (isocyanate-modified polybutadiene resin) that can be firmly bonded to the base material is mixed with PTFE, and a solution diluted with a solvent is used.

[0064] (2) Spray the solution shown in the above item (1) on the atmospheric side of the sliding surface of the lip before cutting.

[0065] (3) Dry and solidify by air heating.

[0066] (4) After the treatment in item (3) above, the main lip is processed by cutting.

[0067] The coated surface is formed only on the air side sliding surface through the coating agent application, heat treatment, and main lip processing steps in the above items (2) to (4).

Embodiment approach 2

[0069] A method for achieving low friction of a sealing lip in an oil seal, comprising: applying a coating solution composed of fluororesin, polyethylene resin, isocyanate-modified polybutadiene resin and a solvent to the atmosphere of the sealing lip The process of side sliding surface; the process of sintering and drying after coating; the process of forming the sealing fluid side sliding surface on the sealing lip by cutting after drying.

Embodiment approach 3

[0071] The coating film applicable to the present invention is described in detail below.

[0072] That is, for 100 parts by mass of 1,2-polybutadiene containing isocyanate groups or a 1,2-polybutadiene mixture mixed with 1,2-polybutadiene containing hydroxyl groups, A polyethylene resin and a fluororesin are mixed in a ratio of 10 to 160 parts by mass to form an organic solvent solution, and the coating agent for vulcanized rubber thus constituted is applied to the air-side slope of the lip sliding portion.

[0073] As the isocyanate group-containing 1,2-polybutadiene, one having a molecular weight of 1,000 to 3,000 to which an isocyanate group is added to a terminal group can be used. Commercially available products such as Nippon Soda Products Nippon Soda TP-1001 (solution containing 50% by weight of butyl acetate) and the like can be used as they are. This polybutadiene resin is characterized in that it has better compatibility and compatibility with rubber, better adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com