Non-conducting material electric spark milling method

A non-conductive material and electric spark technology, applied in the field of mechanical processing, can solve the problems of high cost and low processing efficiency, and achieve the effect of convenient processing and avoiding poor processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

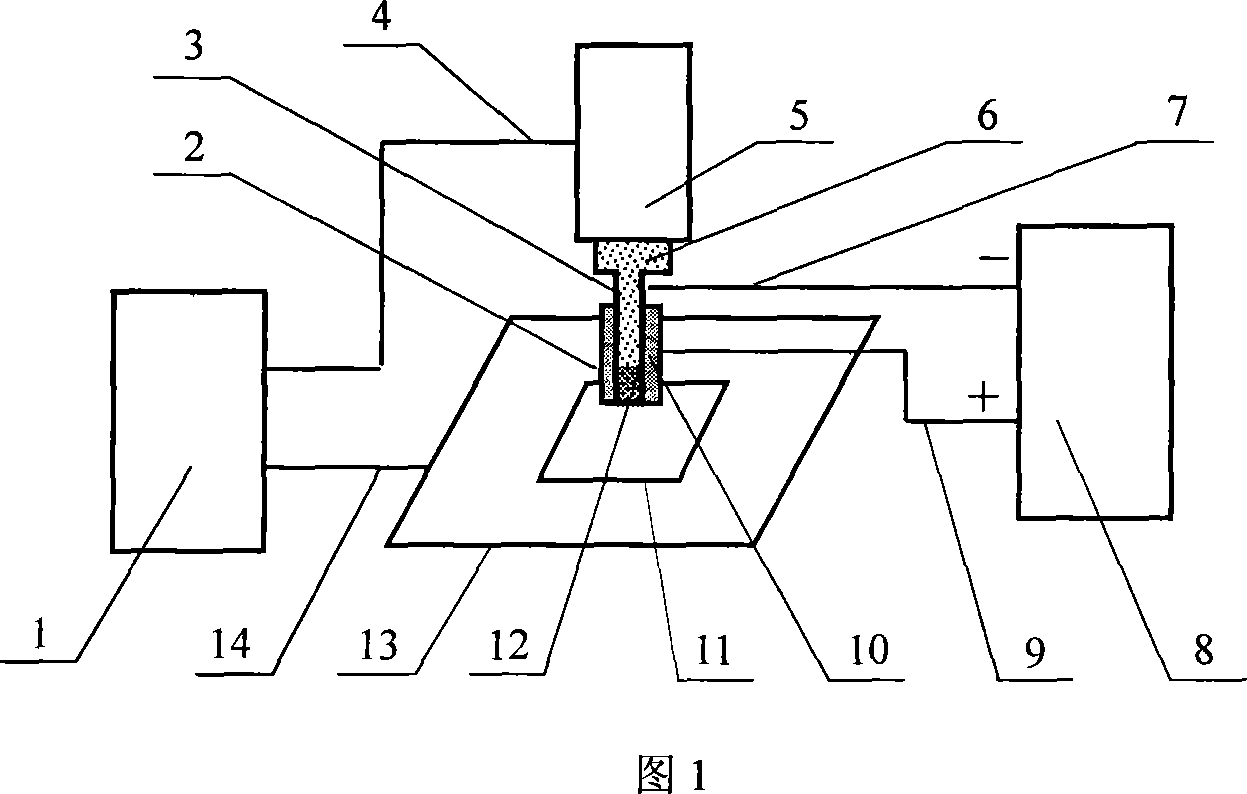

[0014] See Figure 1. In the system composition diagram of the electric spark milling method for non-conductive materials of the present invention, 1 is a digital control system, which is mainly used for the control of speed, displacement and processing parameters, etc.; The sleeve is installed on the negative tool electrode, which can rotate and move in the Z direction with the negative tool electrode; 3 is the negative tool electrode, which is connected to the negative pole of the pulse power supply and is installed on the spindle head, which can rotate with the spindle head and the movement in the Z direction; 4 is the wire connecting the CNC system and the spindle DC servo motor, providing a detection and control circuit for the DC servo motor; 5 is the spindle system, which is equipped with a spindle head, which can drive the spindle head to move in the Z direction. The servo motor and the DC motor that can drive the spindle to rotate. Under the control of the servo contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com