Plaster multi-step treatment device for underground engineering construction

An underground engineering and treatment device technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems that mud cannot be graded and the moisture content of slag is low, and achieve The effect of high solid phase separation precision, low sand content and strong formation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

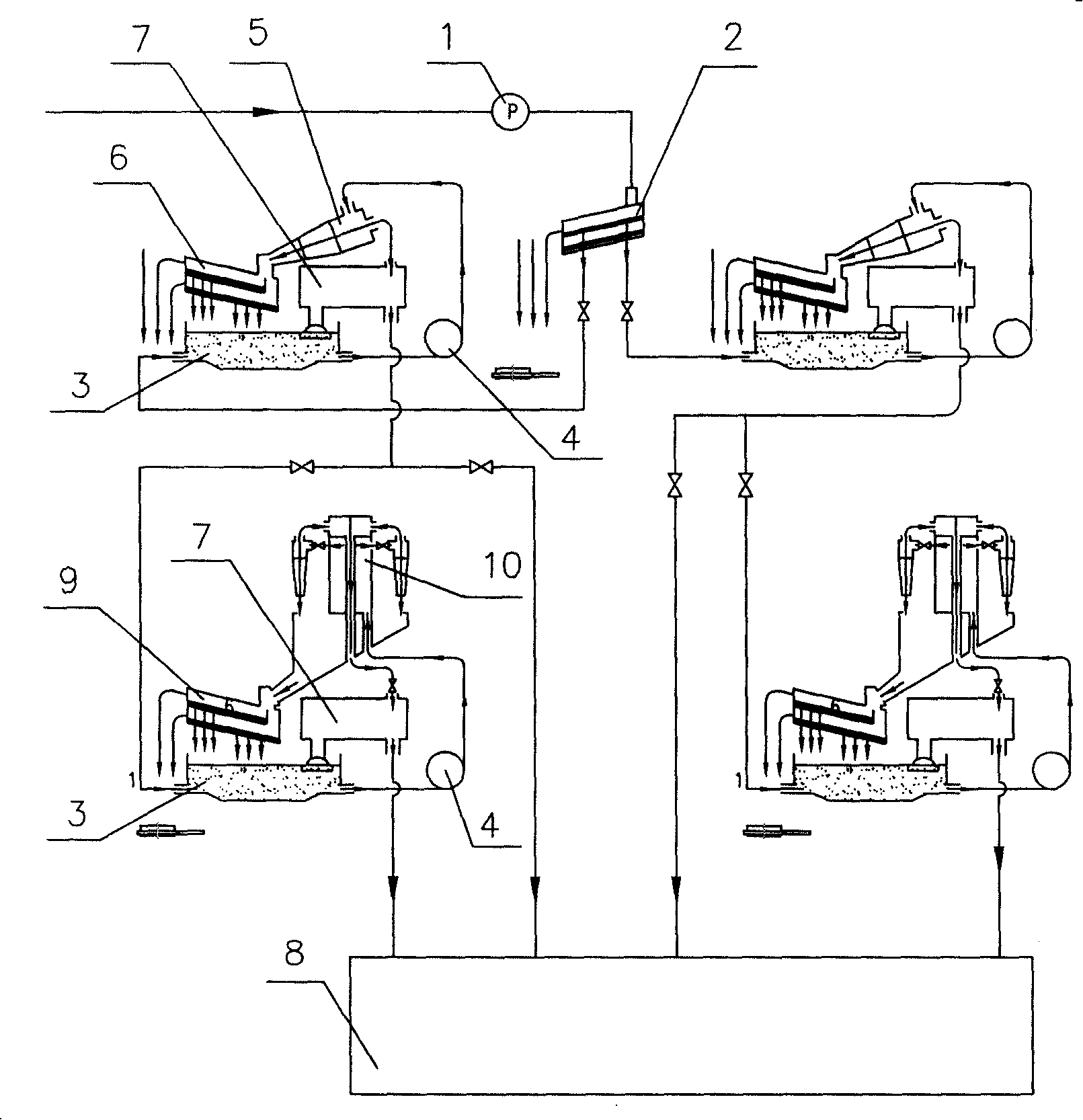

[0010] A multi-stage treatment device for mud and water in underground engineering construction, including a pre-screener 2, a desander, and a desilter. The mud discharge pump 1 is connected to the pre-screener 2 through a pipeline, and the mud outlet of the pre-screener is through a pipeline. It is connected to the inlet of the slurry storage tank 3 of the desander, the slurry outlet of the slurry storage tank is connected to the slurry inlet of the cyclone 5 through the slurry pump 4 and the pipeline, and the overflow pipe of the cyclone is connected to the middle storage of the desander The inlet of the tank 7 is connected, the grit nozzle at the lower end of the cyclone is connected to the desander sieve 6, the mud outlet of the desand screen is connected to the slurry storage tank 3, and the outlet of the middle storage tank 7 is respectively connected to the desilter through a switching valve and a pipeline. The slurry storage tank 3 of the slurry tank is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com