Method for producing polythene/POSS modified tough clay nano composite material

A nano-composite material and polyethylene technology is applied in the field of preparation of polyethylene/POSS modified clay nano-composite materials, which can solve the problems of high temperature resistance, poor mechanical properties of composite materials, adverse effects on material processing and performance, etc. The effect of avoiding thermal instability, simple preparation method, thermal stability and dynamic mechanical storage modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of acenaphthyldiimine ligand

[0034] 3.0 g of 4,4-methylene-bis(2,6-diisopropylaniline) and 0.54 g of acenaphthoquinone were dissolved in 50 ml of toluene solution, 2 ml of formic acid was added as a catalyst, and the mixture was refluxed for 14 hours. During the reflux process, a water separator was used to remove the moisture generated during the reaction. After the reflux was completed, the temperature of the solution was lowered to room temperature, and the solvent was evaporated in vacuo. The resulting crude product was purified by column (silica gel, ethyl acetate:petroleum ether=1:9) to obtain 1.2 g of N,N'-bis[4-(4-amino-3,5-diisopropylbenzyl )-2,6-diisopropylphenyl] acenaphthylenediimine ligand L, yellow powder. Ligand L 1 H-NMR (500MHz, CDCl 3 ) results: 7.89(d, 2H), 7.37(t, 2H), 7.01(s, 4H), 6.87(s, 4H), 6.74(s, 2H), 3.84(d, 4H), 3.53(s, 4H ), 2.19(s, 12H), 2.06(s, 12H); ligand L 13 C-NMR (500MHz, CDCl 3 )结果:161.016,145.358,140.787,137...

Embodiment 2

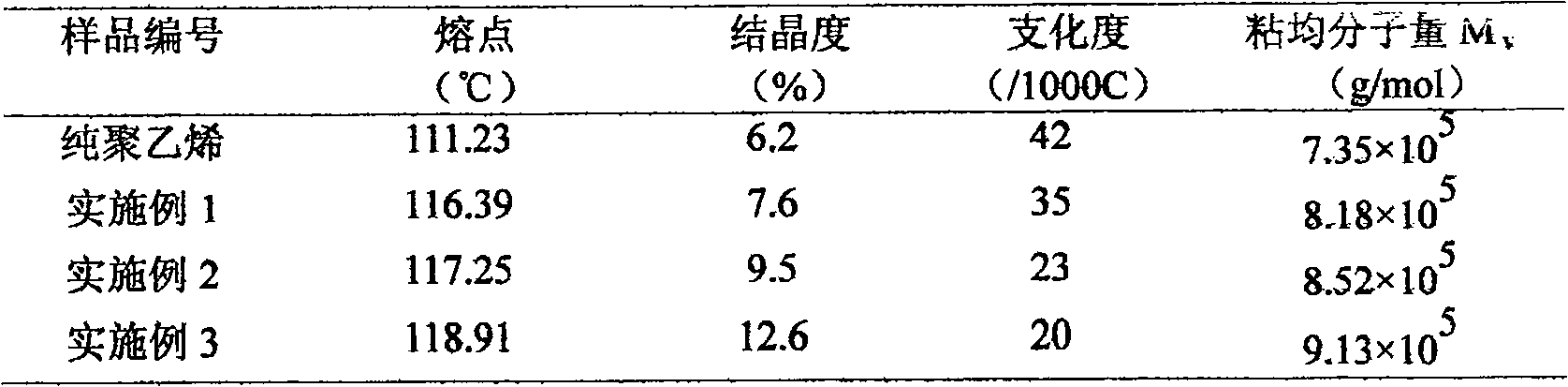

[0047] The other conditions of this embodiment are the same as in Example 1: the polymerization reaction time in step (6) is 80min. Under the above polymerization conditions, the branching degree, melting point, crystallinity and molecular weight of the obtained polyethylene are shown in Table 1. The POSS modified clay content is 6.2%. The thermal decomposition temperature of polyethylene / POSS modified clay nanocomposites is shown in Table 2. When 50% thermal weight loss is used as a comparison point, the degradation temperature of polyethylene composites is 471.9 ° C, which is higher than that of pure Polyethylene is 56.0°C higher. The storage modulus of polyethylene / POSS modified clay nanocomposites is shown in Table 3. At 20°C, the storage modulus of polyethylene composites is 989% higher than that of pure polyethylene.

Embodiment 3

[0051] The other conditions of this embodiment are the same as in Example 1: the polymerization reaction time in step (6) is 45min. Under the above polymerization conditions, the branching degree, melting point, crystallinity and molecular weight of the obtained polyethylene are shown in Table 1. The POSS modified clay content is 9.8%. The thermal decomposition temperature of polyethylene / POSS modified clay nanocomposites is shown in Table 2. When 50% thermal weight loss is used as a comparison point, the degradation temperature of polyethylene composites is 477.8 ° C, which is higher than that of pure Polyethylene is 61.9°C higher. The storage modulus of polyethylene / POSS modified clay nanocomposites is shown in Table 3. At 20°C, the storage modulus of polyethylene composites is 1226% higher than that of pure polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com