Hydrogen permeable film and fuel battery using the same

A fuel cell and permeable membrane technology, applied in fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve problems such as hydrogen permeability decline, reduce the decline of electromotive force with time, high hydrogen permeability, high hydrogen permeability, etc. The effect of less deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

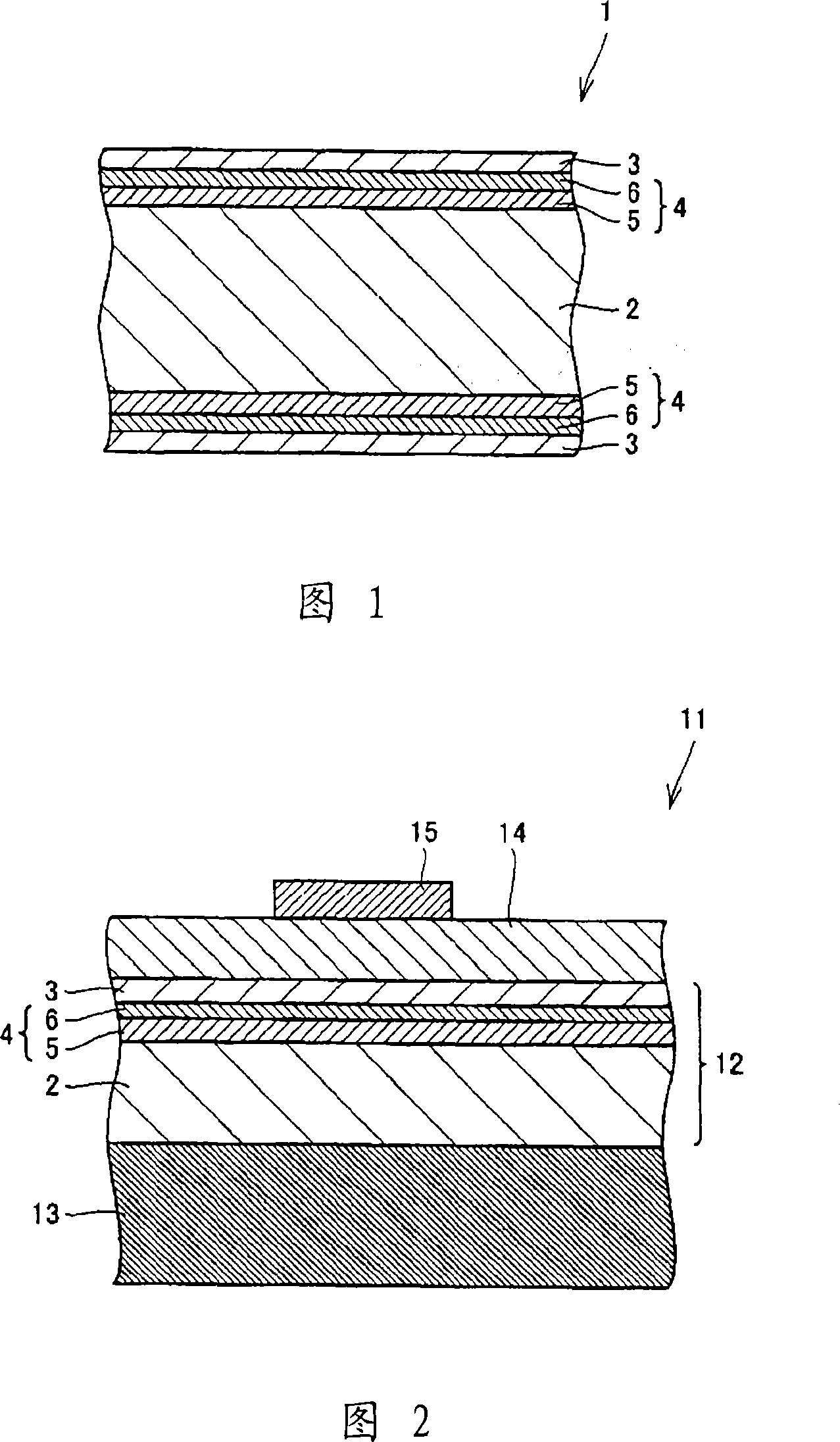

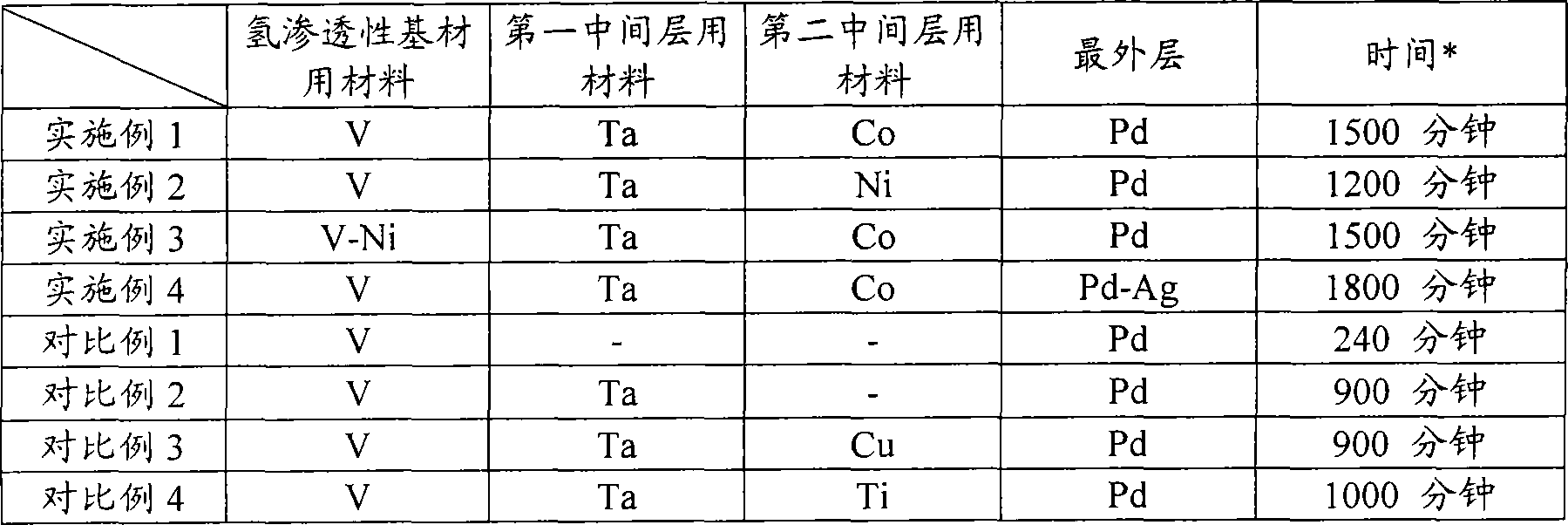

[0062] A commercially available V-foil (disc shape with a diameter of 10 mm and a thickness of 100 μm) with a thickness of 0.1 mm was used as the hydrogen permeable substrate 2, and the vacuum degree was not greater than 2×10 -3 Both surfaces of the V foil were covered with Ta by vapor deposition under Pa and without heating the substrate to form a Ta layer (first intermediate layer 5 ) with a thickness of 0.03 μm (30 nm). Then, similarly, the surface of each Ta layer was covered with Co to form a Co layer (second intermediate layer 6 ) having a thickness of 0.03 μm (30 nm). In addition, similarly, the surface of each Co layer was covered with Pd to form a Pd film 3 with a thickness of 0.1 μm on the outermost layer. Thus, the hydrogen permeable membrane 1 of the example shown in Fig. 1 was produced.

[0063] With respect to the obtained disc-shaped hydrogen permeable membrane 1 having a diameter of 10 mm, the amount of hydrogen permeation per unit time was measured under the ...

Embodiment 2

[0065] Hydrogen permeable membrane 1 was produced in the same manner as in Example 1 except that Ni was used instead of Co to form second intermediate layer 6 . The measurement was performed in the same manner as in Example 1 and it was found that the hydrogen permeation amount decreased by 30% from the initial hydrogen permeation amount at 1200 minutes after the start of the measurement.

Embodiment 3

[0067] A hydrogen permeable membrane 1 was produced in the same manner as in Example 1 except that a commercially available V-Ni foil (disc shape with a diameter of 10 mm and a thickness of 100 μm) with a thickness of 0.1 mm was used as a hydrogen permeable substrate 2 . The measurement was performed in the same manner as in Example 1 and it was found that the hydrogen permeation amount decreased by 30% from the initial hydrogen permeation amount at 1500 minutes after the start of the measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com