Method for producing highly-effective compound polysilicate aluminum and ferric flocculant by coal ash and kaolinite

A technology of polyaluminum iron silicate and kaolin, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of process equipment investment cost, high production operation cost, high waste water treatment cost, harsh preparation conditions, etc., and achieve clean water Excellent effect, fast precipitation, good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

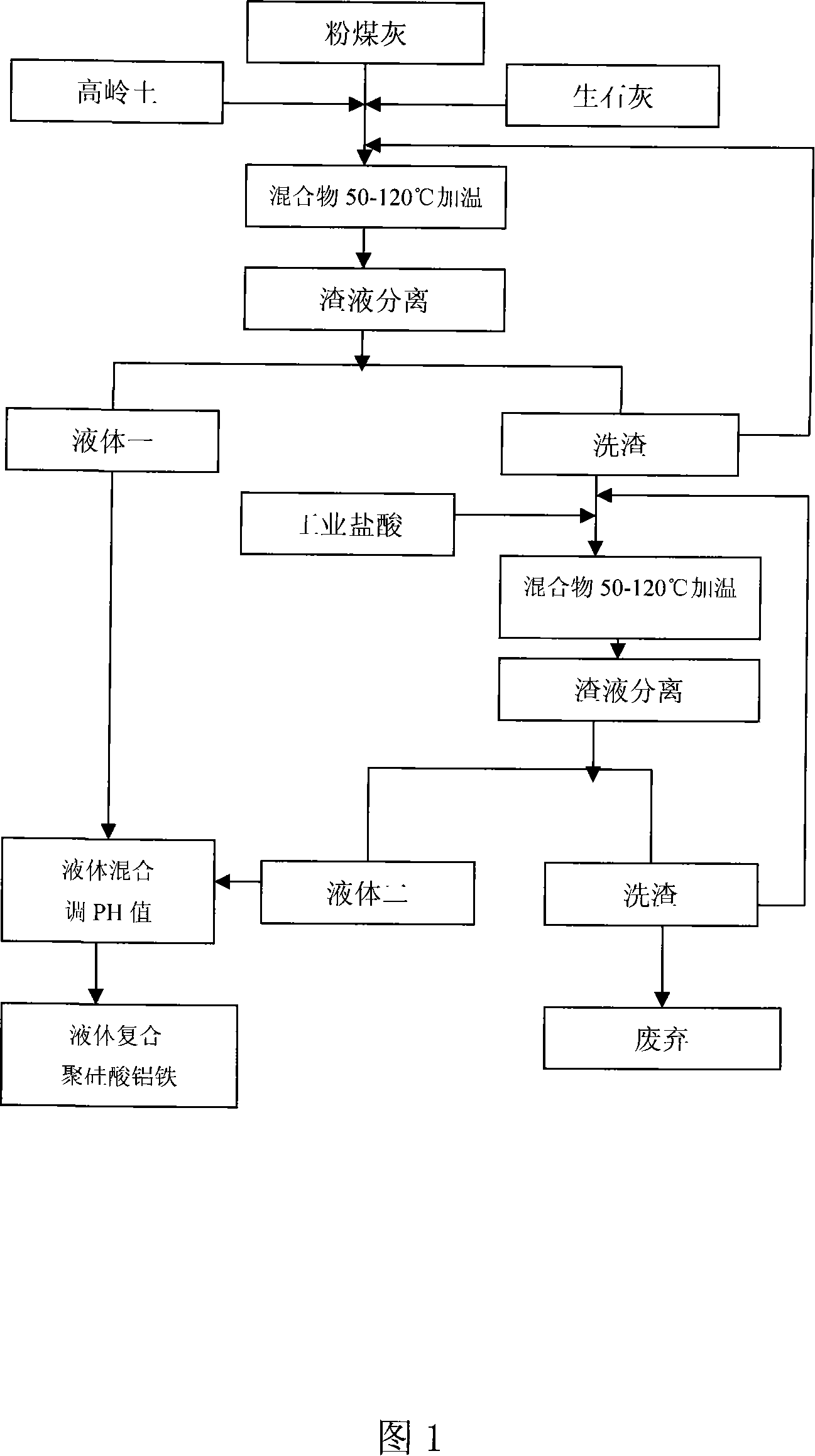

[0031] Example 1: Mix 500 kilograms of fly ash, 500 kilograms of kaolin and 20 kilograms of quicklime, feed into the reactor, add water to keep the liquid-solid volume ratio at 1:1, stir and soak, and heat at 100°C for 6 hours Finally, after cooling, carry out residue-liquid separation, and adjust the pH of the filtrate to about 9 for preservation; wash the filter residue, and the residue washing water can be recycled for secondary use, and then the filter residue is mixed with 36.7% industrial hydrochloric acid to keep the liquid-solid volume ratio at 1:1. Stir and soak in a reaction kettle, heat at 80°C for 5 hours, and separate residue from liquid after cooling to obtain a filtrate. Mix the two filtrates 1:1, stir, adjust the pH value to about 4, and let it stand still to obtain the brown-red high-efficiency composite polyaluminum iron silicate (PAFSC) flocculant liquid of the present invention.

Embodiment 2

[0032] Example 2: Mix 500 kilograms of fly ash, 1000 kilograms of kaolin, and 40 kilograms of quicklime, feed into the reactor, add water to keep the liquid-solid volume ratio at 2:1, stir and soak, heat at 80°C for 7 hours, and cool Finally, separate the residue from the liquid, adjust the pH of the filtrate to about 8 and save it; wash the filter residue, and the water for washing the residue can be recycled for secondary use, and then mix the filter residue with 36.7% industrial hydrochloric acid to keep the liquid-solid volume ratio at 2:1, and stir in the reactor Soak, heat at 100°C for 7 hours, and separate residue from liquid after cooling to obtain filtrate. Mix the two filtrates 1:1, stir, adjust the pH value to about 4, and let it stand still to obtain the brown-red high-efficiency composite polyaluminum iron silicate (PAFSC) flocculant liquid of the present invention.

Embodiment 3

[0033]Example 3: Mix 500 kilograms of fly ash, 250 kilograms of kaolin, and 30 kilograms of quicklime, feed into the reactor, add water to keep the liquid-solid volume ratio at 2:1, stir and soak, heat at 50°C for 8 hours, and cool Finally, separate the residue from the liquid, adjust the pH of the filtrate to about 9 and store it; wash the filter residue, and the water for washing the residue can be recycled for secondary use, and then mix the filter residue with 36.7% industrial hydrochloric acid to keep the liquid-solid volume ratio at 1.5:1, and stir in the reactor Soak, heat at 60°C for 8 hours, and separate residue from liquid after cooling to obtain filtrate. Mix the two filtrates 1:1, stir, adjust the pH value to about 4, and let it stand still to obtain the brown-red high-efficiency composite polyaluminum iron silicate (PAFSC) flocculant liquid of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com