Method for manufacturing drainage bottle

A manufacturing method and technology of drainage bottles, which are applied to wound drainage devices and suction devices, etc., can solve problems such as the inability to fully guarantee the absolute safety of the drainage bottles, the difficulty in ensuring the airtightness of the drainage bottles, and the loose fit of the seals, etc., to achieve Eliminate hidden dangers of air leakage, avoid trachoma or tiny pores, and have good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

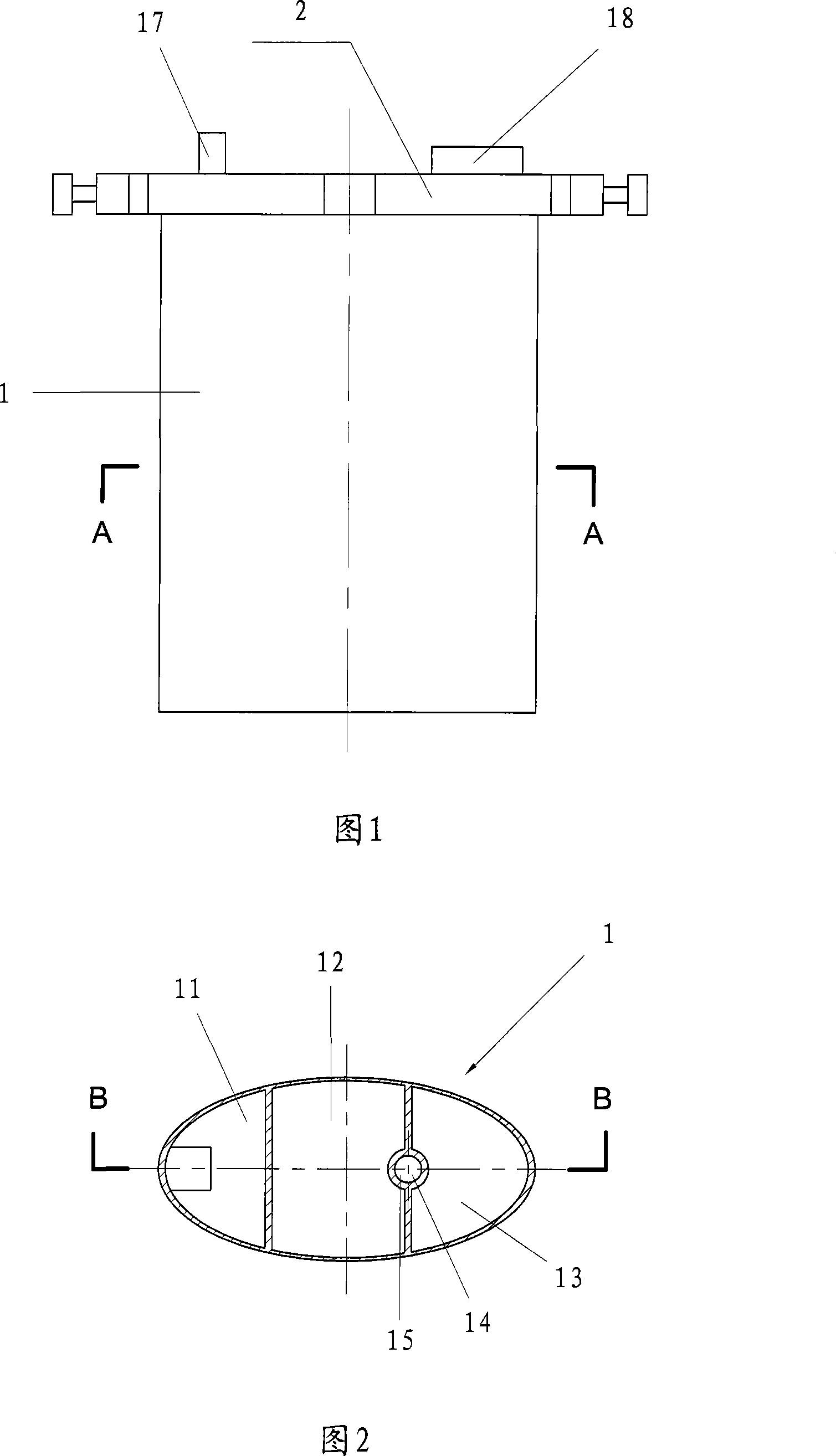

[0029] As shown in FIG. 1 , the drainage bottle implemented according to the present invention includes a bottle body 1 and a bottle cap 2 . The material of the bottle body 1 and the bottle cap 2 is transparent plastic, which is manufactured by injection molding process.

