Absorption processing system of volatile organic compounds

A technology of volatile organic compounds and volatile organic compounds, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, and can solve problems such as waste, derivative pollutants, activated carbon, and ozone layer destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

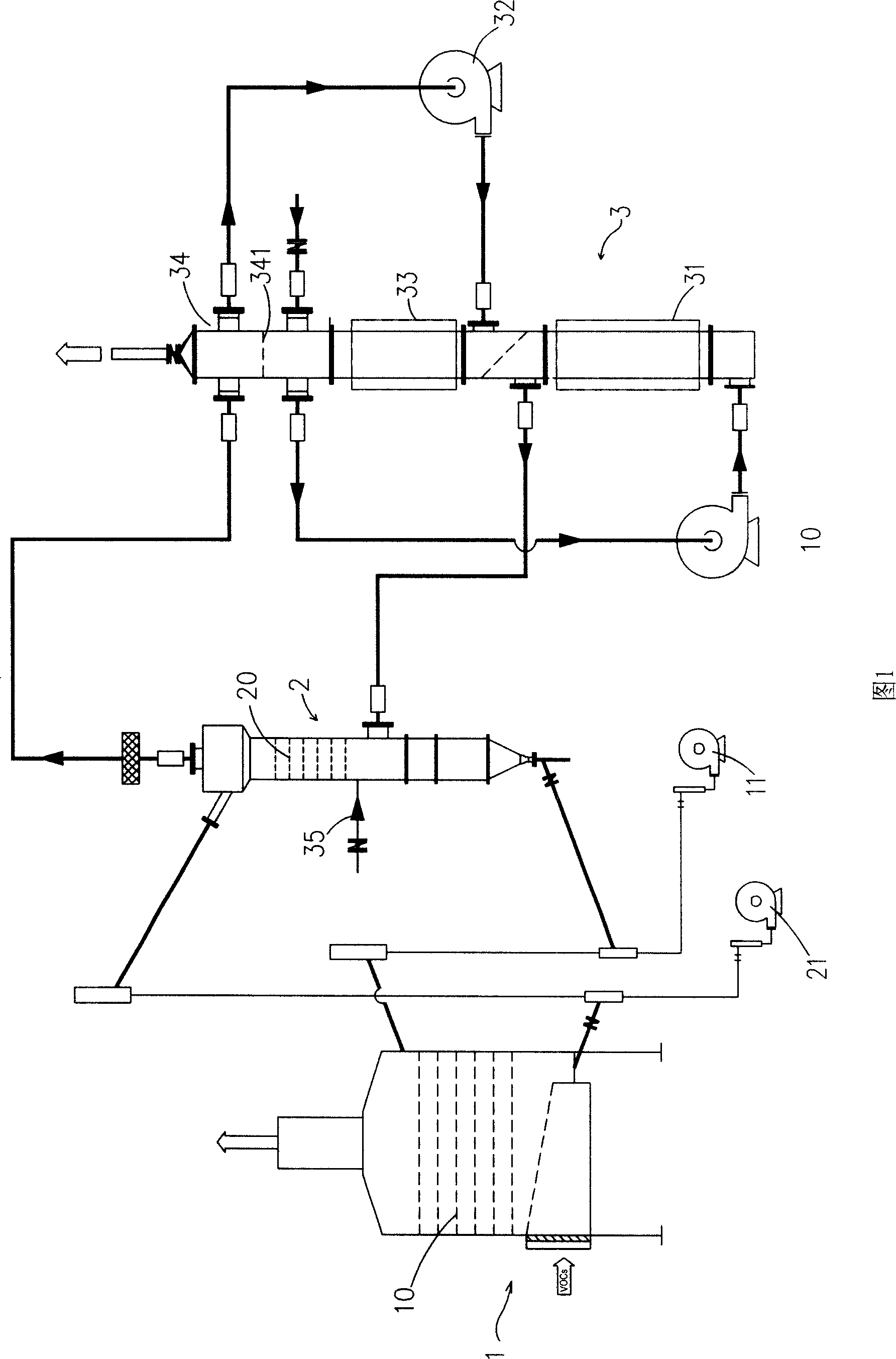

[0014] Please refer to Figure 1, which is a preferred embodiment of the volatile organic waste gas adsorption treatment system of the present invention, that is, a system diagram of activated carbon regeneration and heat recovery, and its composition at least includes:

[0015] The fluidized adsorption bed 1, mainly utilizes the large specific surface area of activated carbon (100-1000m2 / g), produces large-area flow and increases the adsorption effect to meet the regulations and standards of clean air; as shown in the figure, the VOC waste gas is fluidized After the bottom side of the adsorption bed 1 is fed in, the VOC pollutants are adsorbed and removed by the adsorption of the evenly distributed bead-like activated carbon in the series of punching plates 10 above, and the air after the purification of VOC is removed from the fluidized adsorption bed 1 Discharge from the top. When the activated carbon adsorbs a large amount of VOC pollutants, it will be discharged from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com