Low-temperature solid-phase synthesizing method for hexagonal-phase nickel sulfide submicron crystal

A nickel submicron, solid-phase synthesis technology, applied in the direction of nickel sulfide, etc., can solve the problems of difficult industrialization of products, difficult organic solvent treatment, difficult separation of microemulsions, etc., and achieve excellent optics, low cost, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. According to a certain molar ratio of 1:1, respectively weigh 1.2442g (0.005mol) of nickel acetate and 0.3806g (0.005mol) of thiourea after grinding for 10 minutes, and put the two into a crucible to stir and mix evenly.

[0021] 2. Put the crucible containing the raw materials in a muffle furnace, react at 350°C for 3 hours, turn off the power, stop heating, and let it cool down to room temperature naturally.

[0022] 3. After grinding the cooled product, a black powdery hexagonal nickel sulfide submicron crystal is obtained.

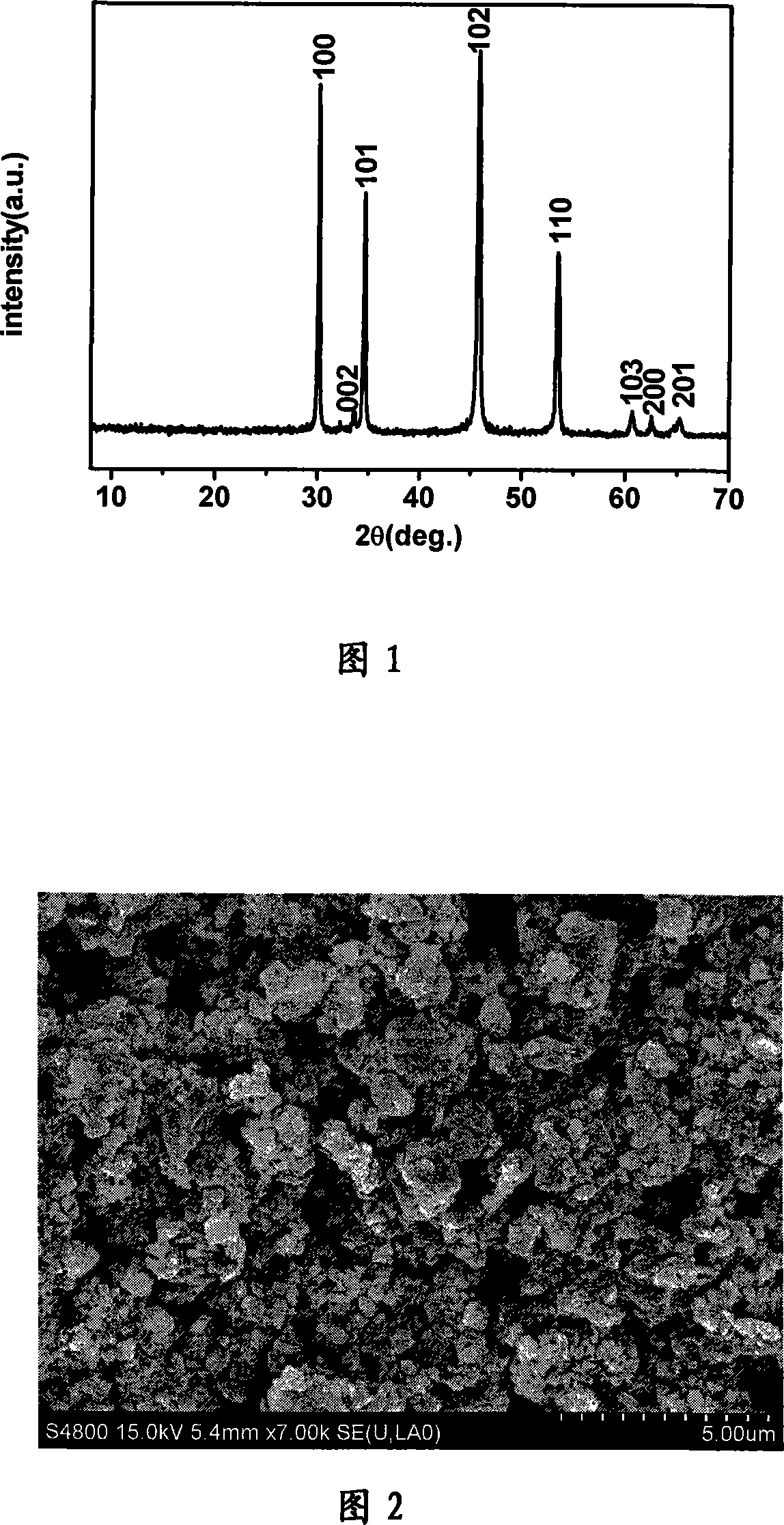

[0023] As shown in Figure 1 and Figure 2, the structure and phase identification of the product was carried out using a German Bruker AXS D8 ADVANCEX-ray powder diffractometer (XRD, Cu K α radiation, λ=1.54056 Ȧ, 40kV, 200mA) for measurement. The morphology and size of the product were observed with a field emission scanning electron microscope (FESEM, 15kV) of S-4800 from Hitachi, Japan.