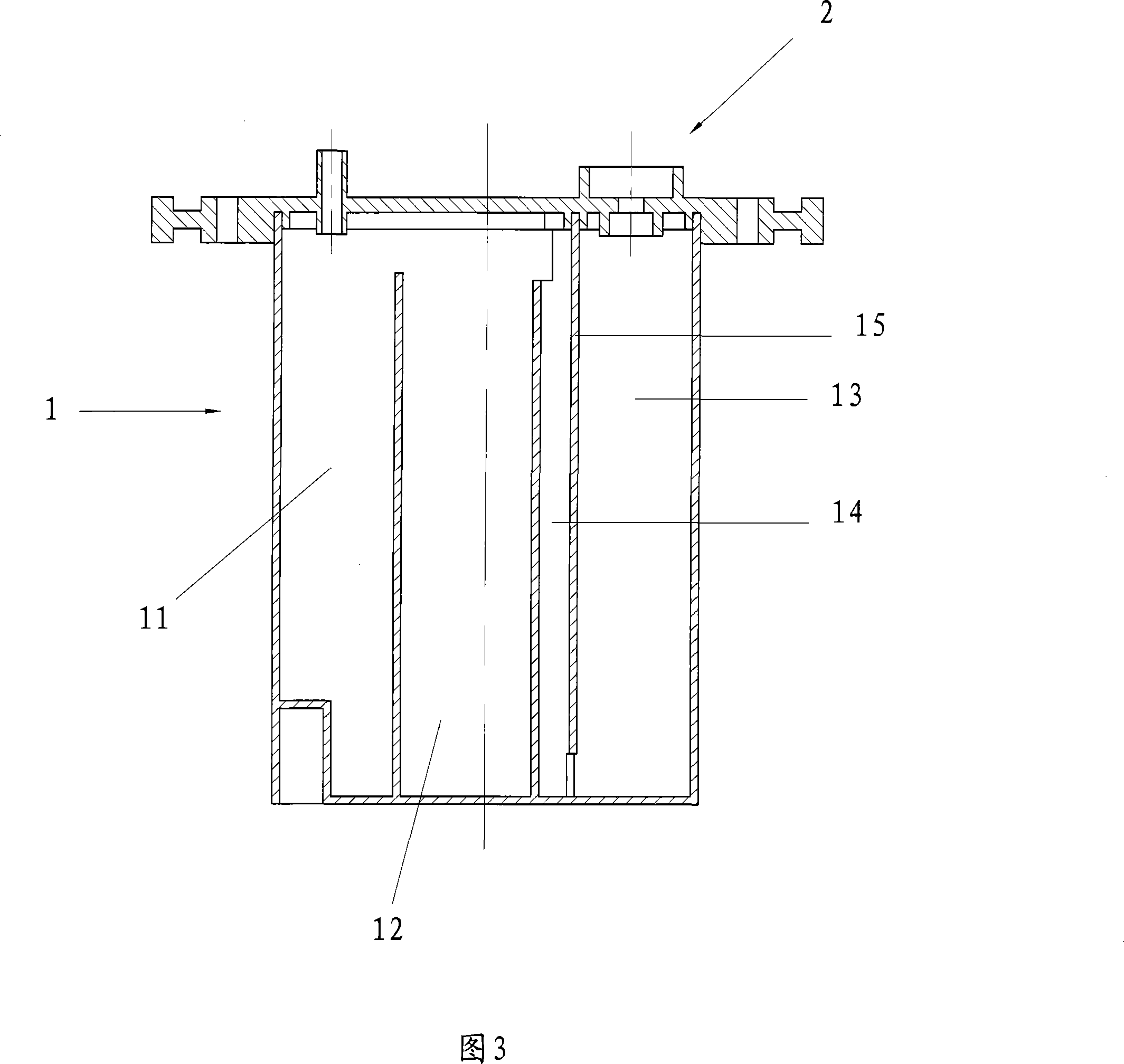

[0030] As shown in Figure 2 and Figure 3, the drainage bottle described in this embodiment is a double-chamber drainage bottle, and the bottle body 1 includes an outer sub-chamber 11 of the accumulation chamber and an inner sub-chamber of the accumulation chamber connected to each other at the upper end. 12. The water seal chamber 13 and the water seal pipe 14, wherein the water seal chamber 13 and the water seal pipe 14 are separated by partitions 15 with openings up and down, the upper edge of the partition 15 is in contact with the bottle The upper edge of the body 1 is at the same height. The bottle cap 2 is provided with a drainage tube inlet 17 for inserting the drainage tube into the sub-cavity 11 ou...

Embodiment 2

[0037] As shown in Figure 6, Embodiment 2 is a three-chamber drainage bottle. As shown in accompanying drawing 7 and accompanying drawing 8, the bottle body of this embodiment includes the sub-chamber 11 outside the accumulating chamber, the sub-chamber 12 inside the accumulating chamber, the water sealing chamber 13, the water sealing tube 14, the pressure regulating chamber 16, and the drainage tube. Inlet 17 , first liquid filling port 18 , second liquid filling port 19 , vent hole 20 . Wherein, the water-seal chamber 13 and the water-seal pipe 14 are separated by partitions 15 with upper and lower openings. Therefore, the shape of the bottle cap 2 in this embodiment is more complicated, and the requirements for the forming process and welding process are higher.

[0038] The welding wire 3 used in this embodiment is also a closed ring that completely corresponds to the shape of the installation groove 4, as shown in Figure 9, and its cross-sectional shape is an equilatera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com