Method for preparing nano alkaline-earth metal sulfate powder with different crystal morphology

An alkaline earth metal salt and alkaline earth metal technology, applied in the fields of calcium/strontium/barium sulfate, chemical instruments and methods, inorganic chemistry, etc. and other problems to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

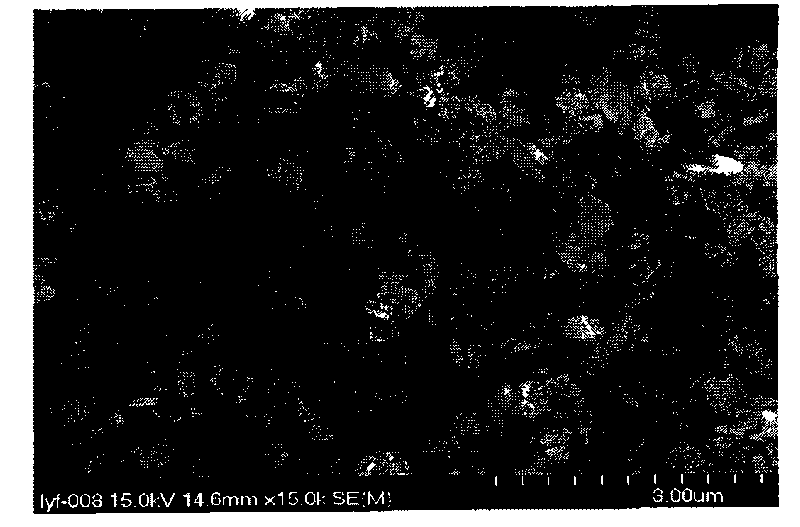

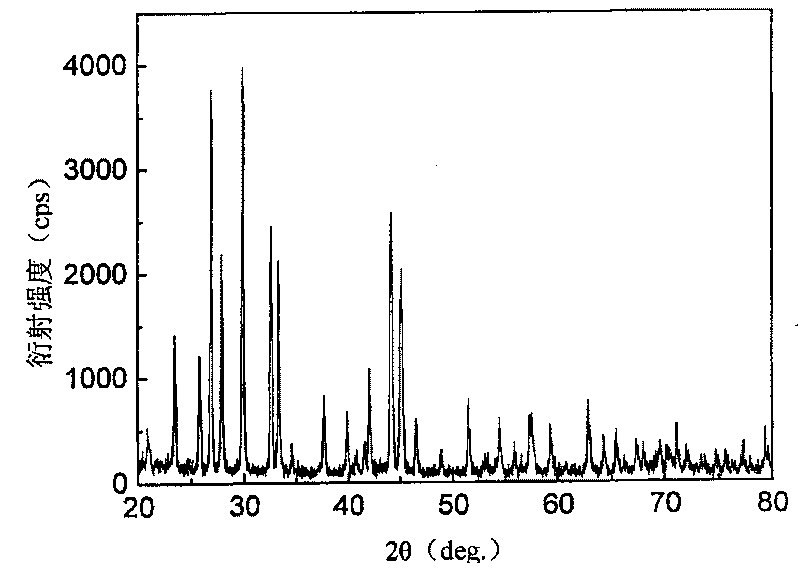

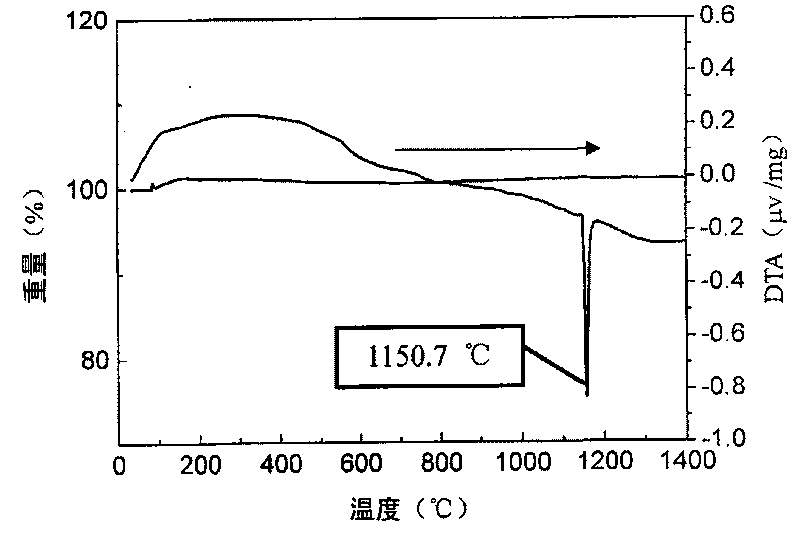

Image

Examples

specific Embodiment approach 1

[0006] Specific embodiment one: the method for preparing nano alkaline earth metal sulfate powders with different crystal shapes in this embodiment is completed by the following steps: one, at room temperature, utilize soluble alkaline earth metal salts and sulfates to prepare concentrations of 0.5~1.5mol / L alkaline earth metal salt solution and sulfate solution; 2. Under the condition of stirring the alkaline earth metal salt solution at a speed of 100~300rpm, add absolute ethanol into the alkaline earth metal salt solution and mix well, and the added anhydrous The volume of ethanol is 30-60% of the alkaline earth metal salt solution volume; 3. Under the stirring condition with 500~1000rpm speed, the sulfate solution is quickly added in the mixed solution, and the volume of the sulfate solution added is the 1 to 1.5 times the volume of the alkaline earth metal salt solution, add and continue to stir for 20 to 30 minutes, and the obtained precipitate is washed by centrifugal wa...

specific Embodiment approach 2

[0007] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the alkaline earth metal salt in step one is a kind of alkaline earth metal chloride or alkaline earth metal nitrate, and the described alkaline earth metal nitrate is calcium nitrate, One or a combination of barium nitrate and strontium nitrate, and the alkaline earth metal chloride is one or a combination of calcium chloride, barium chloride, and strontium chloride.

[0008] When the alkaline earth metal salt is a combination of calcium nitrate and barium nitrate, or a combination of calcium chloride and barium chloride, the molar ratio of Ca to Ba is 2:3; when the alkaline earth metal salt is a combination of calcium nitrate and strontium nitrate When the alkaline earth metal salt is a composition of strontium nitrate and barium nitrate, or a composition of strontium chloride and barium chloride, the molar ratio of Ca to Sr is 7:3; At this time, the molar ratio of Sr to Ba...

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the sulfate in step one is Na 2 SO 4 or K 2 SO 4 kind of. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com