[0024] The results showed that:

[0025] Fig. 1: ...

Embodiment 2

[0028] 1. According to a certain molar ratio of 1:1, respectively weigh 1.2442g (0.005mol) of nickel acetate and 0.3806g (0.005mol) of thiourea after grinding for 10 minutes, and put the two into a crucible to stir and mix evenly.

[0029] 2. Put the crucible containing the raw materials in a muffle furnace, react at 400°C for 3 hours, turn off the power, stop heating, and let it cool down to room temperature naturally.

[0030] 3. After grinding the cooled product, a black powdery hexagonal nickel sulfide submicron crystal is obtained.

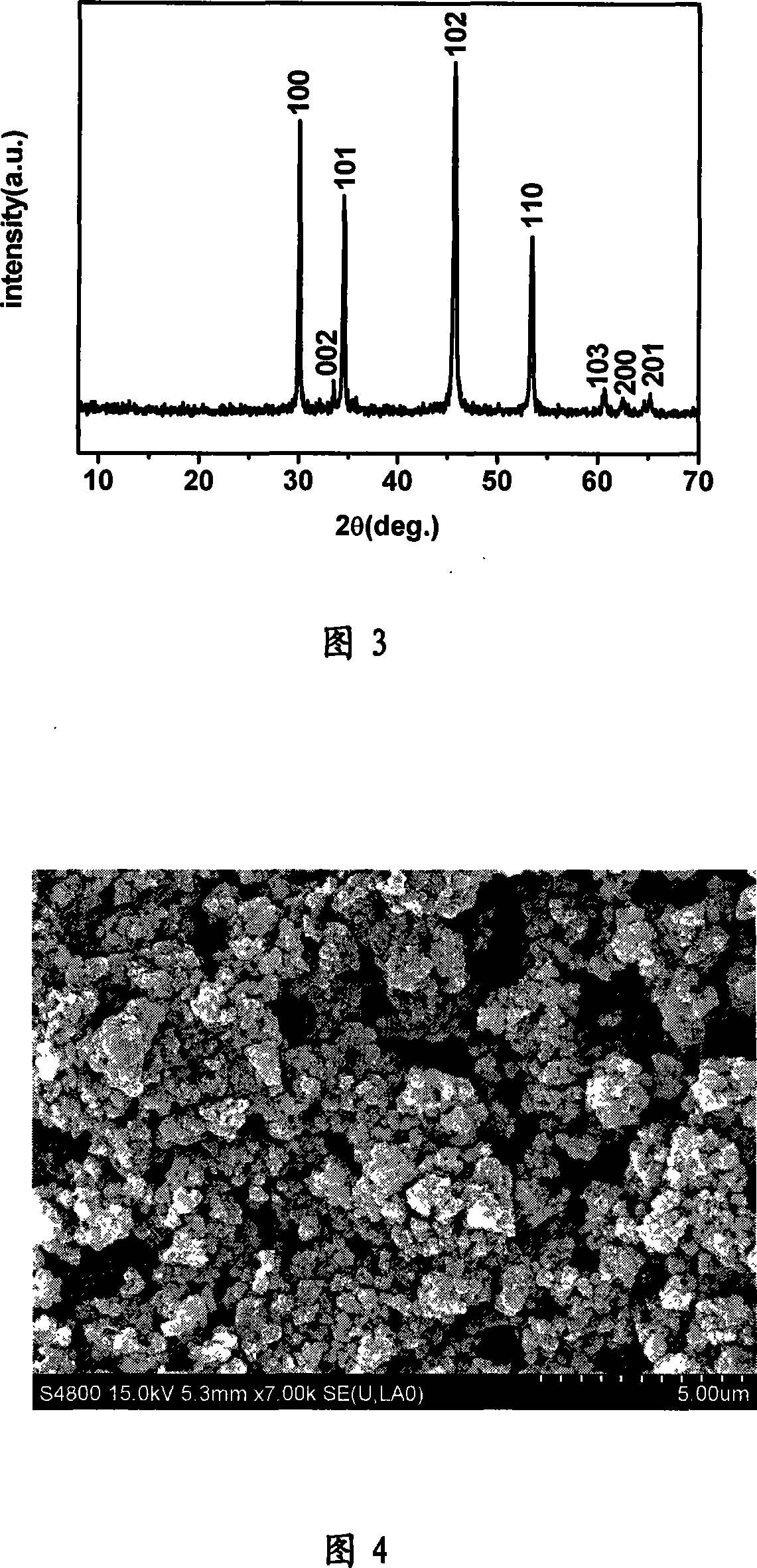

[0031] As shown in Figure 3 and Figure 4, the structure and phase identification of the product adopts German Bruker AXS D8 ADVANCEX-ray powder diffractometer (XRD, Cu K α radiation, λ=1.54056 Ȧ, 40kV, 200mA) for measurement. The morphology and size of the product were observed with a field emission scanning electron microscope (FESEM, 15kV) of S-4800 from Hitachi, Japan.

