Single-cavity double-oscillator piezoelectric pump

A dual vibrator and piezoelectric pump technology, which is applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machinery, etc., can solve the problems of low output flow and limited output capacity of single-cavity piezoelectric pumps, and achieve improved The effect of output ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

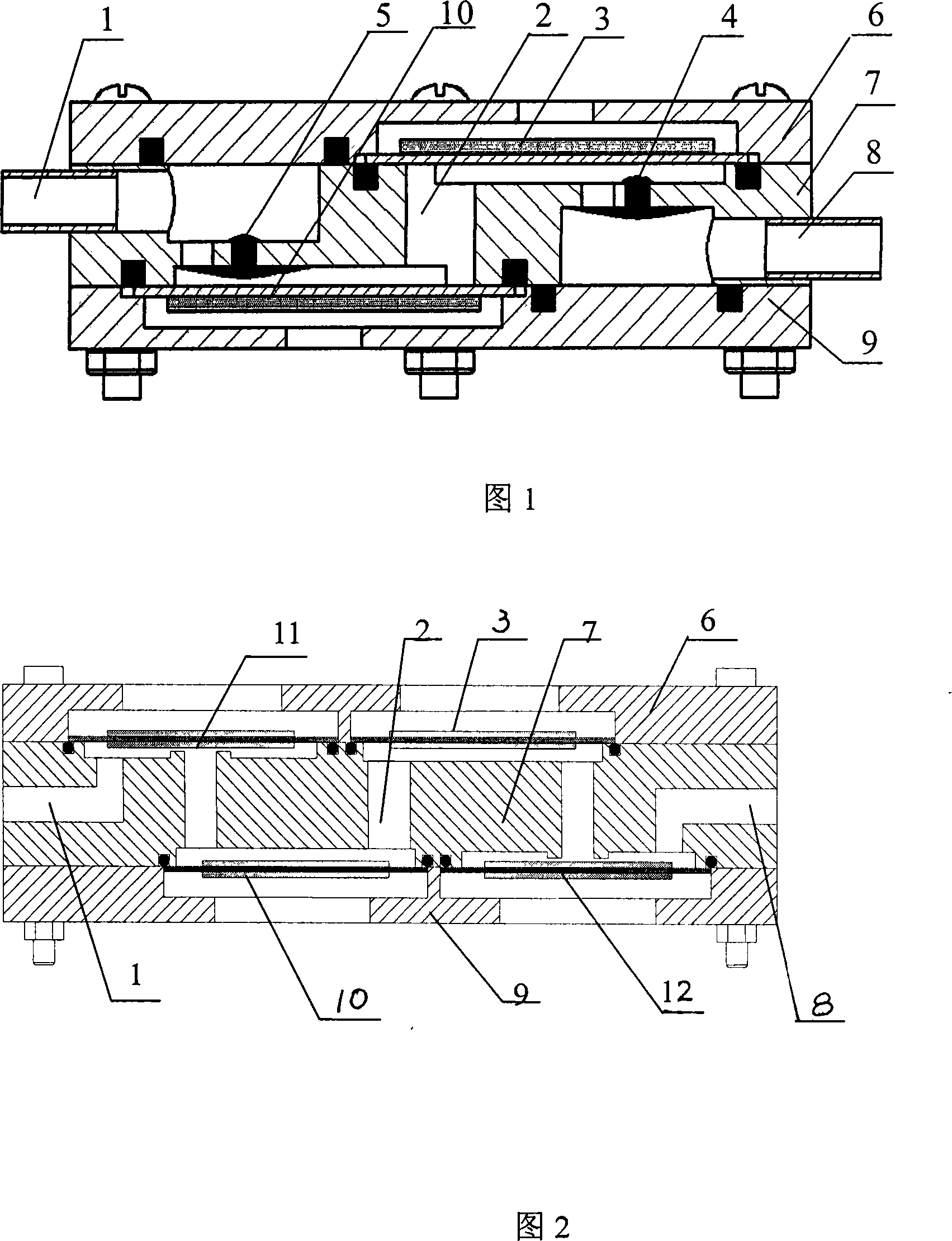

[0014] Referring to Fig. 1, the upper cover 6 and the lower cover 9 are fixedly connected to the pump body 7, the inlet pipe 1 and the outlet pipe 8 are fixedly connected to the water inlet and outlet of the pump body respectively, and the front part of the pump chamber 2 is fixedly connected to the pump chamber driving piezoelectric Vibrator one 10 is fixedly connected to the one-way passive valve one 5 at the water inlet of the pump chamber, fixedly connected to the pump chamber driving piezoelectric vibrator two 3 at the rear of the pump chamber 2, and fixedly connected to the one-way passive valve at the water outlet of the pump chamber Two 4.

[0015] Its working process has two states:

[0016] 1. The volume of the pump cavity is expanded. At this time, the piezoelectric vibrator expands outward at the same time, and the pressure in the pump body is lower than the external pressure. Under the action of the fluid pressure, the inlet valve opens, the outlet valve closes, a...

Embodiment 2

[0019] The upper cover 6 and the lower cover 9 are fixedly connected to the pump body 7, the inlet pipe 1 and the outlet pipe 8 are respectively fixedly connected to the water inlet and outlet of the pump body, and the front part of the pump chamber 2 is fixedly connected to the piezoelectric vibrator 10 driven by the pump chamber. The active valve one 11 is fixedly connected to the water inlet of the pump chamber, the pump chamber driving piezoelectric vibrator two 3 is fixedly connected to the rear of the pump chamber 2, and the active valve two 12 is fixedly connected to the water outlet of the pump chamber.

[0020] The first piezoelectric vibrator driven by the pump cavity and the second piezoelectric vibrator driven by the pump cavity adopt a bimorph circular piezoelectric vibrator. Active valve 1 and active valve 2 use a bimorph circular piezoelectric vibrator.

[0021] The working process of the pump is as follows:

[0022] 1. Apply an electrical signal to the piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com