Surface treated metallic oxide fine powder and preparation and use thereof

A surface treatment and oxide technology, applied in the field of surface-treated metal oxide fine powder and surface-treated silica fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The BET specific surface area to be synthesized by the vapor phase method is 200m 2 / g of silica powder (NIHON AEROSIL product; Aerosil 200) was added to the reaction vessel and while stirring in a nitrogen atmosphere, 5 g of γ-aminopropyltriethoxysilane (Shin-Etsu Chemical Co., Ltd. product : KBE 903), N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (Shin-Etsu Chemical Co., Ltd product: KBM603) and 15 g of dimethyl-silicone oil (Shin-Etsu Chemical Co., Ltd. product: a mixed solution of KF 96) was sprayed onto 100 g of the silica powder. The sprayed powder was heated with stirring at 200° C. for 60 minutes, and then cooled to prepare a surface-treated silica fine powder A.

Embodiment 2-7

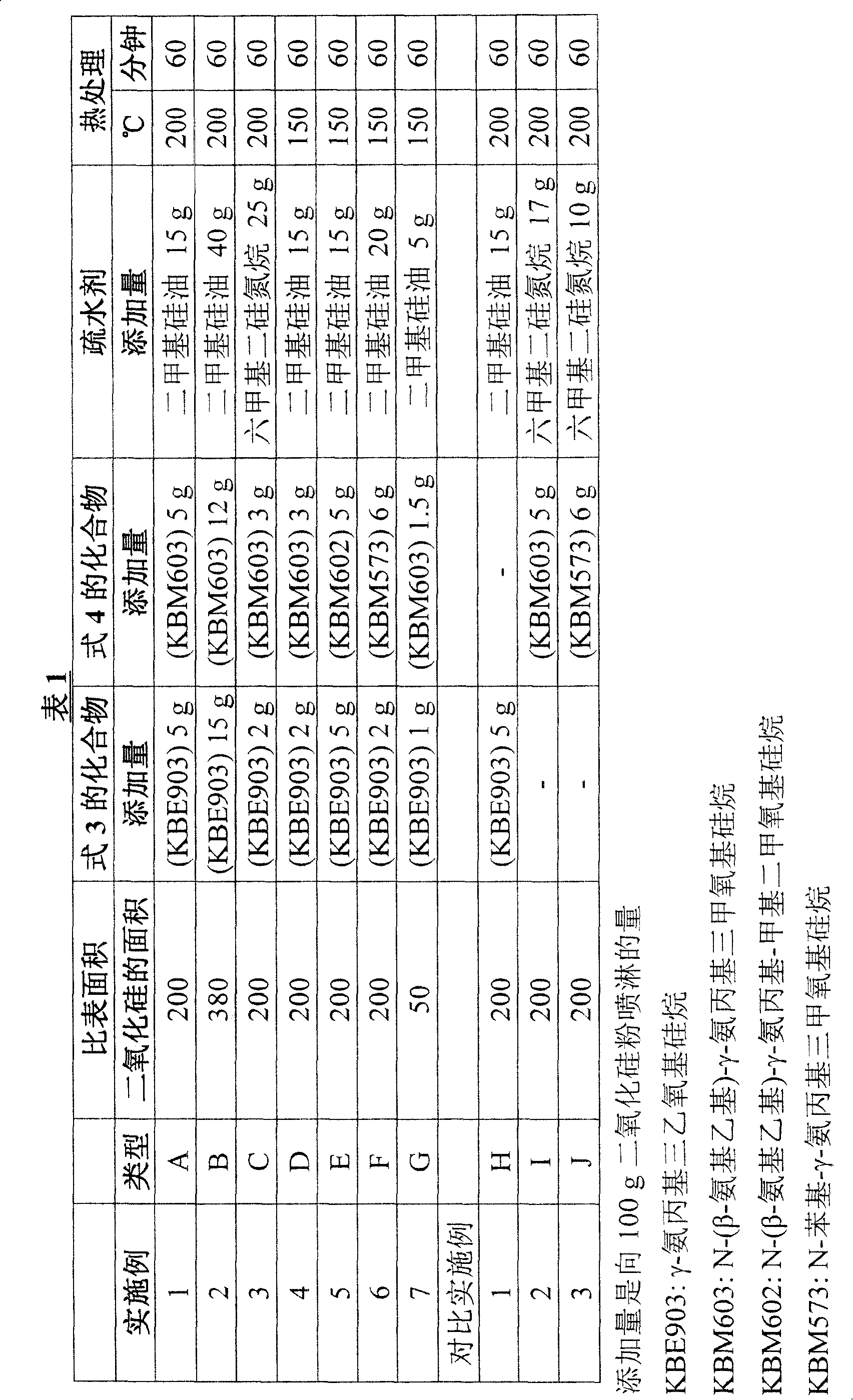

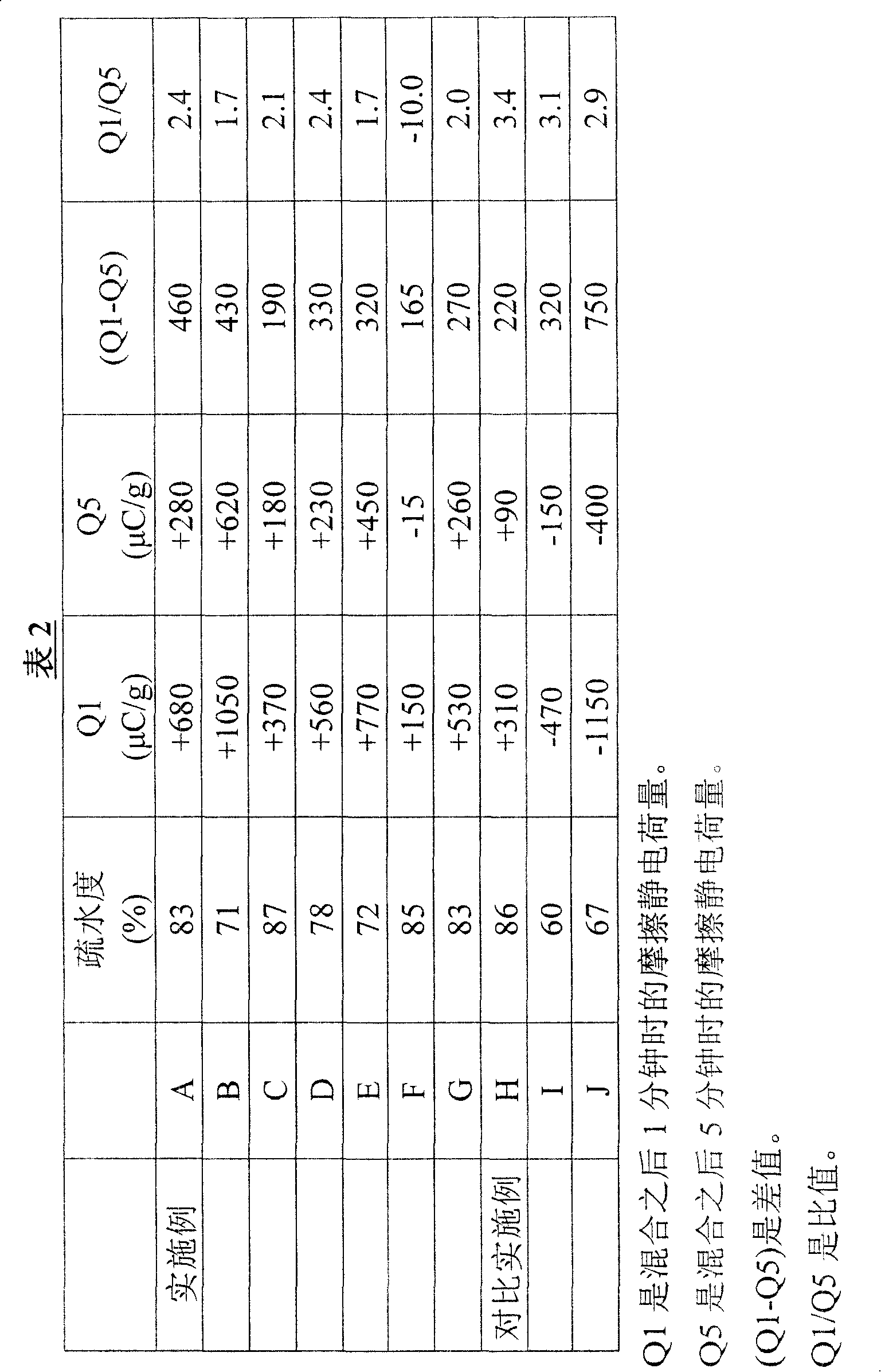

[0066] Each mixed solution is synthesized by the vapor phase method and has the silica powder with the specific surface area shown in Table 1, the primary amino-containing silane coupling agent shown in Formula 3, and the amino-containing silane coupling agent shown in Formula 4. agent and hydrophobic agent composition, the mixed solution was used to prepare surface-treated silica fine powders B-G by the same method as in Example 1 under the heating conditions shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com