[0032] The results showed that:

[0033] Fig. 3: X-ray diffraction...

Embodiment 3

[0036] 1. According to a certain molar ratio of 1:1.5, respectively weigh 1.2442g (0.005mol) of nickel acetate and 0.5709g (0.0075mol) of thiourea after grinding for 10 minutes, and put the two into a crucible to stir and mix evenly.

[0037] 2. Put the crucible containing the raw materials in a muffle furnace, react at 400°C for 3 hours, turn off the power, stop heating, and let it cool down to room temperature naturally.

[0038] 3. After grinding the cooled product, a black powdery hexagonal nickel sulfide submicron crystal is obtained.

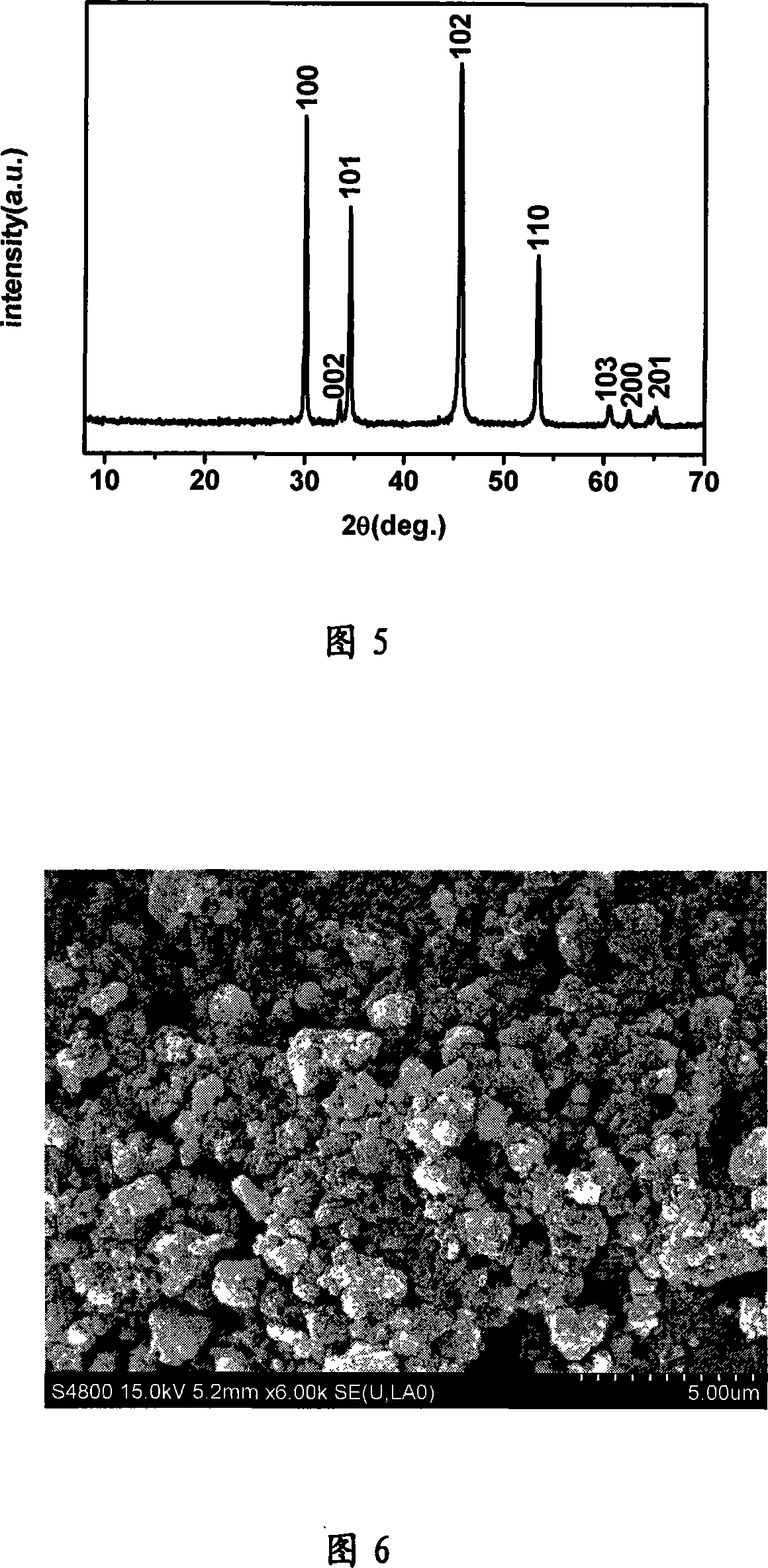

[0039] As shown in Figure 5 and Figure 6, the structure and phase identification of the product adopt German Bruker AXS D8 ADVANCEX-ray powder diffractometer (XRD, Cu K α radiation, λ=1.54056 Ȧ, 40kV, 200mA) for measurement. The morphology and size of the product were observed with a field emission scanning electron microscope (FESEM, 15kV) of S-4800 from Hitachi, Japan.

[0040] The results showed that:

[0041]Figure 5: X-ray diffract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com