Preparation process of carbon base sliding block material for track vehicle

A technology for rail vehicles and manufacturing processes, applied in vehicle parts, conductive materials dispersed in non-conductive inorganic materials, electric vehicles, etc. Excellent electrical conductivity and friction and wear properties, excellent comprehensive properties, good bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

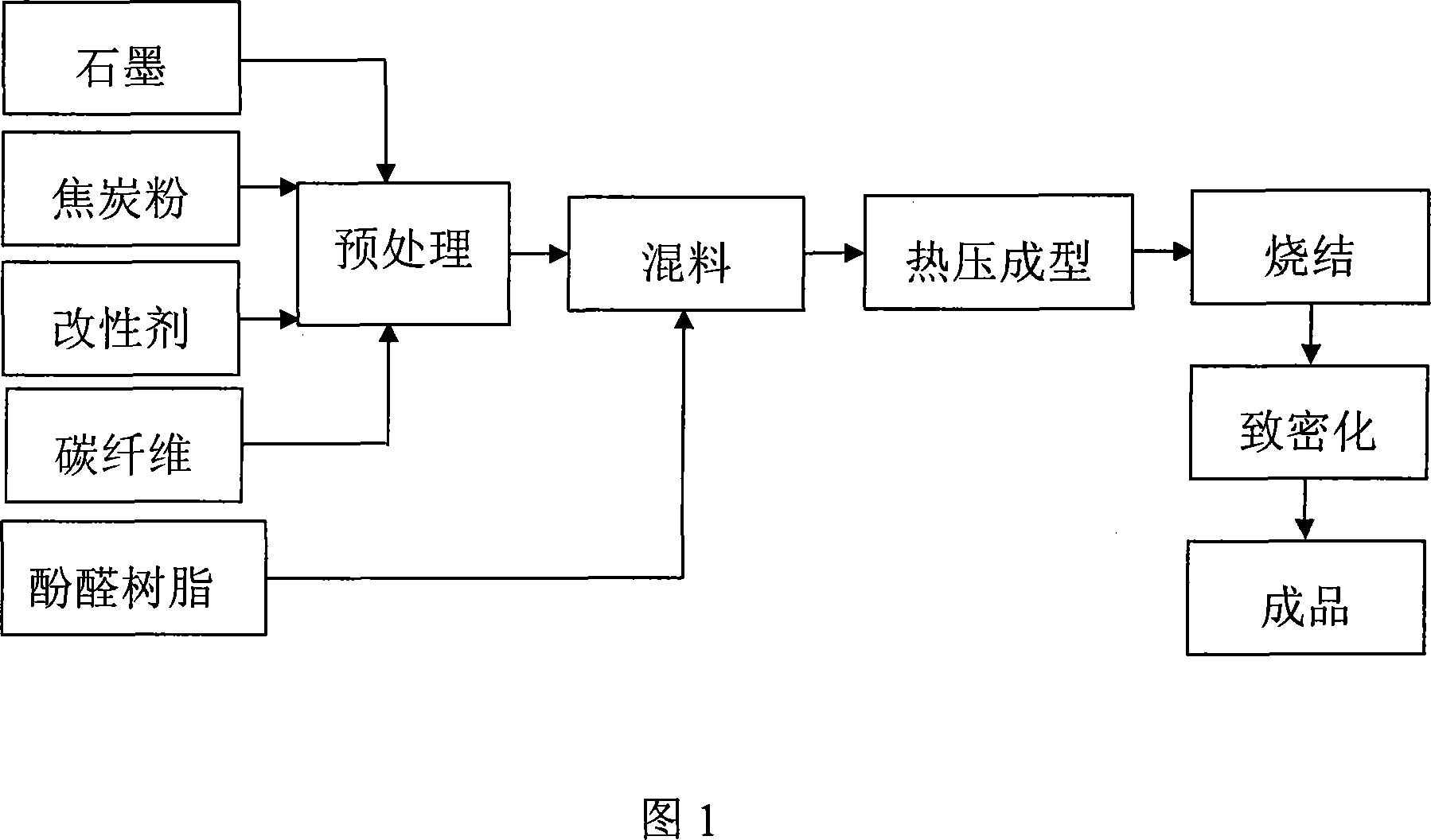

Method used

Image

Examples

Embodiment 1

[0039] The carbon-based composite material contains 15wt% of graphite, 25wt% of coke powder, 20wt% of copper powder, 5wt% of copper fiber, 3wt% of carbon fiber, 3wt% of molybdenum disulfide, 4wt% of alumina, 5wt% of glass powder and 20wt% of phenolic resin. Dry mixing method, after mixing evenly, first hot press at 80MP molding pressure and 165°C temperature for 30 minutes; then sinter the prepared sample at 800°C for 2 hours; finally put the sintered sample into the chemical vapor phase In a deposition furnace, use propane as a deposition gas source, and deposit at a temperature of 1000° C. for 10 hours. The density of the finished skateboard is 2.20g / cm 3 , the resistivity is 4.9×10 -6 Ω·m, the bending strength is 70MP, and the friction coefficient is 0.15.

Embodiment 2

[0041] The carbon-based composite material contains 20wt% of graphite, 15wt% of coke powder, 15wt% of copper powder, 10wt% of copper fiber, 5wt% of carbon fiber, 3wt% of molybdenum disulfide, 5wt% of alumina, 5wt% of glass powder and 22wt% of phenolic resin. Dry mixing method, after mixing evenly, first hot press at 100MP molding pressure and 165°C temperature for 1 hour; then sinter the prepared sample at 800°C for 2 hours; finally put the sintered sample into the chemical vapor phase In a deposition furnace, use propane as a deposition gas source, and deposit at a temperature of 1000° C. for 10 hours. The density of the prepared slide is 2.31g / cm 3 , the resistivity is 4.0×10 -6 Ω·m, the bending strength is 85MP, and the friction coefficient is 0.08.

Embodiment 3

[0043]The carbon-based composite material contains 15wt% of graphite, 15wt% of coke powder, 20wt% of copper powder, 5wt% of carbon fiber, 5wt% of molybdenum disulfide, 5wt% of alumina, 5wt% of glass powder and 30wt% of phenolic resin. After mixing evenly, first press at 60MP molding pressure and 165°C for 1 hour; then sinter the prepared sample at 800°C for 2 hours; finally impregnate the sintered sample with mesophase pitch at an atmospheric pressure 2 After 1 hour, the temperature was raised to 1100° C. at a rate of 10° C. / h and kept for 2 hours. The prepared slideboard has a density of 2.25g / cm 3 , the resistivity is 9.5×10 -6 Ω·m, the bending strength is 62MP, and the friction coefficient is 0.13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com