Painting product with butter and vegetable oil as base and preparation method thereof

A vegetable oil and product technology, applied in the field of smear products and their production, smear products, to achieve the effect of smooth taste, easy to accept, low fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

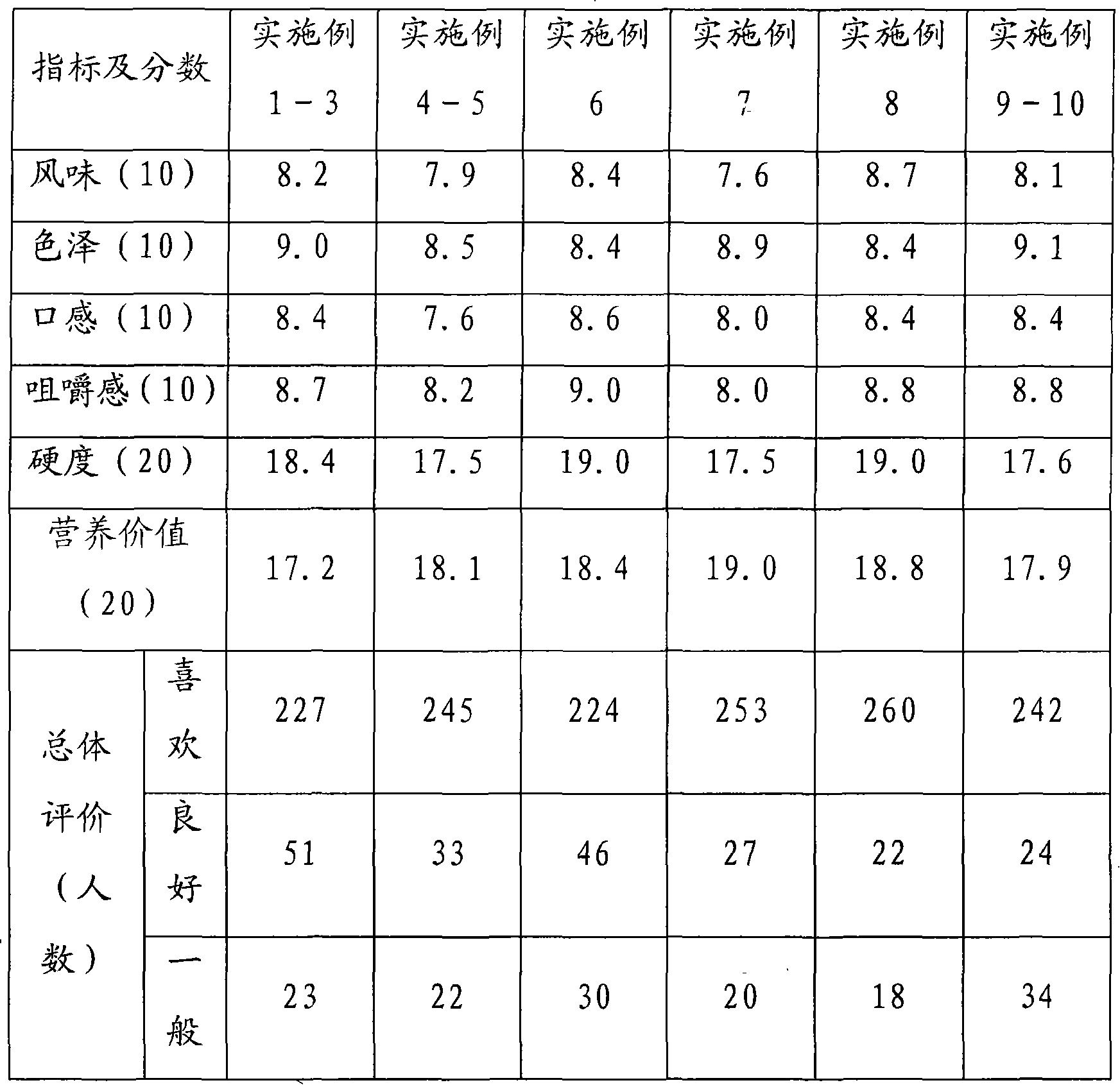

Examples

Embodiment 1

[0043] Embodiment 1 (balanced coordination scheme of butter and vegetable oil)

[0044] Formula (according to 1 ton):

[0045] Butter: 0.5 tons

[0046] 0.4 tons of vegetable oil (0.2 tons of sunflower oil, 0.1 tons of rapeseed oil, 0.1 tons of soybean oil)

[0047] h 2 O 0.1 ton

[0048] Raw material standard:

[0049] Butter: fat ≥ 80%

[0050] Mono-diglycerides and soy lecithin total 0.6%

[0051] Modified starch (tapioca or starch) pectin 1.0g / kg

[0052] β-carotene 0.1g / kg

[0053] Potassium sorbate 0.05: in line with national standards.

[0054] The development technological process of spread butter product of the present invention

[0055] Water phase and oil phase}→emulsion preparation→pasteurization→homogenization→cooling→packaging→freezing

[0056] Process points:

[0057](1) Water phase: including water, hydrophilic colloid: oil phase includes vegetable oil, emulsifier, butter.

[0058] (2) Emulsion preparation: raise the temperature of the water phase a...

Embodiment 2

[0067] Embodiment 2 (based on vegetable oil, adding functional vegetable oil simultaneously)

[0068] Formula (according to 1 ton):

[0069] Butter: 0.3 tons

[0070] 0.6 tons of vegetable oil (0.3 tons of sunflower oil, 0.25 tons of rapeseed oil, 0.05 tons of olive oil)

[0071] h 2 O 0.1 ton

[0072] Raw material standard:

[0073] Butter: fat ≥ 80%

[0074] Mono-diglycerides and soy lecithin total 0.6%

[0075] Modified starch (tapioca or starch) pectin 1.0g / kg

[0076] β-carotene 0.1g / kg

[0077] Potassium sorbate 0.05: in line with national standards.

[0078] The development technological process of spread butter product of the present invention

[0079] water box

[0080] Oil phase}→emulsion preparation→pasteurization→homogenization→cooling→packaging→freezing

[0081] Process points:

[0082] (1) Water phase: including water, hydrophilic colloid: oil phase includes vegetable oil, emulsifier, butter.

[0083] (2) Emulsion preparation: raise the temperature o...

Embodiment 3

[0092] Embodiment 3 (based on butter, adding multiple functional vegetable oils simultaneously)

[0093] Formula (according to 1 ton):

[0094] Butter: 0.8 tons

[0095] 0.1 tons of vegetable oil (0.03 tons of safflower oil, 0.01 tons of sesame oil, 0.06 tons of tea oil)

[0096] h 2 O 0.1 ton

[0097] Raw material standard:

[0098] Butter: fat ≥ 80%

[0099] Mono-diglycerides and soy lecithin total 0.6%

[0100] Modified starch (tapioca or starch) pectin 1.0g / kg

[0101] β-carotene 0.1g / kg

[0102] Potassium sorbate 0.05: in line with national standards.

[0103] The development technological process of spread butter product of the present invention

[0104] water box

[0105] Oil phase}→emulsion preparation→pasteurization→homogenization→cooling→packaging→freezing

[0106] Process points:

[0107] (1) Water phase: including water, hydrophilic colloid: oil phase includes vegetable oil, emulsifier, butter.

[0108] (2) Emulsion preparation: raise the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com