Method for producing two-dimensional polymer photon crystal using flexible offset printing

A lithography and photonic crystal technology, which is applied in the field of soft lithography to make two-dimensional polymer photonic crystals, can solve the problems of low modulus of PDMS templates, and achieve the effect of high fidelity and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

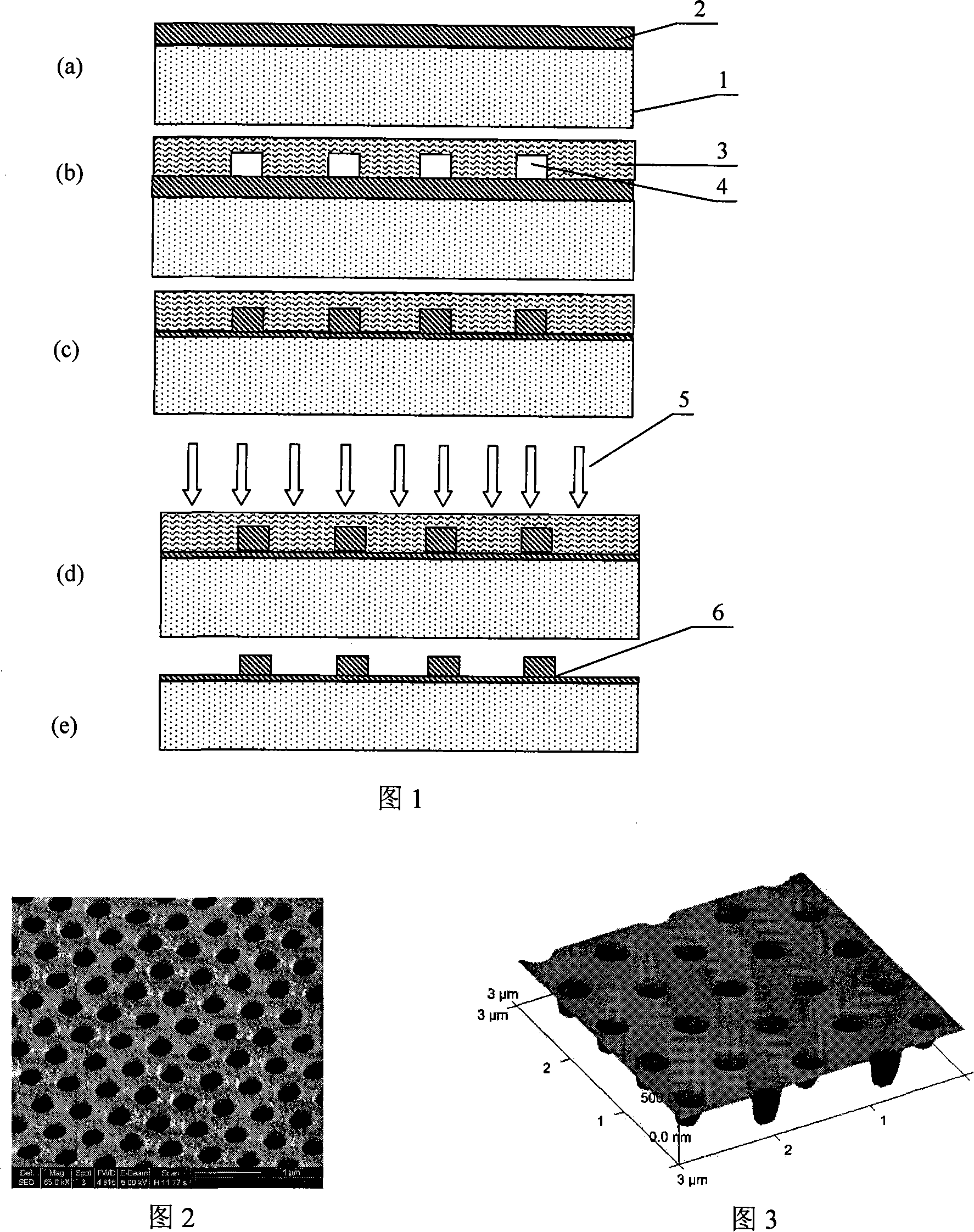

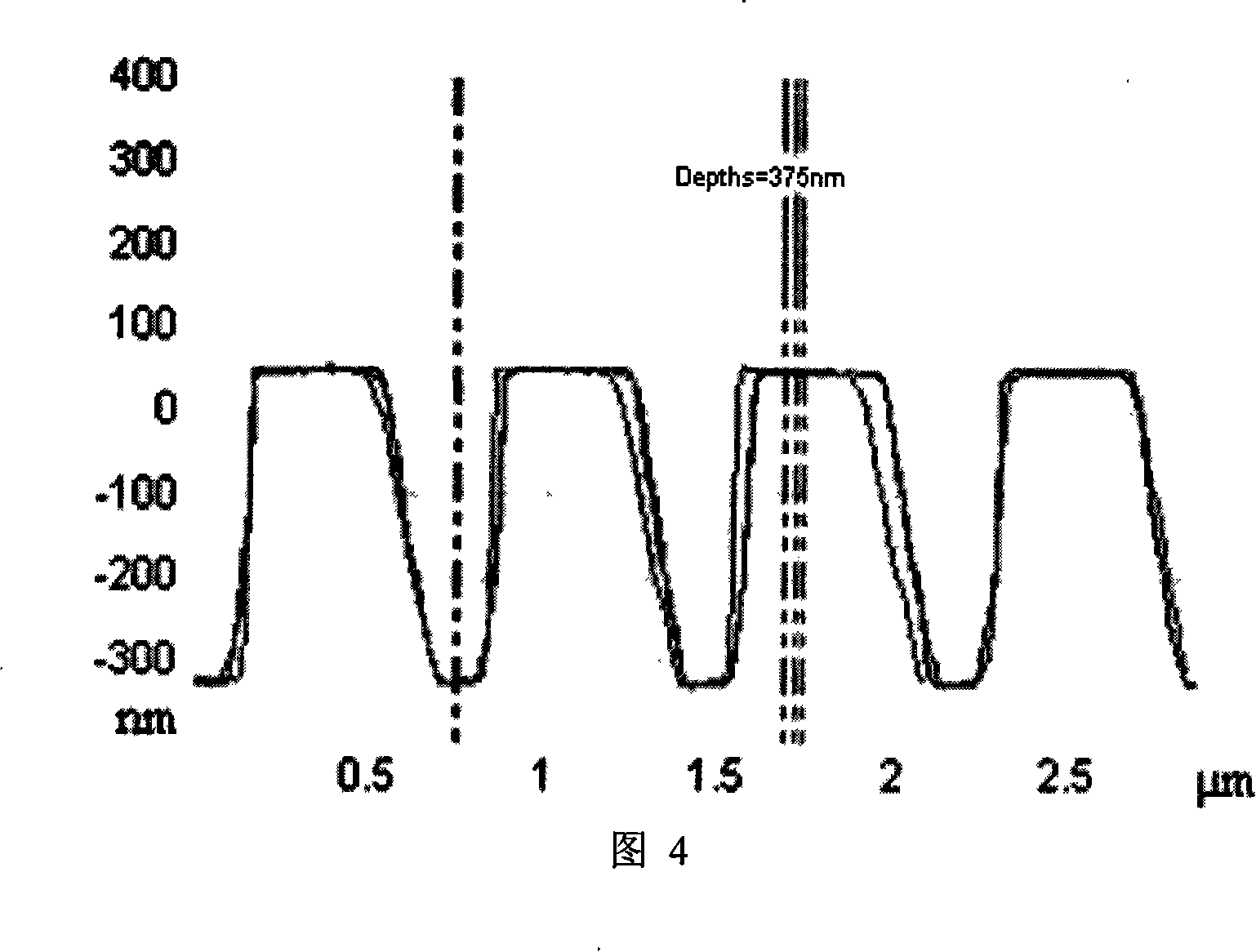

[0032] Example 1: Fabrication of two-dimensional ultraviolet acrylic polymer photonic crystals.

[0033] Materials used in the examples are as follows:

[0034] The ultraviolet acrylic polymer model WIR30-470 is produced and sold by ChemOptics, Korea.

[0035] The electronic etchant is ZEP520A, produced and sold by Japan ZEON Company.

[0036] ZED-N50 solvent: developer for electronic etching adhesive ZEP520A, produced and sold by Japan ZEON Company.

[0037] The PDMS model is Sylgard 184, with a specific gravity of 1.11 and a viscosity of 5000cSt, produced and sold by Dow Coming.

[0038] Proceed as follows:

[0039] (1) Substrate fabrication of triangular cavity structure

[0040]Using JEOL JBX6000 electron beam lithography (EBL) equipment, a layer of electronic etching glue (ER) ZEP520A is coated on the silicon substrate, the pattern is determined and printed by EBL, and the exposed electronic etching glue is in ZED-N50 solvent After development, bake on a baking tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com