Combined hybrid cross-linked dynamic polymer and application thereof

A hybrid cross-linking and polymer technology, applied in the field of combined hybrid cross-linking dynamic polymers, can solve problems such as difficulty in synergistic orthogonal comprehensive performance, limited dynamic effect and dynamic regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0420] In the preparation process of dynamic polymer foam materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0421] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0422] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under press...

Embodiment 1

[0445] Using dicumyl peroxide as an initiator, graft-modified low-molecular-weight polypropylene with maleic anhydride through melt grafting reaction to obtain graft-modified polypropylene, wherein the mass of dicumyl peroxide and maleic anhydride The ratio is 1:10.

[0446] Use equimolar amounts of 2-aminoethylaminoboronic acid and 2-(4-aminobutyl)propane-1,3-diol as raw materials, tetrahydrofuran as a solvent, and carry out condensation reaction at 50°C and pH=8 Amino compound (a) is obtained.

[0447] Weigh 25g of grafted modified polypropylene and 20mg of BHT antioxidant, add them into a dry and clean three-necked flask, heat to 160°C under nitrogen protection conditions to stir and melt, then add 2.0g of diamino compound (a), 1.5g bis(2-hydroxy)ethyl tetrasulfide (b), 1.8g 2,2'-diselenidethanol (c), 0.15g p-toluenesulfonic acid, 2.0g plasticizer DOP, 0.25g dimethyl The silicone oil continued to react under nitrogen for 3h. Then it was poured into a suitable mold, molde...

Embodiment 2

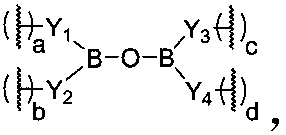

[0450] Using dicumyl peroxide as an initiator, graft-modified low-molecular-weight polyethylene with maleic anhydride through melt grafting reaction to obtain graft-modified polyethylene, wherein the mass of dicumyl peroxide and maleic anhydride The ratio is 1:10; then p-toluenesulfonic acid is used as a catalyst and 1-aminoethylboronic acid is used to obtain boric acid graft modified polymer (a) through melt grafting reaction.

[0451]

[0452] Get 20g boric acid graft modified polyethylene (a), 5g ethylene-vinyl alcohol copolymer, 3g dioctyl phthalate, 1.5g dithiocarbamic acid N-aminoethyl-S-aminoethyl ester ( b), 1.2g stearic acid, 1.2g tribasic basic lead sulfate, 0.5g di-n-butyltin dilaurate, 0.1g antioxidant 168, 0.2g antioxidant 1010, 0.2g photoinitiator DMPA, 0.25 After mixing 1 g of simethicone oil evenly, add it to a small internal mixer and knead for 10 minutes, then add 5 g of carbon fiber and continue kneading. After the kneading is completed, take out the kneade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com