A conductive film for electromagnetic shielding and its making method

A conductive diaphragm and electromagnetic shielding technology, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve problems such as complex procedures, complex processes, and affecting shielding effects, so as to ensure shielding effects, use convenience, and The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

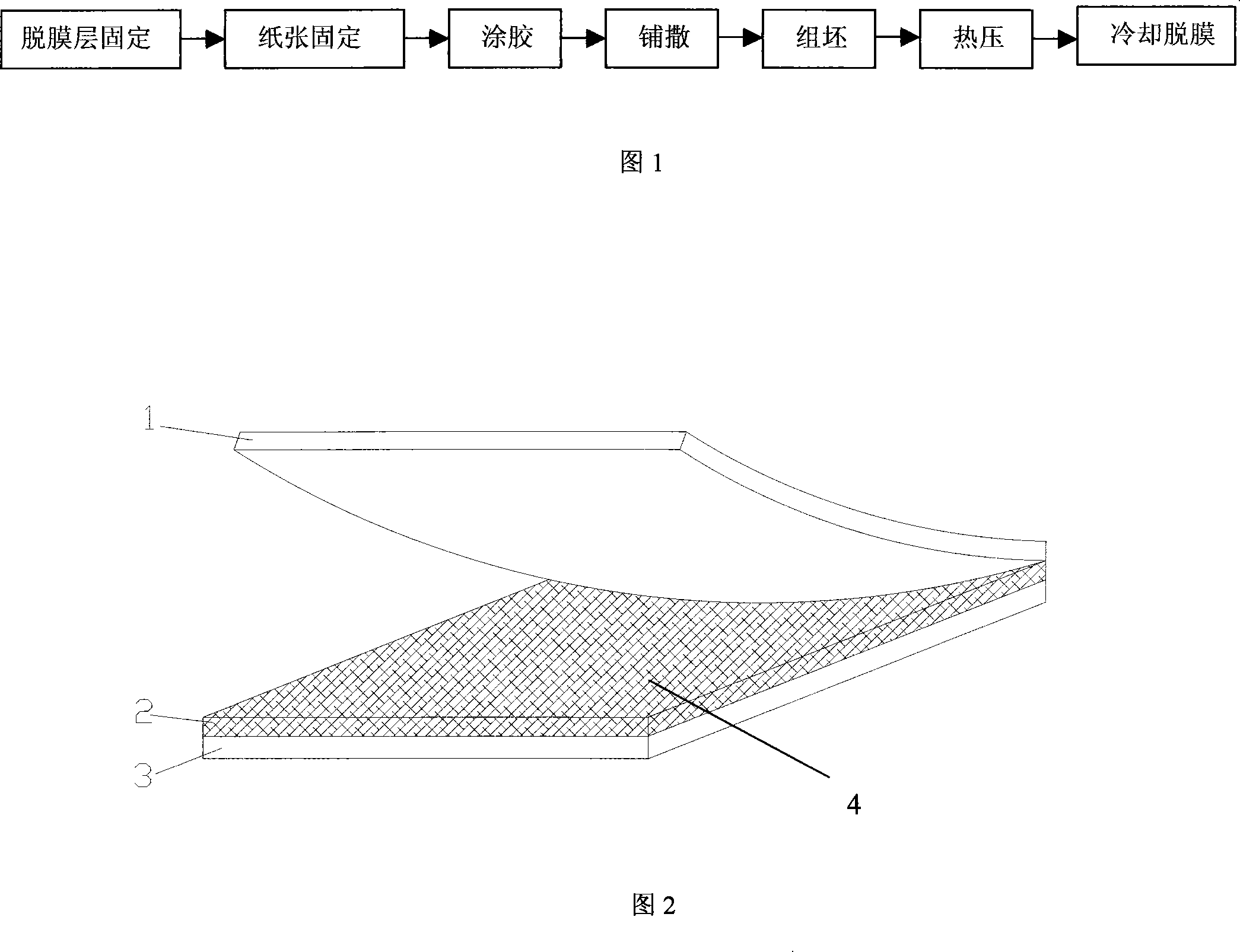

[0024] As shown in Figure 1, the manufacturing method of the conductive diaphragm that the present invention is used for electromagnetic shielding is specifically as follows:

[0025] 1) Adhere the polytetrafluoroethylene film as a release layer on the wood veneer, and spread the paper on the polytetrafluoroethylene film to prevent the mixed resin applied in the next step from penetrating the paper and sticking to the wood veneer. Together;

[0026] 2) glue coating, coating the mixed resin on the paper;

[0027] 3) apply the shielding material, spread the shielding material evenly on the paper by means of screen vibration, the shielding material can be stainless steel fibers with a diameter of 60 microns and a length of 5 mm and / or 10 mm and / or 15 mm or Brass fibers; also carbon fibers with a diameter of 10 microns and a length of 1 mm and / or 5 mm.

[0028] 4) Cover the spreaded shielding material again with paper coated with mixed resin on the surface, and form a blank;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com