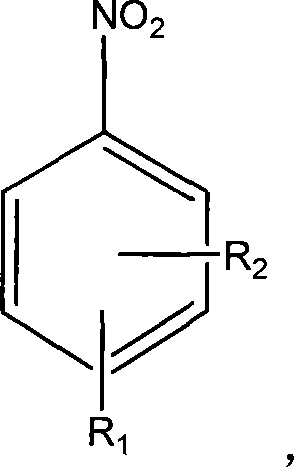

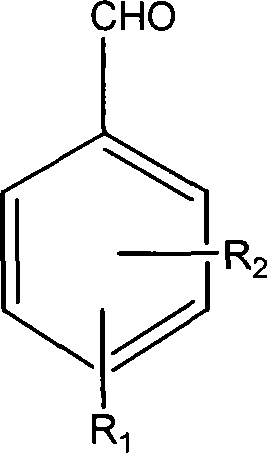

Method for preparing aromatic amine, alcohol and alkane by heterogeneous catalytic hydrogen transfer

An aromatic amine, catalytic hydrogen technology, applied in the chemical industry, can solve the problems of poor selectivity, limited selectivity improvement, narrow application range, etc., and achieve the effects of environmental friendliness, good selectivity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

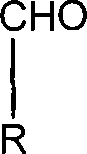

Method used

Image

Examples

Embodiment 1

[0032] 54.8mg of nitrotoluene, 4mg of potassium carbonate, 0.05g of 1.5%wtAu / ZrO were charged into a stainless steel autoclave with a capacity of 100ml 2 Catalyst, 20ml of isopropanol, and after purging the autoclave with nitrogen, the internal temperature of the autoclave was raised to 90°C, 0.5MPa inert gas was introduced, stirred for 3h, and the temperature in the autoclave was cooled to room temperature. Then centrifuge, analyze the result with gas chromatography, the conversion rate that p-bromonitrobenzene is converted into p-bromoaniline is 99.8%, and the selectivity is 97.7%.

Embodiment 2~4

[0034] Each embodiment repeats the process of Example 1 by the contents of each component specified in Table 1. Among them, 20ml of isopropanol is used as the hydrogen donor, and 0.05g of 1.5%wt Au / ZrO is used as the catalyst 2 Reminder, pressure 0.5Mpa, not given in the table below.

[0035] The results are listed in Table 1 below.

[0036] Table 1

[0037] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com