Method for preparing high temperature nylon

A nylon, high-temperature technology, applied in the field of polymer material preparation, can solve the problems of difficult operation, increased thermal history, gelation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

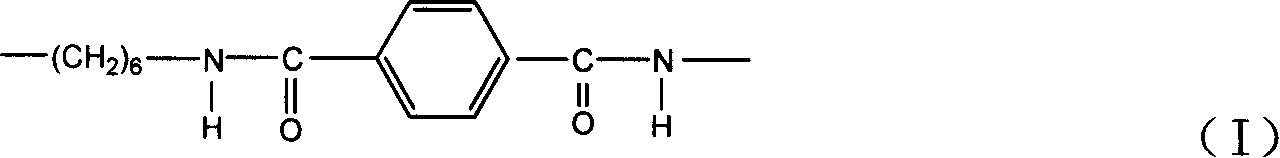

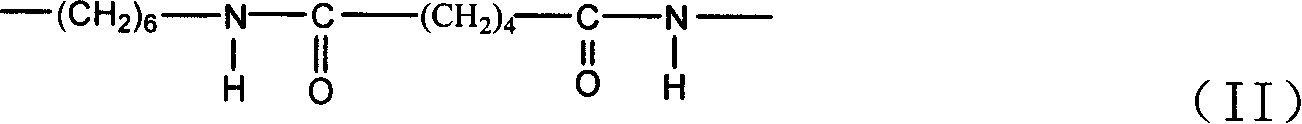

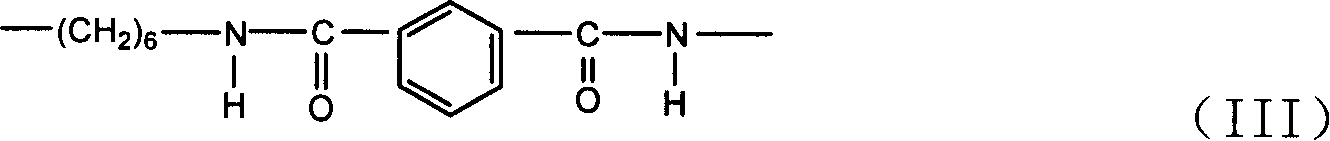

Image

Examples

preparation example Construction

[0063] Each step of the preparation method of the present invention is described in detail below:

[0064] three-step polymerization

[0065] The high temperature nylon (HPN) of the present invention is prepared by the following method.

[0066] Firstly, nylon salt is prepared at low temperature, and then the primary condensate is made under specific conditions, and then through the later solid-state polycondensation step, so as to achieve a high degree of polymerization. This is a three-step polymerization method.

[0067] For example:

[0068] (a) dissolving the aromatic dibasic acid with a content ≥ 99% in 2 to 5 times as much deionized water, heating to 60 to 130°C, preferably 80 to 100°C while stirring;

[0069] (b) dissolving the diamine in 1-3 times deionized water, and heating to 60-120°C, preferably 80-100°C while stirring;

[0070] (c) The two raw materials are injected into the mixed reaction kettle with a metering pump according to an equimolar ratio to react, t...

Embodiment 1

[0103] Add 166.13Kg of terephthalic acid into the dissolution tank, then add twice as much deionized water, and heat to 100°C while stirring. At the same time, 116.21 Kg of hexamethylenediamine was added into 1 times deionized water, and dissolved at a temperature of 80°C. Use metering pumps to send the two solutions into the mixer at the same time, and then into the neutralization tank, and control the neutralization temperature to 90°C and pH 7.1 to 7.2. The reactant enters the crystallizer and is cooled by chilled water to reduce the temperature to 25°C and form crystals. The material was put into a centrifuge, and 266.25Kg of wet nylon 6T salt was obtained after separation, with a yield of 94.3% and a water content of 13.6%. The melting point of nylon salt is 284.9°C, the content of free acid is 0.15%, and the content of free amine is 0.21%.

[0104] Add 3150g of terephthalic acid and hexamethylenediamine salt, 2100g of hexamethylene diammonium adipate (66 salt), 20g of ...

Embodiment 2

[0108] The salt that 3250g terephthalic acid and hexamethylenediamine form, 2100g hexamethylene diammonium adipate (66 salts), 40g acetic acid, 5g sodium hypophosphite monohydrate and 2.5 liters of distilled water are added to a 20L polymerization kettle, and then according to Example 1 The heating operation was performed to obtain a prepolymer having an intrinsic viscosity of 0.14 dl / g and a molecular weight distribution of 5.3. The prepolymer was dried under reduced pressure at 100° C. for 12 hours, and pulverized into particles having a particle diameter of not more than 2 mm. The particles were subjected to solid-state polymerization at 230° C. and a pressure of -0.1 MPa for 4 hours to obtain white high-temperature nylon (HPN) with an intrinsic viscosity [η] of 1.14 dl / g, a molecular weight distribution of 1.9, and a crystallization enthalpy of 62.24 J / g, heat distortion temperature is 157°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com