Method for preparing nano molecular sieve

A nano-scale molecular sieve and a synthesis method technology are applied in the field of nano-scale molecular sieve preparation, which can solve the problems of reducing water content and failing to synthesize nano-scale beta zeolite, and achieve the effect of avoiding the increase of crystal grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

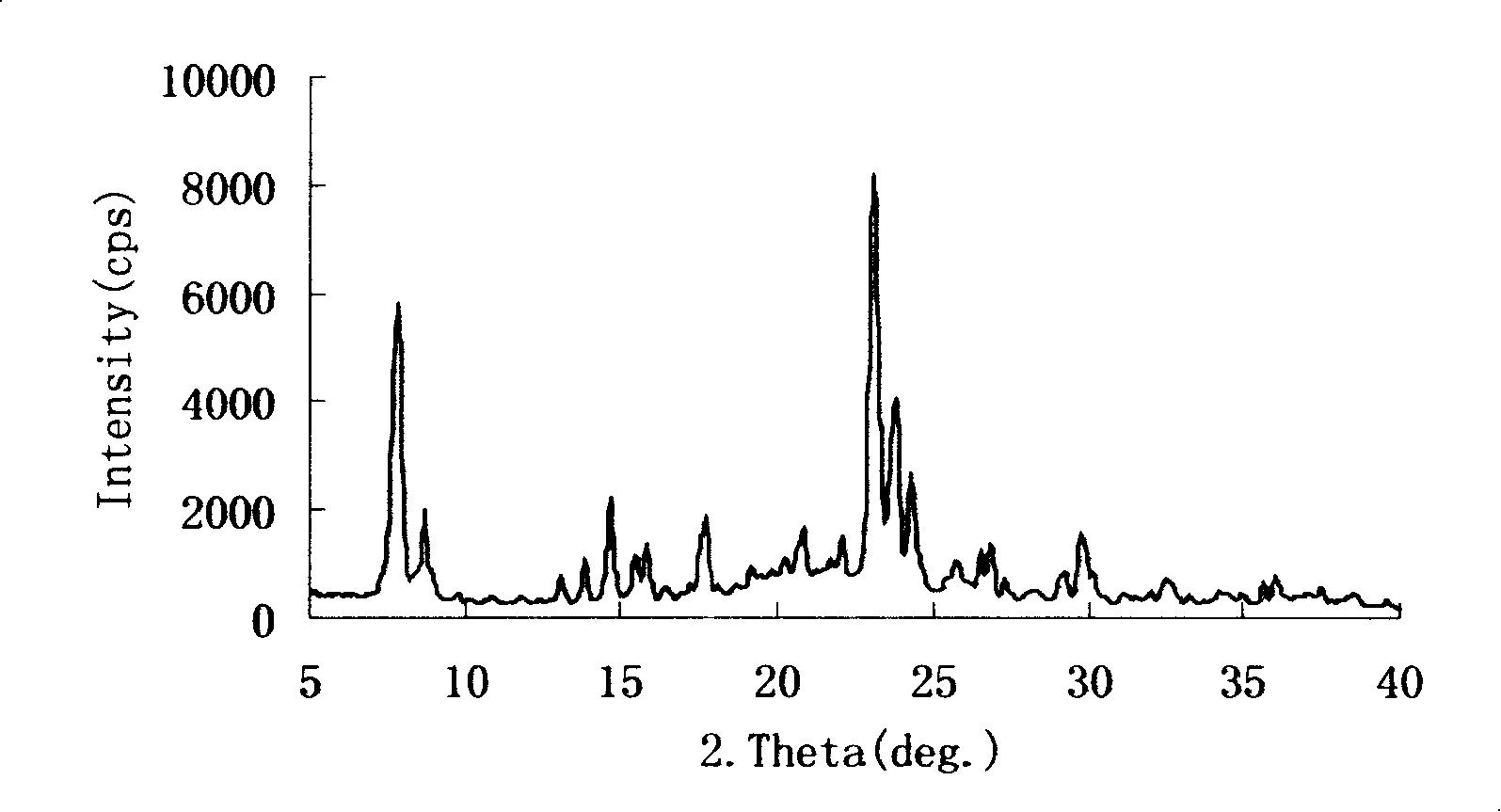

[0039] According to 0.02Al 2 o 3 : 1.0 SiO 2 : 0.08NH 4 HF 2 :0.06TMAOH:3H 2 O: 0.3C 2 h 5 The molar ratio of OH, 208g treated silica sol (200g of 408g 28wt% silica sol deep dehydration), 9.1g NH 4 HF 2 , 6.6gNaAlO 2 , 11gTMAOH, 15gH 2 O and 28gC 2 h 5 Mix OH with mechanical stirring (4000r / min) at room temperature, and continue to stir until the raw materials are evenly mixed to obtain a white sol-like silica-alumina gel. Mix 13.9g of second-line distillate oil and 0.5g of polyisobutylene triethanolamine maleate under mechanical stirring at 90°C and 4000r / min, then drop in 277.7g of silica-alumina gel, and stir until the raw materials are evenly mixed to obtain Stable hypersolubilized micelle system. Transfer to an autoclave, seal and crystallize statically at 140°C for 30 hours. The product was centrifuged, washed to neutral, dried at 110°C, calcined at 250°C for 2 hours, and then heated to 350°C for 5 hours to obtain a molecular sieve sample. Characterized by...

Embodiment 2

[0041] According to 1.0SiO2 2 : 0.02NH 4 F: 0.07 (C 2 h 5 ) 3 N:5H 2 0: The mol ratio of 0.5 ethylene glycol, 208g ethyl orthosilicate, 0.8g ammonium fluoride, 6.1g triethylamine, 54g water and 31g ethylene glycol are mixed under the mechanical stirring of 800rpm rotating speed at room temperature, and Continue to stir until the raw materials are evenly mixed to obtain white sol-like silica-alumina gel. 21.4g of the third-line distillate oil, 4.3g of polyisobutenyl diethylene glycol maleate and 4.3g of polyoxyethylene lauryl ether (10) were mixed under mechanical stirring at 90°C and 800rpm, and then slowly added 300g Silica-alumina gel, and stir until the raw materials are evenly mixed to obtain a stable supersolubilized micelle system. Transfer to an autoclave, seal and crystallize statically at 140°C for 30 hours. The product was characterized by XRD, BET and TEM after being treated as in Example 1. The characterization results show that the product Silicalite-1 is ...

Embodiment 3

[0043] According to 0.04Al 2 o 3 : 1SiO 2 :0.04KOH:0.05TPABr:2H 2 The molar ratio of O: 0.3 diethylene glycol, 120g white carbon black, 7.8g pseudo-boehmite, 2.7gTPABr, 4.5g KOH, 72gH 2 O and 63g of diethylene glycol were mixed at room temperature with mechanical stirring (rotating speed 1500rpm), and continued to stir until the raw materials were uniformly mixed to obtain white sol-like silica-alumina gel. Mix 33.8g of four-line distillate oil, 13.5g of SP-80 and 6.75g of lecithin at 90°C and 1000rpm under mechanical stirring, then slowly add 270g of silica-alumina gel and stir until the raw materials are evenly mixed to obtain a stable Hypersolubilized micellar system. Transfer to an autoclave, seal and crystallize statically at 120°C for 30 hours, calcine at 250°C for 3 hours, and then heat up to 350°C and calcine for 7 hours to obtain a molecular sieve sample. XRD, BET and TEM characterizations were carried out. The characterization results show that the product is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com