Apparatus and method for titanium and titanium alloy surface oxygen-carbon co-cementation

A surface oxygen and titanium alloy technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems affecting the performance of titanium alloy substrate, shallow penetration layer, limited improvement of wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

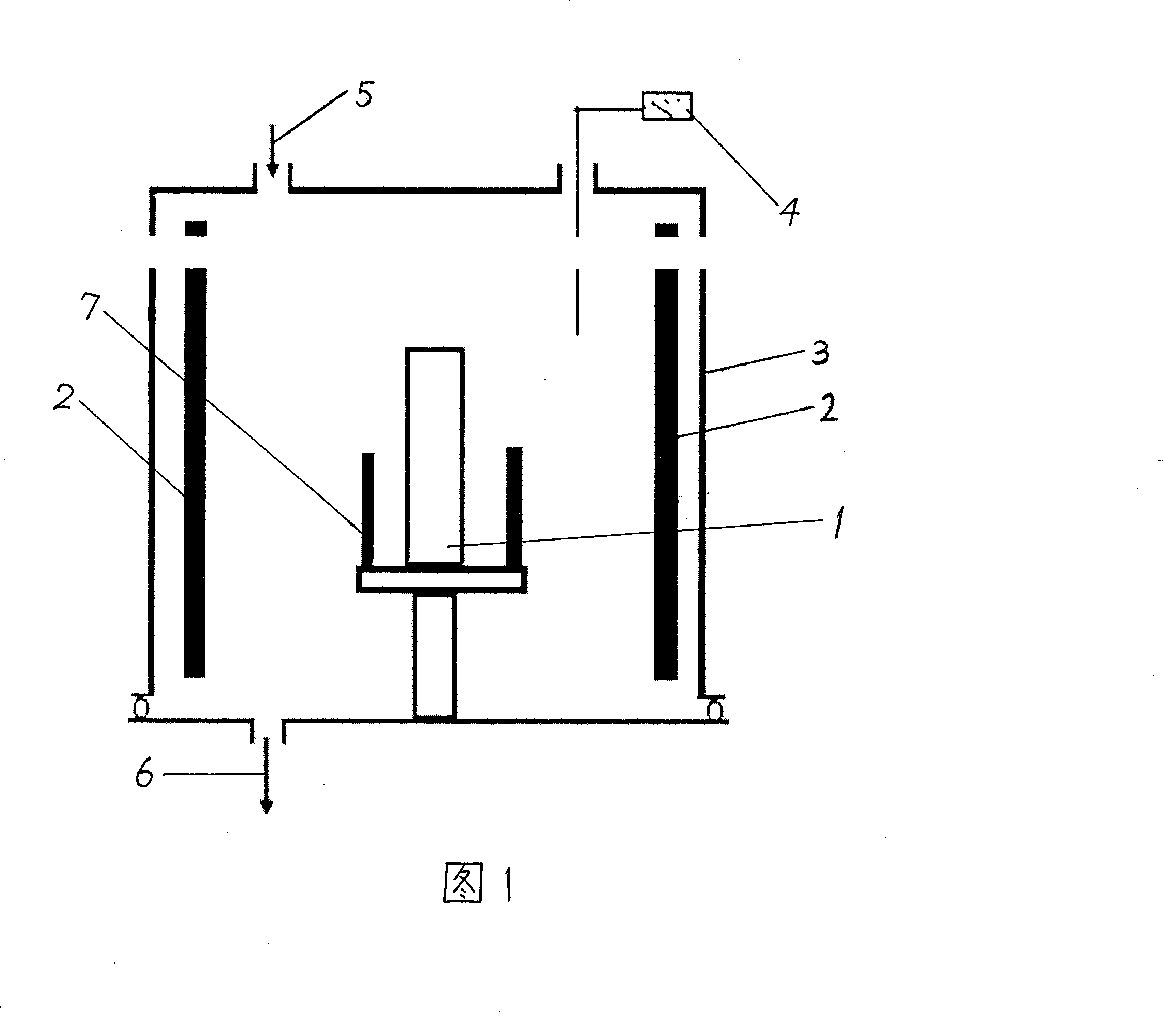

Image

Examples

Embodiment 1

[0019] Put the sample made of industrial titanium material TA1 into the vacuum chamber 3, and the vacuum reaches 5×10 -3 After Pa, the titanium material is heated to 1000°C, and 0.1Pa high-purity CO 2 Gas, gas partial pressure after 200 hours of reaction diffusion treatment, a 1000μm thick oxycarbide layer is formed on the titanium surface, and the surface hardness reaches HV1100.

Embodiment 2

[0021] Put the sample made of Ti6Al4V titanium alloy into the vacuum chamber 3, and the vacuum reaches 5×10 -3 After Pa, the titanium material is heated to 700°C, and 1000Pa high-purity CO 2 After 0.5 hours of reaction diffusion treatment, an oxycarbide layer with a thickness of 30 μm is formed on the surface of the titanium material, and the surface hardness reaches HV700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com