High concentration organic wastewater processing system

A technology of organic waste water and treatment system, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the difficulties of effluent recovery, utilization and monitoring, and high operating costs , Large footprint and other issues, to achieve good capillary wettability, reduce organic load, and reduce COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

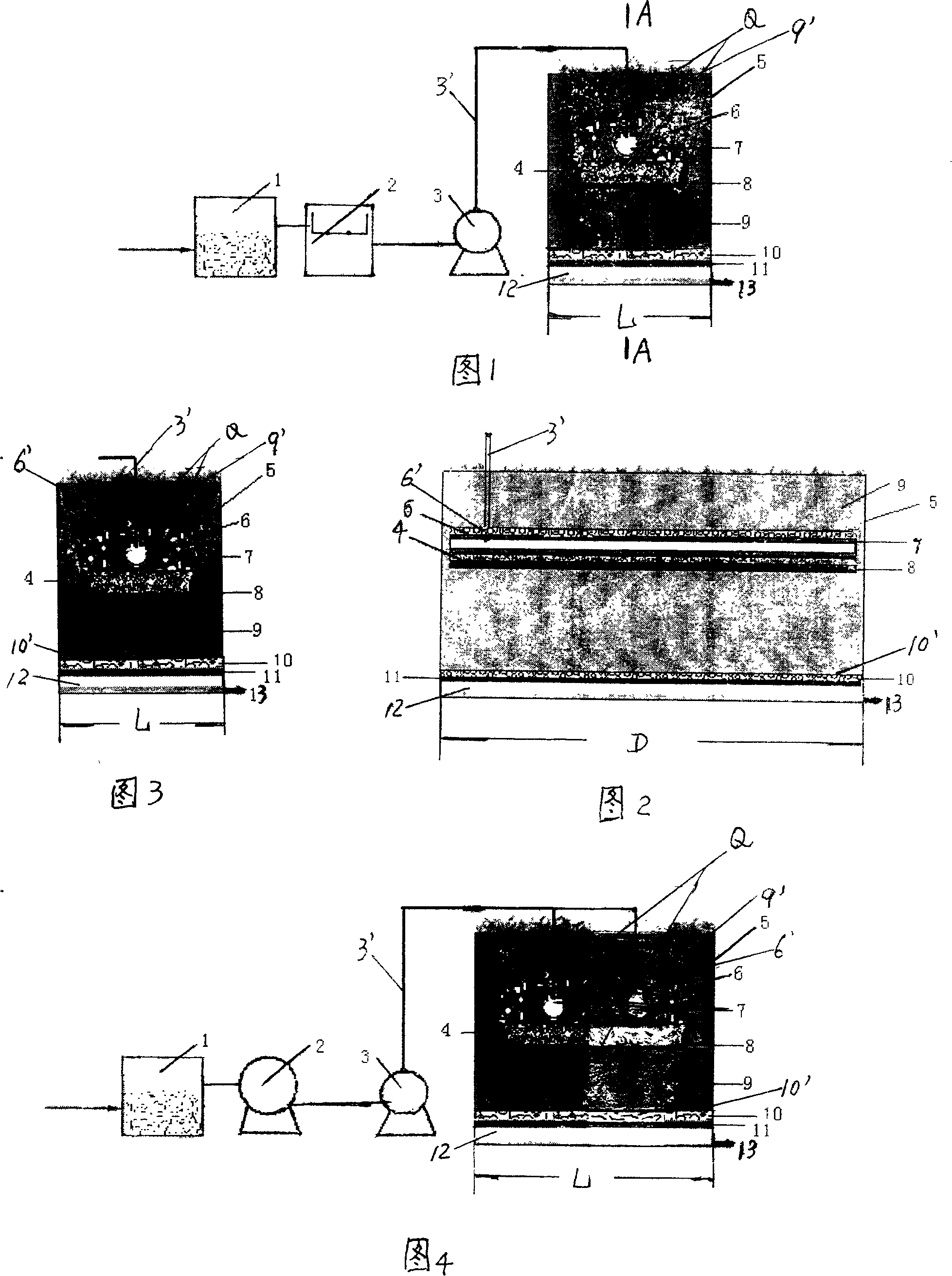

[0015] Embodiment 1: The treatment system of the high-concentration organic wastewater includes a flocculation sedimentation tank 1 , a filter tank 2 connected with it, and a soil infiltration device connected with the filter tank 2 .

[0016] The soil infiltration device comprises that the outside is built with bricks, and the inner surface is sealed with cement shell 5. The inner cavity of the shell 5 is a cuboid. Its width L is 50 cm, and its thickness D is 150 cm. The bottom of the inner cavity is a clear water tank 12. There is a water outlet 13 at its end, and the top of the clear water tank 12 is a load-bearing water-permeable layer 11 made of bamboo fence. The distance between the load-bearing water-permeable layer 11 and the inner bottom surface of the housing 5 is 10-15cm. A 10-13cm thick gravel layer 10 is laid on it, and a prepared soil layer 9 is arranged on it; an isolation layer 10' is arranged between the gravel layer 10 and the prepared soil layer 9, and the is...

Embodiment 2

[0018] Embodiment 2: the housing 5 inner cavity of the soil infiltration device of the treatment system of the high-concentration organic wastewater in the present embodiment is cuboid, and its wide L is 100cm, and thickness is 180cm, and the load-bearing water-permeable layer 11 is apart from housing 5 The distance of the inner bottom surface is 16-19cm, and an 18cm-thick gravel layer 10 is laid on the load-bearing water-permeable layer 11; the isolation layer 10' between the gravel layer 10 and the prepared soil layer 9 is a kind of pore size of 1-1.5 cm. The glass fiber fabric of mm gap; The purification device in the middle and upper part of the prepared soil layer is also an inverted trapezoidal purification ditch Q, the lengths of its upper bottom and lower bottom are respectively 70cm, 45cm, and the height is 50cm. The bottom of the purification ditch Q It is a gravity anti-seepage layer 8 made of glass fiber reinforced plastic material. The gravity anti-seepage layer 8 ...

Embodiment 3

[0020] Embodiment 3: the wide L of casing 5 is 80cm in the soil infiltration device of the processing system of the high-concentration organic waste water in the present embodiment, lays 14cm thick gravel layer 10 on the load-bearing water-permeable layer 11; The purification device in the prepared soil layer in the interior is a cuboid shape, the width L' is 60cm, the thickness is 180cm, and the height is 45cm. The bottom of the purification device is made of hard plastic material, and the gravity anti-seepage layer 8 is filled with 12cm thick sand, in the filter pool 2 in the present embodiment is provided with a filter screen.

[0021] The porosity of the prepared soil layer 9 in the soil infiltration device and the special soil 9' in the purification device is 56%, the saturated hydraulic conductivity of the soil is 100cm / d, and the soil organic matter is 16%. This prepared soil is made by adding peat soil and sawdust to the soil. Other structures and materials in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com